Walk into any busy Los Angeles kitchen, from a Los Angeles food truck slinging carnitas to a high-end pizzeria ladling out fresh marinara, and you'll see one thing in common: the steam table pan full size. It’s the simple, rectangular workhorse that truly forms the backbone of almost every commercial kitchen—the foundational building block for getting food to customers efficiently.

The Unsung Hero of Every Commercial Kitchen

Look around any professional kitchen, and you’ll spot them everywhere. The full size steam table pan is so much more than a simple container. It's the key piece of a standardized system that lets chefs prep, cook, hold, and serve with incredible precision.

Think of it as a modular toolkit for food—a culinary version of LEGOs. This system gives a busy service line endless flexibility, and that standardization is the real secret to operational speed. This is true for all types of Los Angeles restaurants, from a busy spot serving Mexican food to a gourmet pizza parlor.

The whole system is built around one specific, industry-wide measurement. A full-size pan, often called a "full hotel pan," clocks in at roughly 20.75 x 12.75 inches. These dimensions are designed to perfectly fill a single steam table opening, creating a universal fit that kitchens everywhere rely on. This fractional system is what lets you mix and match smaller pans (like half or third sizes) to completely customize your serving line for whatever’s on the menu.

The genius of the steam table pan system lies in its interchangeability. A chef can cook macaroni and cheese in a full-size pan in the oven, then slide that same pan directly into a steam table for holding, and finally place it on a buffet line for serving—all without transferring the food.

That kind of efficiency is non-negotiable for any food service operation, whether it's a Mexican food restaurant juggling multiple salsas and toppings or a Los Angeles pizza spot keeping different pastas perfectly warm. It cuts down on labor, minimizes food waste, and makes temperature control a breeze, making it an indispensable asset.

Understanding how to use these pans effectively is a must for any serious culinary professional; it's a core part of any comprehensive commercial kitchen equipment checklist. Mastering this simple tool is the first step toward building a truly efficient and successful kitchen.

Mastering Pan Sizes and Capacities

The full-size steam table pan is the undisputed workhorse of any commercial kitchen. Think of it as the foundation, the master template from which a whole system of organization is built. It’s a bit like a game of kitchen Tetris—the goal is to perfectly fit different pans into a steam table well or a chafing dish frame, leaving no wasted space.

This simple but brilliant system is how a Los Angeles food truck can offer a dozen different toppings in a tiny footprint, or how a local Mexican food restaurant can line up its rice, beans, and various meats side-by-side, hot and ready to serve.

Understanding how the smaller, fractional pans nest inside that full-size footprint is one of those fundamental skills that separates a chaotic kitchen from a smooth-running one. The logic is beautifully simple: two half-pans fit perfectly into the space of one full-size pan. You can also swap in three third-pans, or even six sixth-pans into that exact same slot. This modular setup gives you incredible control over your serving line.

Breaking Down the Fractional System

This system is all about making every single inch of your steam table work for you. For instance, in a single full-size well, you could set up:

- One full-size pan holding a massive batch of scrambled eggs for the morning rush.

- Two half-pans, maybe one with breakfast potatoes and the other with bacon.

- A combo of one half-pan (for sausage) and three sixth-pans (for diced onions, peppers, and cheese).

The ability to mix and match on the fly means you can adapt to menu changes, manage inventory, and use your hot-holding restaurant equipment efficiently. No more wasted space or energy.

