A good commercial kitchen equipment checklist isn't just a shopping list. Think of it as your strategic game plan for any Los Angeles restaurant, from a classic Los Angeles Pizza parlor to a bustling Mexican Food spot, or even one of the many iconic Los Angeles Food Trucks. It’s how you organize everything you buy around your actual workflow—cooking, refrigeration, prep, warewashing, and storage—to make sure your kitchen runs like a well-oiled machine and passes health codes from the get-go.

Laying Out Your Kitchen Blueprint

Before you even think about buying a single stainless steel table or a commercial range, you need a strategy. I can't stress this enough: creating a detailed plan is the single most important part of outfitting a new kitchen or renovating an old one. A solid blueprint saves you from making expensive mistakes, guarantees a smooth workflow for your crew, and helps you sail through those tough Los Angeles County health codes.

Stop thinking about your kitchen as just a room full of appliances. Instead, see it as a series of connected stations. Each station has a job to do, and the restaurant equipment inside it has to support that job perfectly. This way of thinking works whether you're designing a huge kitchen for a new Mexican food restaurant downtown or trying to squeeze every last inch of utility out of one of the famous Los Angeles food trucks destined for Silver Lake.

The Core Kitchen Stations

No matter the cuisine, every commercial kitchen is built around a few fundamental zones. When you organize your checklist by these stations, you’re setting yourself up for a logical and efficient space.

To get a clearer picture, here's a quick look at how these stations apply to a couple of popular Los Angeles food concepts.

Essential Kitchen Stations At-a-Glance

| Kitchen Station | Core Function | Example for a Pizza Shop | Example for a Food Truck |

|---|---|---|---|

| Cooking & Baking | Where the menu comes to life through heat. | Deck ovens, dough sheeter, commercial mixer | Griddle/flattop, deep fryer, panini press |

| Refrigeration | Preserving ingredients and ensuring food safety. | Walk-in cooler, pizza prep table, low-boy refrigerator | Undercounter refrigerators, reach-in freezer |

| Food Preparation | Washing, chopping, and mixing raw ingredients. | Stainless steel prep tables, sinks, dough prep area | Compact prep counters, food processors |

| Warewashing | Cleaning and sanitizing all dishes and tools. | High-temp conveyor dishwasher, 3-compartment sink | Compact 3-compartment sink, drainboards |

| Service & Holding | Keeping finished food at safe, ready-to-serve temps. | Heated holding cabinet, pizza display warmer | Steam table, heat lamps, insulated bags |

Structuring your plan this way from the start makes the whole process, from purchasing to installation, so much smoother.

This isn't just a local trend; it's a global standard that's fueling a massive industry. The commercial kitchen appliances market hit a value of $98.34 billion in 2024 and is only expected to climb. North America is leading the charge, which shows just how high the standards are here. You can dig into more data on the commercial kitchen equipment market to see where things are headed.

The whole process really boils down to three key phases.

This simple flow—plan, purchase, install—really drives home the importance of starting with a rock-solid blueprint before you spend a dime. If you skip the planning, buying becomes a guessing game, and installation can create workflow nightmares that will frustrate your team and slow down service. Your checklist is the map that keeps every step on track.

Equipping Your Cooking and Prep Stations

The cooking line is the heart of your restaurant. It's the engine where your menu truly comes to life. Building out this area means you need to think less like a shopper and more like a chef orchestrating a chaotic dinner rush. Every single piece of restaurant equipment has to earn its keep, directly contributing to the speed, quality, and consistency of your dishes.

Your menu is the only blueprint that matters here. It dictates every major equipment choice, from the type of oven you need to how many burners your range should have. A piece of gear that's absolutely essential for one concept might be a complete waste of precious space for another—a critical mistake you can't afford to make in a cramped Los Angeles kitchen.

Matching Your Cook Line to Your Concept

Let's break this down with a couple of real-world L.A. scenarios.

Say you're opening a spot serving authentic Mexican Food. Your checklist immediately needs to focus on high-volume, high-heat gear. A six-burner range with a built-in griddle is a great start, letting you juggle pots of simmering carnitas while searing carne asada. But if you want truly authentic tortillas, a separate countertop plancha gives you dedicated space and the precise temperature control you need to nail them every time.

Now, picture a Los Angeles pizza joint. The oven is everything. It’s the star of the show, and your choice has massive implications for your final product and kitchen workflow.

- Deck Ovens: These are the classics for a reason, producing an artisanal, crisp crust. They take more skill to master but the flavor payoff is incredible.

