Walk into any commercial kitchen, and what’s the one piece of equipment you're guaranteed to see? The humble stainless kitchen prep table. It's the silent workhorse, the foundational stage where everything from meticulous vegetable prep to the final plating of an entrée happens. It’s far more than just a piece of furniture—it’s a critical tool built for the relentless pace of professional food service.

The Unsung Hero Of Your Commercial Kitchen

In the high-energy world of Los Angeles restaurants, every single item in your kitchen has to earn its keep. From a busy East LA taqueria serving classic Mexican food to a sleek downtown Los Angeles food truck, the stainless steel prep table is the one constant, the indispensable partner in every culinary creation. You could say it's a chef's most trusted companion, right after their favorite knife.

Think of it this way: a solid prep table is the foundation that supports your entire kitchen's workflow. If it fails, efficiency crumbles, and worse, food safety is put at risk. That's why picking the right table isn't just another purchase; it's a fundamental investment in your restaurant's success. To see how it fits into the bigger picture, take a look at our complete commercial kitchen equipment checklist.

Why Stainless Steel Reigns Supreme

There’s a good reason stainless steel became the undisputed king of the kitchen. It wasn’t a random choice—it was a practical one driven by factors that directly impact your bottom line and your reputation. The secret is its non-porous surface.

Unlike wood, which can trap bacteria deep in its grain, or painted metals that chip and rust, stainless steel is a smooth, impenetrable fortress. This quality makes it incredibly easy to clean and sanitize, which is non-negotiable for passing health inspections and keeping your customers safe.

The big shift to stainless steel really kicked into high gear in the mid-20th century, right as food safety laws started getting serious. Its ability to stand up to corrosion and handle constant, high-temperature cleaning made it the obvious choice for any modern kitchen.

This move was all about hygiene. Today's food safety guidelines still champion these surfaces because they stop bacteria from growing and let sanitizers do their job effectively. You can learn more about the history and growth of the stainless steel tables market size and its history to see just how essential it has become.

The Backbone of Kitchen Efficiency

Beyond being easy to clean, a stainless kitchen prep table is just plain tough. It’s built to withstand the daily abuse of a bustling kitchen—from the constant thud of knives and heavy pots to exposure to acidic foods like lemon juice and tomatoes.

This incredible resilience means it won’t warp, stain, or break down over time, giving you a reliable and consistent workspace for years. Whether you're slinging pies in a high-volume Los Angeles pizza joint or prepping in the tight quarters of a food truck, this piece of equipment is the unsung hero that keeps the whole show running.

Decoding Steel Grades And Gauges For Durability

Walking into the world of stainless kitchen prep tables, the spec sheet can feel like you're trying to read a foreign language. You see terms like "304 grade" or "16-gauge" tossed around, but what does that actually mean for your bustling Los Angeles kitchen? Getting a handle on these details is the secret to picking a table that won’t just last, but will become a reliable workhorse for years to come.

Think of it this way: you wouldn't slap regular car tires on a heavy-duty commercial truck that's hauling freight all day. It’s the same logic. The steel you choose for your prep table has to match the punishment it's going to take.

The Two Faces Of Stainless Steel: 304 Vs. 430

In most kitchens, you'll run into two main players: 304 and 430 grade stainless steel. They might look the same at first glance, but what’s going on inside them makes a world of difference in a tough restaurant environment.

Let's break down the two main contenders you’ll be choosing between.

Comparing 304 Vs. 430 Stainless Steel For Kitchen Use

| Feature | 304 Grade Stainless Steel | 430 Grade Stainless Steel |

|---|---|---|

| Corrosion Resistance | Excellent. The "gold standard." Highly resistant to rust, acids (citrus, vinegar), and salt. | Good. Can be prone to rust or pitting with prolonged exposure to acidic ingredients or harsh cleaners. |

| Durability & Makeup | Tougher and more durable due to its higher nickel and chromium content. The workhorse of the industry. | More affordable and still durable, but with less nickel, making it slightly more brittle over time. |

| Cost | Higher initial investment. | More budget-friendly. |

| Common Applications | Main prep stations, fish and meat cutting areas, dishwashing stations, or anywhere with lots of moisture and acidic foods. | Dry storage shelving, equipment stands, light-duty assembly stations, bakeries, or coffee shops. |

Ultimately, choosing the right grade is all about matching the metal to the mission. You don’t need to spring for 304 grade on a simple dry storage shelf. But trying to save a few bucks with 430 grade for your main prep line? That’s a recipe for rust and having to buy a replacement way sooner than you’d like.