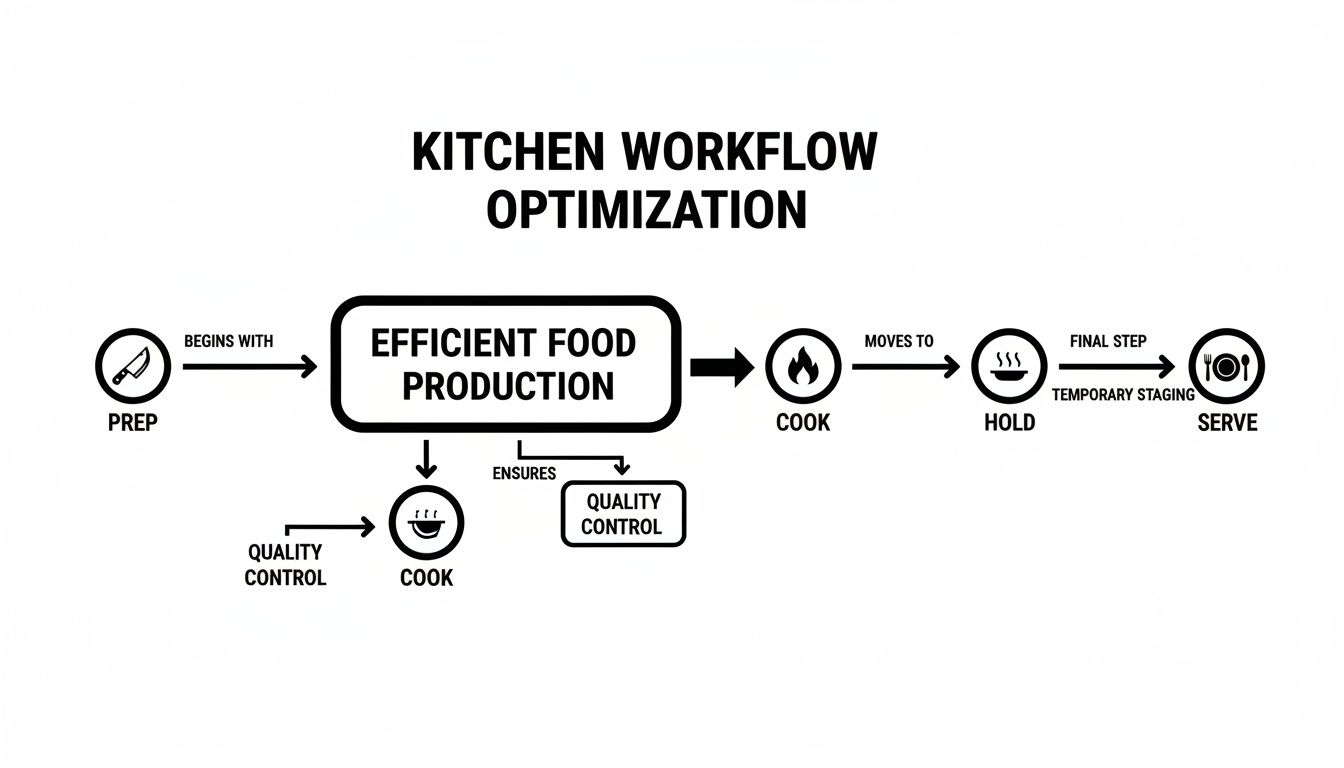

This diagram shows how a single pan moves through a typical kitchen, from the prep station all the way to the serving line.

You can see the pan is a constant, versatile tool used at every stage. That’s exactly why having standardized sizes is so critical to keeping things running smoothly.

Once you master these fractional pan combinations, you'll see a real improvement in service speed and food presentation. It’s a core skill that directly impacts your kitchen’s efficiency, leading to a more organized and visually appealing buffet line that your customers will definitely notice.

Steam Table Pan Sizes and Common Uses

To help you visualize your setup and plan your next order, here’s a quick-reference guide to standard pan sizes. Keep in mind that the exact capacity can vary a bit depending on the manufacturer and the pan’s depth, but these numbers are a solid starting point for planning your inventory.

| Pan Size | Nominal Dimensions (Inches) | Typical Capacity (Quarts) for 2.5" Depth | Example Use Case |

|---|---|---|---|

| Full Size | 20.75" x 12.75" | ~8.5 qt | Main entrees like roasted chicken, lasagna, or a big batch of mac and cheese. |

| Half Size | 12.75" x 10.38" | ~4 qt | Popular side dishes like mashed potatoes, green beans, or rice pilaf. |

| Third Size | 12.75" x 6.88" | ~2.5 qt | Meats for a taco bar (carnitas, al pastor, pollo asado) or Los Angeles pizza toppings. |

| Sixth Size | 6.88" x 6.25" | ~1 qt | Condiments and smaller toppings like salsa, sour cream, jalapeños, or shredded cheese. |

Getting the right mix of these pans is key. It ensures your hot line is not only functional but also flexible enough to handle whatever the day’s service throws at you.