- Conveyor Ovens: If you’re slinging pies fast-casual style, this is your machine. It’s all about high-volume, consistent output where speed is the name of the game.

- Wood-Fired Ovens: For that authentic Neapolitan-style pizza, nothing else comes close. It delivers a distinct smoky flavor but demands specialized ventilation and a skilled pizzaiolo who knows how to work it.

The right decision comes down to your brand, your price point, and the experience you want to give your customers.

Building Your Cooking Equipment Checklist

Beyond the big, concept-specific items, every kitchen needs a core set of cooking appliances. It's best to break this part of your checklist down by function to make sure you don't miss anything. Think about your daily prep load and what your busiest service hours will look like to get the size and capacity right.

Your foundational cooking equipment should include:

- Commercial Range: The absolute workhorse of any kitchen. You'll need to choose between gas and electric and decide on the number of burners your menu requires.

- Oven: Will you need a convection oven for perfectly even baking, a standard oven, or a more versatile combination unit?

- Fryer: Look at your menu's fried items to figure out the capacity you'll need. A small cafe might get by with a single-basket fryer, but a busy spot will definitely need a double-basket model.

- Griddle or Charbroiler: Essential for everything from pancakes to burgers and steaks. The size should be based on how many you expect to sell during your peak rush.

Here’s a critical piece of advice for LA operators: Always, always check your equipment's specs against your ventilation hood's capacity. A powerful new range is useless—and flat-out dangerous—if your hood can't handle the heat, smoke, and grease it pumps out. This is a common and incredibly costly oversight.

The demand for this kind of gear is booming right alongside the food service industry. In fact, the commercial cooking equipment market is projected to hit $26.5 billion by 2035, a huge leap driven by our collective craving for quick, delicious food. This growth just highlights how important it is to invest in reliable, specialized appliances. You can dive deeper into commercial cooking equipment market trends to see why quality really matters.

Don't Forget the Prep Equipment

An efficient cooking line is only as good as the prep station that feeds it. This part of your checklist is just as important, because this is the gear that allows your team to work quickly and consistently before the first ticket ever prints. A well-equipped prep area is where you gain a serious edge in kitchen efficiency.

Your essential prep list should have:

- Food Processors: For chopping, slicing, and dicing mountains of vegetables in minutes.

- Industrial Mixers: A big floor mixer is non-negotiable for a pizzeria or bakery that needs to produce large batches of dough.

- Slicers: Crucial for delis, sandwich shops, or any concept that needs uniform slices of meat and cheese, fast.

- Prep Tables: You can never have enough stainless steel work surfaces. Measure your space carefully and squeeze in as much as you can possibly fit.

By thoughtfully selecting both your cooking and prep gear, you create a seamless flow where your team can execute your menu flawlessly, even when you're completely slammed. This turns a simple list of equipment into a true recipe for success.

Mastering Your Refrigeration and Storage

Once you've dealt with the heat of the cooking line, it's time to think about the chill. Your refrigeration and storage systems are the unsung heroes that keep your food safe, your inventory tight, and your bottom line healthy. Getting this part of your restaurant equipment right is absolutely non-negotiable.

Proper cold storage is what stands between you and costly spoilage, keeping ingredients fresh and ensuring you're always ready for service. It’s also key to satisfying those strict Los Angeles County health codes. From massive walk-in coolers to nimble under-counter units, every piece has a purpose. The goal is to perfectly match the equipment to your menu, your kitchen's footprint, and your daily workflow.

Choosing Your Core Refrigeration Units

Most kitchens I've worked with need a mix of different refrigeration units to keep things running smoothly. Each type plays a specific role.

Here's a breakdown of your main options:

- Walk-In Coolers & Freezers: These are the heavy lifters for bulk storage. A Los Angeles pizza place, for example, is going to need a spacious walk-in just to hold all its cheese, tubs of sauce, and dough trays.

- Reach-In Refrigerators & Freezers: You'll want these positioned near your prep and cooking lines. They give your staff quick access to ingredients they'll be grabbing all day long.

- Undercounter Refrigerators: These little guys are fantastic for maximizing space. Tucked under a workstation, they keep essential items exactly where they're needed.

- Prep Tables: By combining a refrigerated base with a workspace on top, these become the heart of any sandwich shop, pizzeria, or salad station. They are true workhorses.

One thing I always tell clients: think about lifespan. Commercial refrigeration units are built to last 10-15 years, but that's only if you keep up with maintenance. Neglect them, and you’re asking for a kitchen emergency you simply can't afford.