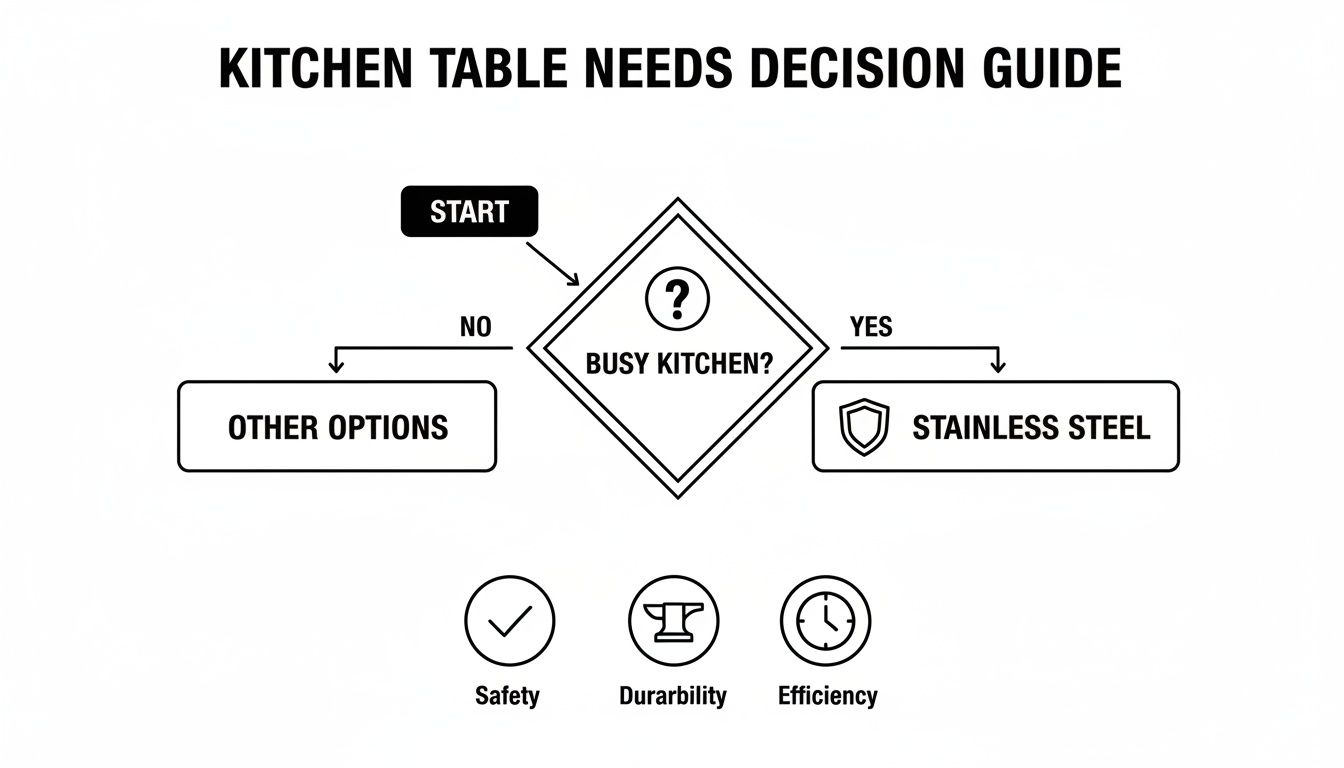

This quick decision guide can help you visualize where stainless steel really shines.

As you can see, for any high-traffic kitchen, stainless steel is really the only way to go for its unbeatable combination of safety, durability, and efficiency.