How to Choose the Right Pan Material and Gauge

Picking the right steam table pan full size isn't just about getting the dimensions right. The real secret to a pan that lasts is in its material and thickness—two things that will make or break your investment in a busy Los Angeles kitchen.

When it comes to materials, you’re basically looking at a classic showdown: stainless steel versus aluminum. Each one has its place, and knowing the difference will save you a lot of headaches down the road.

Stainless Steel: The Industry Standard

Let’s be honest, for most high-volume kitchens, stainless steel is the undisputed champ. It’s tough as nails, laughs off rust and corrosion, and couldn't care less about acidic foods. That makes it the go-to for a Los Angeles pizza joint holding vats of marinara or a Mexican food spot with citrus-marinated carne asada.

The real beauty of stainless steel is its heat retention. It holds a consistent temperature like a pro, keeping your food safe and delicious for hours. These pans are true workhorses, built to bounce from the oven to the steam table to the dish pit, day in and day out. They’re a foundational piece of restaurant equipment, just like a reliable stainless kitchen prep table.

Aluminum: The Lightweight Alternative

Then you have aluminum. These pans are all about being lightweight and quick on the draw with heat. They heat up fast and cool down just as quickly, which can be a huge plus in certain situations.

You'll see a lot of LA caterers and Los Angeles food truck owners leaning on aluminum because it’s so easy to transport. But here’s the trade-off: it's a softer metal. That means it’s more likely to get dented or scratched up. It can also react with really acidic or alkaline foods, which can mess with the pan’s color and even the flavor of your food over time.

Understanding Pan Gauge

Once you’ve picked your material, you need to think about thickness, which we measure in gauge. It’s a bit counterintuitive, but just remember this: the lower the gauge number, the thicker and tougher the pan.

Think of it like buying a pair of work jeans. A lower number means heavier, more durable denim. It's the same idea here. A lower-gauge pan is built for the long haul.

- 22-Gauge: This is your standard, budget-friendly choice. It’s great for lighter-duty work, like holding toppings on a cold salad bar.

- 20-Gauge: A step up in durability. This is a solid all-rounder that’s much better at resisting dings and warping from high heat.

- 18-Gauge: This is the heavyweight champion. These pans are practically bulletproof and are what you want for the most punishing kitchen environments where they’ll be in constant, heavy rotation.

A standard 2.5-inch-deep full-size stainless pan holds about 8 to 9 quarts, while its 4-inch-deep cousin can handle around 12 to 14 quarts. In most professional kitchens, you’ll see gauges between 18 and 22, but the heavy-duty 18 and 20-gauge pans are really the backbone of any serious foodservice operation.

Unlocking More Potential with Essential Accessories

A full-size steam table pan is a workhorse on its own, but its real power comes alive when you pair it with the right accessories. These aren't just extra pieces of metal; they're what turn a simple pan into a finely-tuned system for holding, serving, and protecting your food in any busy Los Angeles kitchen.

The most basic accessory, and maybe the most important, is the lid. It’s your first line of defense for keeping food safe and tasting great, but not all lids are built the same. Picking the right one has a direct impact on what you hand over to your customers.

Lids, Lids, Lids: The Key to Control

Mastering your holding game really starts with understanding the different lids and what they’re designed to do on the line.

- Solid Lids: These are your go-to when you need to lock in every bit of heat and moisture. Think about holding a big batch of chili or marinara—a solid lid is what keeps it from drying out and losing temperature.