A Real-World Scenario: Los Angeles Food Trucks

Let's think about one of the classic Los Angeles food trucks. Space is everything. Every single inch counts. A walk-in is obviously out of the question, but a smart combination of reach-in and undercounter units is the perfect play.

An upright reach-in freezer can hold your bulk items like fries and frozen proteins. Then, you can tuck a series of energy-efficient undercounter fridges right into the prep and service line. This setup puts fresh ingredients for Mexican food like tacos or burgers within arm's reach, which dramatically speeds up assembly and service times—a huge win during that chaotic lunch rush.

It’s this kind of strategic thinking that keeps the workflow tight and efficient. You can explore a wide variety of commercial refrigerators suitable for any space to find the models that will fit your specific needs, big or small.

Organizing Your Dry and Cold Storage

Once you’ve picked your main units, how you organize the space inside them is just as critical. The right shelving does more than just look neat—it prevents cross-contamination, makes inventory a breeze, and helps your team follow the "First-In, First-Out" (FIFO) rule without even thinking about it.

You really have two main choices here:

| Shelving Type | Key Advantages | Best For |

|---|---|---|

| Stainless Steel | Incredibly durable, a snap to clean, and holds heavy loads without batting an eye. | The perfect choice for dry storage areas holding heavy sacks of flour or sugar. |

| Polymer/Coated | Resists corrosion, making it ideal for the damp environment of a walk-in cooler. It's often modular and easy to adjust. | This is your go-to for inside walk-in refrigerators and freezers to stop rust in its tracks. |

Remember, proper shelving isn't just about tidiness; it's a food safety requirement. It keeps products off the floor, promotes proper air circulation in your coolers, and makes daily cleaning so much easier. A well-organized storage system, both cold and dry, is the backbone of any efficient kitchen. It cuts down on waste and ensures your team can always find what they need, right when they need it.