Understanding Steel Thickness: The Gauge Game

Right next to the grade, you'll see a number for the gauge. This tells you how thick the steel is. Here’s the tricky part that gets everyone: the lower the gauge number, the thicker and stronger the steel. It's a bit counterintuitive, but just remember that a smaller number means more metal.

A lower gauge table is your best friend for handling heavy equipment and the daily chaos of a busy kitchen without getting all dented and bowed.

It's a common mistake to think a higher gauge means higher quality. The reality is that a 14-gauge stainless kitchen prep table is significantly beefier and more durable than an 18-gauge one. For high-impact work, that extra thickness is a game-changer.

Here’s how the numbers usually break down in a commercial kitchen:

- 14-Gauge: This is the heavyweight champion. It’s the thickest, toughest option you’ll typically find, perfect for serious butcher tables or stations that have to hold heavy gear like a 60-quart mixer or a giant slicer.

- 16-Gauge: The sweet spot for most restaurants. 16-gauge offers a fantastic balance of serious durability and a reasonable price point. It’s the go-to for general prep tables in almost any setting, from pizzerias to food trucks.

- 18-Gauge: This is the lightest option that’s still considered commercial-grade. It's fine for lighter work—think a salad prep station or a surface for holding trays—but it will dent more easily than its lower-gauge siblings.

By decoding both the steel grade and its gauge, you're armed with the knowledge to make a smart buy. You'll be choosing a long-term asset for your kitchen, not a short-term headache.

Choosing The Right Size And Layout For Your Workflow

Okay, you've figured out the right grade and gauge of steel. Now for the fun part: picking the perfect size and setup for your kitchen. A stainless kitchen prep table isn't something you just drop into a room; it’s a critical piece of a much larger puzzle. The right one should feel like it was made for your workflow, not some clunky obstacle your staff has to dance around all day.

Think of it as designing a custom workstation. You have to consider the table's footprint, sure, but also how it fits into your kitchen's unique dance—whether that's a tight galley in a Los Angeles food truck or a big, open island in a bustling pizzeria. The goal is to make every single square inch count.

Mapping Out Your Space With Common Table Sizes

Before you even think about shopping, grab a tape measure. Seriously. Knowing your available space down to the inch is the most important first step. Commercial prep tables come in a whole range of standard sizes, and each one has its sweet spot.

Here are a few of the most popular dimensions and what they’re great for:

- 24" x 48" (4 feet long): This is your versatile workhorse. It’s perfect as a dedicated station for a single task, like building salads or plating desserts. In a smaller kitchen, this might be your main prep surface, and it won't eat up all your floor space.

- 30" x 60" (5 feet long): This is probably the most common size you'll see, and for good reason. It gives you a generous workspace—enough for two chefs to work together without bumping elbows during a rush. It’s big enough for serious prep but still fits nicely in most medium-sized kitchens.

- 30" x 72" (6 feet long): When you need some serious real estate for big projects, this is your go-to. Think rolling out huge batches of pizza dough, breaking down primal cuts of meat, or lining up a dozen sheet pans at once.

Quick tip: Don't forget about clearance. You need at least 36 inches of clear walkway around your tables. This lets your staff move safely and freely, especially when they're hustling with hot pans or heavy stock pots. Cramped aisles are a recipe for accidents and a total workflow killer.

Configurations That Boost Kitchen Efficiency

Beyond just length and width, the base of your stainless prep table plays a huge part in how useful it is. Do you need wide-open storage? Secure cabinets? A mix of both? What you choose here directly impacts your kitchen’s organization and speed.

A well-designed kitchen is the foundation of any successful restaurant. To dig deeper into optimizing your entire space, check out our guide on commercial kitchen layout and design for more pro tips.

Undershelves For Open Storage

The most common setup you'll find is a table with one or two open undershelves. This design is a classic for a reason—it gives you easy, see-it-all access to your most-used items.

- Pros: It’s perfect for stashing bulky equipment like stand mixers, big bins of flour, or stacks of pots and pans. The open design means you can grab what you need in a split second without fiddling with doors.

- Cons: Let's be honest, it can get messy if you don't stay on top of it. Everything on those shelves is also more exposed to dust and whatever else is on the kitchen floor.