- Slotted Lids: Need to let off a little steam? That’s where a slotted lid comes in. It allows that extra moisture to escape, which is perfect for keeping fried chicken or french fries crispy instead of turning them soggy.

- Hinged Lids: For any self-service station or a fast-moving line, a hinged lid is a game-changer. It gives you quick, one-handed access without having to find a place to set down a hot, dripping lid. This makes your line faster and keeps things cleaner.

Using the right lid is one of the easiest ways to improve your food quality. It’s a small detail, but it makes a huge difference in texture and taste, ensuring the food you serve is just as good as it was coming out of the kitchen.

Specialized Inserts for Perfect Results

Beyond just lids, there's a whole world of specialized inserts that can solve common kitchen headaches and make your final product even better. These tools are designed to fit perfectly inside your pans, giving you new options without adding a bunch of steps to your workflow.

For instance, a busy Los Angeles food truck specializing in Mexican food can use a false bottom, which is a perforated insert that sits inside the pan. It lets all the grease from the ground beef or carnitas drain away, keeping the meat moist but not oily.

Another great tool is a perforated pan itself, which basically acts as a giant steamer basket. Just place it inside a solid pan with a bit of water at the bottom, and it’s perfect for steaming vegetables, seafood, or dumplings. These accessories aren't about cluttering up your kitchen; they’re about working smarter to serve better food.

Smart Cleaning and Maintenance for Longevity

Think of your restaurant equipment as a serious investment, because it is. That steam table pan full size you just bought is no different. Giving it the proper care is the real secret to making sure these kitchen workhorses last for years, saving you a ton of money and headaches in the cutthroat Los Angeles food scene.

The golden rule for stainless steel is simple: stay away from harsh chemicals and anything too abrasive. Cleaners packed with chlorides (like bleach), bromides, or iodides will eat away at the pan's protective layer. Over time, that leads straight to rust and pitting. Likewise, reaching for steel wool or heavy-duty scrapers will just create micro-scratches where bacteria can hide, making every future cleaning job that much harder.

Preventing Common Pan Problems

Even if you’re on top of your cleaning game, a few common issues can still pop up. Knowing what causes them is the best way to stop them before they start.

- Pitting: Ever seen tiny, isolated rust-like spots on your pans? That's pitting. It's usually caused by leaving salty or acidic foods in the pan for too long. To avoid it, make it a rule to empty and wash pans that held things like tomato sauce or brines as soon as you can.

- Heat Tint: This is that funky, rainbow-colored stain you see after a pan gets hit with high heat. It might look weird, but it's just a harmless oxidation layer. It won’t affect your food's safety or how the pan performs, and you can usually buff it out with a good stainless steel cleaner.

- Baked-On Food: We've all been there. For that stubborn, burnt-on mess, soaking is your absolute best friend. Fill the pan with a warm water and detergent solution, or make a paste with baking soda, and let it sit. This will loosen up the grime so you can scrub it away gently with a non-abrasive pad.

Protecting your investment goes way beyond just a good scrub. How you store your pans is just as critical. Stacking them carefully to prevent dents and deep scratches will dramatically extend their life, making sure they stay a reliable tool in your kitchen for the long haul.

Proper care is really a cornerstone of any successful kitchen. If you want to dive deeper into protecting all your equipment, check out our comprehensive guide on commercial kitchen equipment maintenance. Stick with these simple steps, and your steam table pans will keep on serving you and your customers reliably.

Getting Your Hands on Pans: Sourcing and Logistics for LA Restaurants

For any fast-paced Los Angeles kitchen, whether you're slinging tacos in Boyle Heights or plating fine dining in Beverly Hills, getting the right restaurant equipment is more than just a purchase—it’s a core part of your operational strategy. When it comes to something as fundamental as a steam table pan full size, your sourcing plan is what stands between a smooth service and a complete meltdown.