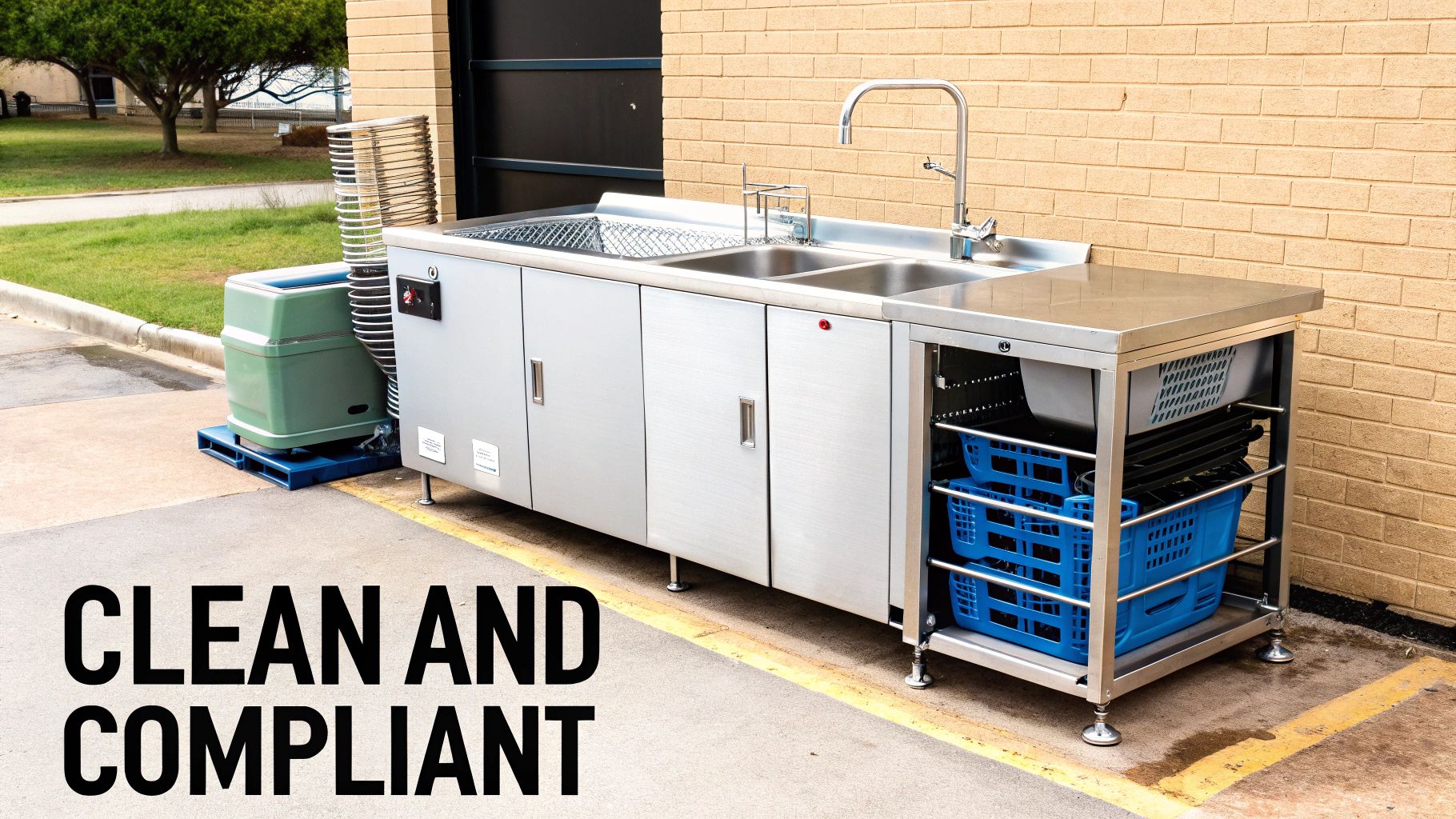

Assembling Your Warewashing and Sanitation System

Sure, the cooking line gets all the attention, but your warewashing and sanitation station is the real unsung hero of any successful restaurant. This is the engine room that keeps your operation clean, compliant, and ready for every single service.

If this station goes down, your entire business can grind to a halt. That’s why every single piece of restaurant equipment for this area is non-negotiable and absolutely critical to get right.

An efficient setup isn’t just about having the right machines; it's about creating a smooth, one-way workflow. This is key to preventing cross-contamination and keeping the Los Angeles County Department of Public Health happy. And it all begins with the most fundamental piece of the puzzle: the three-compartment sink.

The Cornerstone: Your Three-Compartment Sink

Let's be clear: you cannot legally operate a commercial kitchen without a proper three-compartment sink. It's not optional. Each basin serves a distinct, mandated purpose that your team needs to follow to the letter.

It's a simple but rigid process—wash, rinse, sanitize.

- Wash: The first sink is for hot, soapy water. This is where you scrub off all the grease and food bits.

- Rinse: The middle compartment is for clean, hot water to wash away all the soap from the first step.

- Sanitize: The last sink holds a chemical sanitizing solution, mixed to the right concentration and temperature, to eliminate any lingering bacteria.

To make this system work properly, you’ll also need drainboards on both sides. One side is for staging dirty dishes waiting to be washed, and the other is for clean, sanitized items to air dry. Never, ever towel-dry your wares. It can reintroduce the very germs you just worked so hard to get rid of.

Choosing the Right Commercial Dishwasher

While the three-compartment sink is a must for large pots, pans, and utensils, a commercial dishwasher is your ticket to handling high volumes of plates, glasses, and flatware efficiently. The right machine for you depends entirely on your kitchen’s size and how many covers you do.

- Door-Type Machines: These are the workhorses for most busy restaurants. They can blast through a full rack of dishes in about 90-120 seconds and often use high-temperature cycles to sanitize, which means you don't need chemical sanitizers for those items.

- Undercounter Models: Ideal for a small cafe, bar, or one of L.A.'s many Los Angeles food trucks where every inch of space counts. They look a lot like residential dishwashers but are built for commercial-grade speed and abuse.

- Conveyor Dishwashers: This is the big league. Think hotels, large-scale catering operations, or institutions. These machines can power through hundreds of racks per hour without breaking a sweat.

Here’s a crucial pro-tip on placement: Your warewashing station needs to be a one-way street. Dirty dishes come in on one side, move through the washing and sanitizing process, and exit on the other side, clean and ready for service. The clean and dirty paths should never cross. This workflow is non-negotiable for preventing cross-contamination.

Investing in modern, efficient equipment like this is a smart move. The global commercial kitchen equipment market hit about $8.57 billion in 2021 and is expected to keep growing, with North America leading the charge. This just goes to show how vital it is to put your money into reliable, high-performance appliances. You can dive deeper into the numbers by checking out the full commercial kitchen equipment market report.

Essential Sanitation Supporting Gear

A great warewashing station is more than just a sink and a dishwasher. To run a truly clean and compliant operation, you need a few other key components. Think of them as the supporting cast that makes the whole system work.