Picture a busy Mexican food spot in LA. They might use an open-shelf table to keep big containers of salsa, guacamole, and prepped meats right at the line cook's fingertips.

Enclosed Bases And Drawers For Secure Storage

If you want a cleaner look and need to keep things more secure, an enclosed base with cabinet doors or built-in drawers is a fantastic option. This essentially turns your prep table into a dual-purpose storage beast.

- Pros: It keeps your supplies clean, organized, and hidden away. Drawers are a lifesaver for small tools, utensils, and spices, while the cabinets can hold less-used appliances or cleaning supplies.

- Cons: They do cost a bit more. And getting to your stuff means opening a door or drawer, which can be a fraction of a second slower than an open shelf during a crazy service.

A food truck is the perfect example of where this shines. Space is everything, so a table with a fully enclosed base and drawers maximizes every single inch. It keeps everything locked down, secure, and sanitary while you're on the move. When you match the table's size and layout to your kitchen's real-world needs, you're not just buying restaurant equipment—you're building a more efficient operation.

Essential Features And Smart Customizations

Once you’ve settled on the right size and steel grade, the real fun begins. The features and add-ons are what truly transform a simple sheet of stainless steel into the workhorse of your kitchen. These details aren't just bells and whistles; they're smart investments that will make your team faster, safer, and a whole lot more efficient.

Think of a basic prep table as a blank canvas. It's functional, sure, but the right customizations are like giving a chef their favorite set of specialized knives. Each feature is designed to solve a problem and streamline a specific task, saving you time and headaches down the line.

Protecting Your Workspace with Backsplashes

One of the most essential add-ons is a backsplash. This is a raised edge, usually 4 to 6 inches high, that runs along the back of the table. Its job is simple but absolutely critical: it keeps everything on the table and off your walls and floor.

A backsplash stops that stray diced onion from rolling away or prevents liquids from seeping into the hard-to-reach gap between the table and the wall. In a fast-paced L.A. kitchen, this is a lifesaver. You won’t have to pull heavy equipment out just to clean a small spill, and more importantly, it protects your walls from moisture and food splatter that can lead to grime and sanitation issues.

Any prep table that’s going against a wall needs a backsplash. Period. It’s a small detail that pays for itself over and over again in cleanliness and labor savings.

Getting Mobile with Casters

Another game-changer is adding casters (wheels) to your prep table. Suddenly, your static workstation becomes a mobile command center you can move wherever you need it most. This kind of flexibility is a massive plus in dynamic kitchens, like a ghost kitchen reconfiguring for a new brand or a Los Angeles food truck setting up for an event.

When you're looking at casters, you'll generally see two options:

- Locking Casters: This is the industry standard for a reason. They let you roll the table around for deep cleaning or layout changes, then lock it down so it’s rock-solid during heavy prep work.

- Non-Locking Casters: You'll see these less on primary prep stations. They’re better suited for light-duty utility carts that are always on the move.

The ability to easily roll a table out of the way for mopping is a huge sanitation win. No more missed spots in the corners of your kitchen.

Integrated Add-Ons for Specialized Workflows

To really dial in your table’s function, look at integrated features designed for specific jobs. An integrated sink, for instance, creates a self-contained station for washing and prepping produce, cutting down on the back-and-forth trips across the kitchen. It’s a simple way to boost productivity.

Likewise, an overhead shelf—sometimes called a double or triple overshelf—gives you valuable vertical storage without eating up more precious floor space. It's the perfect spot to keep spices, small tools, or plating dishes right where you need them. Browsing through the different prep tables available will show you just how many smart solutions there are, from built-in cutting boards to pot racks. Every customization is a chance to build a smarter, more organized kitchen.

Evaluating Load Capacity And Total Cost Of Ownership

Beyond the shiny surface and cool features, two real-world factors will make or break your investment in a stainless kitchen prep table: how much weight it can hold and what it really costs you over time. These aren't just numbers on a spec sheet. They're the difference between a safe, efficient kitchen and a long-term headache.