It all starts with a realistic look at your inventory. Before you even think about placing an order, you have to know your numbers. What does your menu demand? What's your volume on a slammed Friday night? How fast can your dish pit turn pans around? Running out of clean pans mid-service is a bottleneck that can bring an entire kitchen to its knees, and in a city where efficiency is everything, a reliable supply is a serious competitive advantage.

The Local Supplier Advantage

For Los Angeles restaurants, teaming up with a local supplier like us at LA Restaurant Equipment just makes sense. It’s an advantage that the big national online retailers simply can't touch, and you feel the difference most when it comes to speed and service.

- Lightning-Fast Shipping: Forget waiting a week for a truck to crawl across the country. When you order locally, pans often show up in just one to two business days. When a pan gets dropped and dented or you land a last-minute catering gig, that kind of speed is a game-changer.

- No-Hassle Returns and Warranties: Dealing with a warranty claim or a return is a thousand times easier when your supplier is just down the road. There's no complex long-distance shipping to figure out, just straightforward support from people in your own backyard.

- Real Local Know-How: A local supplier gets the LA scene. We understand the unique challenges you face, whether you're running a Los Angeles food truck, a ghost kitchen, or a full-service restaurant. We can offer advice that’s actually relevant to your business, not some generic script.

In a culinary pressure cooker like Los Angeles, downtime is a death sentence. Having a local equipment partner who can get you what you need, when you need it, isn't just a nice-to-have—it's your business continuity plan.

This isn't just a small-time need, either. The global market for steam table pans and similar gear is huge, estimated at over $1.2 billion and expected to keep growing. This reflects a simple truth: kitchens everywhere are expanding and need reliable equipment to function. If you're curious, you can explore more data on the growing steam table pans market.

At the end of the day, picking a supplier is about more than just the pan itself. It’s about finding a partner who gets that your success depends on having the right tools at the right time. For LA restaurants, going local provides the speed and expert support you need to not just survive, but thrive.

Your Questions, Answered

When you're running a busy kitchen, the little details can make a huge difference. Getting straight answers about something as fundamental as a steam table pan full size helps chefs and managers across Los Angeles make better buying decisions, solve problems on the spot, and keep the line moving.

Are All Full Size Steam Table Pans the Same Exact Size?

Pretty much, yes. The U.S. industry has a rock-solid standard size of roughly 20.75" x 12.75". You might see tiny, tiny differences between manufacturers, but they're all designed to be interchangeable. They’ll drop right into standard steam table wells and chafing dishes, no problem.

For almost any use case, you can mix and match brands without a second thought. The only time you’d ever need to break out a tape measure is if you have custom-fabricated restaurant equipment or very specific racks where a few millimeters might actually matter.

Can I Put a Steam Table Pan in the Oven?

Absolutely! High-quality stainless steel steam table pans are built like tanks and are completely oven-safe. This is one of their biggest advantages. You can cook, bake, roast, and reheat huge batches of food and then move the entire pan straight from the oven to the serving line.

Just remember the one golden rule: never put them directly on a stovetop burner. That kind of focused, intense heat can cause the metal to warp, which ruins the pan and leads to uneven cooking. For stovetop jobs, always grab the right tool, like a stock pot or a sauté pan.

What Is an Anti-Jam Steam Table Pan?

Anti-jam pans are a simple, brilliant solution to one of the most annoying problems in a kitchen. They have a subtle design tweak—usually a slightly flattened or reinforced corner—that makes all the difference.

This tiny change prevents a vacuum from forming when you stack the pans, so they don't get stuck together. When you’re in the middle of a rush and need a pan now, you can just grab one without a fight.

If you stack your pans for storage (and who doesn't?), investing in the anti-jam design is a no-brainer. It saves your crew a surprising amount of time and frustration, and it's one of those small details that just makes the whole operation run smoother.

Ready to stock your kitchen with reliable, high-quality steam table pans and other must-have gear? LA Restaurant Equipment offers warehouse-direct pricing and fast, local shipping all over Southern California. Check out our full selection online.