Make sure your checklist also includes:

- Dedicated Handwashing Sinks: Health codes demand these. You need them in both the kitchen and prep areas, and they must be completely separate from your warewashing or food prep sinks.

- Grease Trap: This is an absolute necessity in Los Angeles. It prevents grease from wrecking the municipal sewer lines. Make sure it's sized correctly for your output and serviced on a regular schedule.

- Chemical Storage: You'll need a designated, secure spot to store all your cleaning and sanitizing chemicals, safely away from any food.

- Drying Racks: You can never have enough. Get plenty of shelving or mobile racks for air-drying everything from sheet pans to cambros.

Sourcing and Installing Your Kitchen Equipment in Los Angeles

Alright, you’ve got your commercial kitchen equipment checklist finalized. That’s a huge milestone. Now comes the real work: turning that list into a real, breathing, functional LA kitchen. This is where you’ll make the tough calls on purchasing, financing, and installation that can make or break your budget and your grand opening timeline.

In a market as fierce as Los Angeles, sourcing your gear smartly is just as critical as choosing the right range or walk-in. This is where the rubber really meets the road.

One of the first big decisions you’ll have to wrestle with is whether to buy new or used restaurant equipment. I get it—the lower price tag on used gear is seriously tempting, especially if you're launching a food truck or a lean pop-up. But it’s a gamble. You’re often dealing with no warranty, a higher risk of breakdowns, and a totally unknown service history.

On the flip side, buying new gets you full warranty protection, the latest in energy-saving tech, and most importantly, peace of mind.

New vs Used Equipment for LA Operators

For restaurant owners here in Los Angeles, the choice between new and used gear isn't just about the initial price. It's a strategic decision that balances upfront savings against long-term operational headaches. A new Los Angeles pizza place in Silver Lake might splurge on a brand-new deck oven for its reliability and warranty but save money by sourcing used stainless steel prep tables.

Here’s a breakdown to help you weigh your options:

| Decision Factor | Benefits of New Equipment | Benefits of Used Equipment | Key LA Consideration |

|---|---|---|---|

| Warranty & Support | Full manufacturer warranty covers parts and labor, which is a lifesaver. | Usually sold "as-is," meaning every repair bill comes straight out of your pocket. | In this city, downtime is a killer. A warranty is your safety net against lost revenue. |

| Compliance & Safety | Guaranteed to meet current NSF, UL, and local health and safety standards right out of the box. | Might not meet the latest codes, putting you at risk of failing a surprise health inspection. | LA has some of the toughest codes in the country. New gear ensures you pass the first time. |

| Energy Efficiency | Modern units are often ENERGY STAR® rated, which can dramatically lower your utility bills. | Older models are almost always less efficient, leading to higher operating costs every single month. | With California's steep energy prices, efficiency isn't a luxury—it's a direct boost to your bottom line. |

| Initial Cost | Requires a higher upfront investment, no doubt about it. | The lower initial price frees up precious capital for other startup needs like inventory or marketing. | Financing options for new equipment are widely available and can make the upfront cost much more manageable. |

Ultimately, a hybrid approach often works best. Identify the mission-critical items where reliability is non-negotiable (like your primary cooking line and refrigeration) and consider buying those new. For everything else, high-quality used equipment can be a smart, budget-friendly choice.

Navigating Local Compliance and Installation

Once you’ve picked your equipment, your next big hurdle is navigating the maze of Los Angeles’s specific compliance rules. This isn’t just about the health department; you also have to satisfy the LA Department of Building and Safety (LADBS) and the local fire department.

Every single piece of equipment needs the right certifications. Keep an eye out for these two logos:

- NSF (National Sanitation Foundation): This seal means the equipment is designed for food safety—it's easy to clean, sanitize, and won't harbor bacteria. It's a non-negotiable for health inspectors.

- UL (Underwriters Laboratories): This mark certifies that the equipment meets safety standards for electrical and gas components. It’s crucial for preventing fires and passing inspections.

Installation is another area where you absolutely cannot cut corners. Any equipment that hooks up to gas, plumbing, or high-voltage electricity must be installed by a licensed professional. Trying to DIY this is not only incredibly dangerous, but it will also instantly void your warranty and get you shut down by an inspector. This is especially true for your ventilation hood and fire suppression system—these are life-safety systems that legally require certified installation.