Ignoring load capacity is like buying a pickup truck without checking the tow rating—you’re setting yourself up for a serious breakdown right when you need it most.

Understanding Load Capacity Ratings

Load capacity tells you exactly how much weight a table can safely handle. This is absolutely critical if you plan on parking heavy restaurant equipment on it, like a beast of a commercial mixer, a meat slicer, or stacks of stockpots bubbling away. A table’s strength boils down to its steel gauge, leg design, and bracing.

Put too much weight on a flimsy table, and you’re asking for trouble. It can wobble, sag, or even collapse, creating a dangerous and expensive mess in the middle of a dinner rush.

Manufacturers will always give you a load capacity rating, which is the evenly distributed weight the table can support. A standard 18-gauge table might top out around 500 pounds, while a heavy-duty 14-gauge workhorse could easily handle over 1,000 pounds.

Think of it like building a bridge. You wouldn't use lightweight materials for a structure that has to support heavy traffic every day. If your prep table is pulling double duty as an equipment stand, investing in thicker, lower-gauge steel isn’t just a good idea—it’s a non-negotiable safety measure.

Thinking Beyond The Price Tag: Total Cost Of Ownership

The sticker price is just the beginning of the story. The smart way to look at this is by calculating the Total Cost of Ownership (TCO). This approach forces you to think about the entire life of the table, not just the day you buy it. You have to factor in durability, maintenance, and when you’ll inevitably have to replace it.

Total Cost of Ownership is the key to making a truly cost-effective decision. It shifts your focus from "What's the cheapest option now?" to "What's the smartest investment for the next decade?"

Let's break it down with a quick example:

- Table A (The "Bargain"): A lower-quality, 430-grade stainless table for $300. It’s not great with moisture, so in a busy kitchen, it starts to rust and warp. You'll be lucky to get 5 years out of it.

- Table B (The "Investment"): A high-quality, 304-grade stainless table for $450. This one is built for the grind. It can take a beating and lasts for 15 years with basic care.

Over a 15-year span, you’d have to buy Table A three times, costing you a total of $900. Table B, the one that seemed "more expensive" at first, still only costs you $450 over that same period. The investment in quality literally saves you 50% in the long run.

This is why you see so many pros go for the tougher stuff. Industry analyses show that a quality stainless prep table might cost 20–30% more upfront, but its 10–15 year service life demolishes the TCO of cheaper options. It means less money spent on replacements and fewer headaches from equipment downtime. If you're interested in the broader market, you can find more stainless steel table market trends on cognitivemarketresearch.com.

By looking at both load capacity and the total cost of ownership, you’re not just buying a piece of equipment. You're securing a lasting asset for your restaurant.

How To Clean And Maintain Your Stainless Steel Table

Think of your stainless kitchen prep table as a serious investment in your restaurant's future. To protect that investment and keep it a safe, clean surface for years on end, a solid cleaning routine is non-negotiable. Good habits prevent rust, keep the finish looking sharp, and are absolutely vital for passing health inspections, especially in a competitive town like Los Angeles.

The good news? Keeping stainless steel in top shape is actually pretty simple once your crew learns the right way to do it. It’s all about using the right stuff and, just as importantly, avoiding the wrong stuff. A little bit of daily attention goes a long, long way.

The Daily Cleaning Ritual

In the chaos of a busy kitchen, a simple, consistent approach always wins. This routine should become second nature at the end of every single shift to stop food residue from getting caked on.

- Clear and Scrape: First things first, get all the loose food scraps and junk off the tabletop. A soft plastic or rubber scraper is your friend here—anything harder will scratch the steel.

- Wash Thoroughly: Grab a mild detergent or a cleaner made specifically for stainless steel and mix it with warm water. Use a soft cloth or a non-abrasive sponge to wipe down the entire table.

- Rinse and Dry Completely: Splash some clean, warm water on the table to get rid of any soap. Now for the most important part: dry the surface completely with a microfiber cloth or paper towels. Skipping this step is how you get water spots and mineral buildup.

Here's a pro tip that gets missed all the time: always clean with the grain of the steel. Look closely and you'll see fine lines in the metal. Wiping in that direction helps keep the finish smooth and avoids creating tiny scratches where bacteria can set up shop.