A common mistake I see all the time is bad scheduling. Don't have your massive walk-in cooler delivered before the floors are even finished or your range installed before the gas lines are approved. You have to coordinate with your general contractor to create a delivery and installation schedule that actually matches the construction timeline. It’ll save you a world of chaos and costly delays.

Financing Your Kitchen Equipment

Let’s be real: outfitting a commercial kitchen is a massive investment. The good news is that Southern California businesses have a lot of financing options that make getting new, reliable restaurant equipment much more accessible without draining your startup capital.

Financing lets you get the high-quality gear you need now while paying for it over time with predictable monthly payments. This is almost always a smarter move than buying cheap, used equipment that could cost you more in repairs and downtime in the long run.

By financing new equipment, you can keep more cash on hand for other essentials like payroll, your first big inventory order, and marketing. To understand how equipment fits into the grand scheme of things, it’s worth checking out a complete restaurant startup costs breakdown.

Whether you’re serving Mexican food in East LA or running one of the premier Los Angeles food trucks in the Valley, managing your capital effectively from day one is the key to surviving and thriving here.

Common Questions About Kitchen Equipment

Outfitting a commercial kitchen brings up a ton of questions, and getting straight answers is the key to making smart buys and sidestepping common headaches. Here are some of the questions we hear most often from fellow Los Angeles operators, along with some practical advice from our years in the business.

How Do I Determine the Right Size and Capacity for My Cooking Equipment?

This one always comes back to your menu and your busiest hour. A high-volume Mexican food spot in East LA cranking out street food all day needs a much beefier griddle than a small cafe that only offers breakfast burritos until 11 a.m.

Your range, fryer, and ovens have to keep up when you're slammed. If they can't, you've created a bottleneck that slows down the whole line and costs you sales during the rush. A classic rookie mistake is buying gear that's too small, plain and simple.

But here's the real kicker: before anything else, measure your physical space and, most importantly, the capacity of your ventilation hood. All the cooking power in the world is useless—and a serious fire hazard—if your hood can't pull the heat and grease you're producing. Seriously, talk to a kitchen designer to map out your workflow and match your equipment to what you actually plan to sell.

What Are the Most Important Energy Efficiency Ratings to Look For?

In California, you want to see that ENERGY STAR® logo. It's the gold standard. Equipment with this certification can be anywhere from 10% to 70% more energy and water-efficient than standard models. That’s real money you'll save on your utility bills, month after month.

For gas appliances, a lower BTU rating on a high-output unit is a good sign—it means the equipment is doing more with less fuel. When it comes to refrigeration, look for modern, eco-friendly refrigerants like R290, which are much better for the environment.

It might cost a bit more upfront to go with high-efficiency models, but you'll make it back in operational savings over the life of the unit. Plus, you can often qualify for local energy rebates here in LA, which helps close that initial price gap.

Thinking about how to handle those upfront costs is a smart move. For many LA businesses, exploring the options for financing restaurant equipment makes it possible to get top-tier, efficient gear without wiping out your startup cash.

Do I Need Professional Installation for All My Kitchen Equipment?

One hundred percent yes—for anything that hooks up to a gas line, high-voltage electricity, or your plumbing. This isn't just a friendly suggestion; it’s a non-negotiable requirement for your permits, your insurance, and your safety. Botch the installation, and you’re looking at a major fire hazard and an instantly voided warranty.

Some systems are even more strict. For things like walk-in coolers, ventilation hoods, and fire suppression systems, professional installation is mandatory to pass health and fire inspections in Los Angeles County. Trying to cut corners here is just asking for failed inspections, expensive delays, and a whole lot of risk you don't need.

Should I Repair or Replace My Old Equipment?

Ah, the age-old question for any established restaurant. We live by the 50% rule: if a repair is going to cost you more than half the price of a brand-new unit, it's almost always time to replace it.

Don't forget to consider the age of the equipment, too. Most cooking gear has a lifespan of about 8-12 years, and refrigeration usually lasts 10-15 years. If your machine is getting up there in age and breaking down all the time, you're just throwing good money after bad.

Swapping out old equipment also means you get better energy efficiency, new features, and a fresh warranty to protect you from surprise repair bills. Trust me, patching up an old, unreliable machine will cost you far more in the long run through downtime, lost sales, and those never-ending service calls.

At LA Restaurant Equipment, we specialize in new, warranty-backed commercial kitchen equipment at warehouse-direct prices, so you can avoid the gamble of used gear. Check out our full inventory online at https://larestaurantequipment.com and get the reliable, efficient equipment your Los Angeles business deserves.