What To Avoid At All Costs

Stainless steel is tough, but it's not invincible. It’s easy to get a false sense of security and grab the wrong cleaning tool, but some common products can permanently wreck your table’s protective layer, leading to rust and ugly pitting.

Make sure your team knows to keep these far, far away from your steel:

- Steel Wool or Abrasive Scrubbers: These will absolutely destroy the finish on your stainless kitchen prep table, leaving scratches that are perfect hiding spots for germs.

- Chlorine-Based Cleaners (Bleach): Chlorine is the arch-enemy of stainless steel. It’s highly corrosive and will cause rust spots and pitting before you know it.

- Harsh Chemicals and Oven Cleaners: Super aggressive cleaners can permanently stain or discolor the steel. Just don't do it.

Instead, stick to gentle, approved sanitizers. A simple mix of warm water and white vinegar can do an amazing job on tougher grime without causing any harm. For Los Angeles food trucks or restaurants serving Mexican food dealing with acidic ingredients like lime and tomato, this gentle approach is the secret to making your tables last. Follow these simple rules, and your prep table will stay a reliable, safe workhorse in your kitchen for years.

A Few Common Questions We Get

When you're outfitting a kitchen, a lot of questions come up. To help you feel confident in your choice, we’ve put together some quick answers to the most common things we’re asked about stainless prep tables here at our L.A. shop.

Can I Put Hot Pans Directly On The Table?

Yes, absolutely. Go for it. Stainless steel is built to handle the heat, which is exactly why it’s the go-to material for demanding commercial kitchens. You can pull a sizzling pan or a hot sheet tray right from the oven and set it on the surface without a second thought.

The only thing to be a little mindful of is extreme temperature shock over a long, long time—like putting a searing hot pan on a freezing cold table repeatedly. It could potentially cause a tiny bit of warping down the road, but for the day-in, day-out grind of a busy kitchen, you have nothing to worry about.

What Is The Best Way To Remove Scratches?

Look, minor scratches are just part of the deal in a working kitchen. They're a sign your equipment is being put to good use! But if you want to clean things up, you can often buff out light scuffs with a non-abrasive pad and a good stainless steel cleaner.

The key is to always rub gently in the same direction as the steel’s grain, not against it. For anything deeper, you might need a special scratch removal kit, but honestly, most chefs just see those little marks as badges of honor.

Is It Better To Get a Table With Wheels or Without?

This really comes down to how you work and how you clean. There’s no single right answer, just the right answer for your kitchen.

- Tables with wheels (casters) are all about flexibility. You can rearrange your line on the fly or easily roll the table out of the way for a thorough deep clean. For sanitation, that’s a huge win.

- Tables with stationary legs offer pure, unshakeable stability. If the table is going to hold a heavy mixer or be a station for heavy-duty butchering, stationary legs give you a rock-solid base that won’t budge.

In a fast-paced environment or for spots where easy cleaning is a top priority (like in a food truck), tables with locking casters are a fantastic choice and what we recommend most often.

Pro Tip: You can get the best of both worlds. A lot of chefs opt for a table with two locking casters and two stationary legs. It gives you a great mix of solid stability and just enough mobility to make cleaning easy.

How Do I Choose Between An Undershelf And An Enclosed Base?

This is a classic trade-off between instant access and enhanced cleanliness. An open undershelf is your best friend for storing bulky items you need to grab in a flash—think big stockpots, Cambro containers, or countertop appliances. It’s all about grab-and-go efficiency.

On the other hand, an enclosed cabinet base is perfect for things you want to keep protected from the daily splashes and dust of a busy kitchen. It's a great spot for delicate tools, clean linens, or equipment you don't use every single day. For many Los Angeles restaurants where space is at a premium, an enclosed base is a smart way to get extra, tidy storage.

Ready to find the perfect workhorse for your kitchen? At LA Restaurant Equipment, we offer a wide selection of new, warranty-backed stainless steel prep tables to fit any workflow and budget. Explore our collection and get fast, free shipping across Southern California. https://larestaurantequipment.com