Let’s be honest, that chaotic chest freezer in the back isn't just an eyesore—it's actively costing you money. It’s a direct hit to your restaurant's bottom line.

Every minute a cook spends digging through an icy abyss for that one specific ingredient is a minute you're paying for. In a fast-paced market like Los Angeles, that kind of inefficiency is a killer. A disorganized freezer is a serious bottleneck in your kitchen's workflow, whether you're running one of the top Los Angeles Pizza places or a popular Mexican Food truck.

Think of it as a hidden tax on your entire operation. The mess directly eats away at your two most critical resources: your team's time and your valuable inventory. When ingredients are impossible to find, service grinds to a halt and ticket times creep up. The right restaurant equipment, organized properly, is the backbone of a successful LA eatery.

Why a Disorganized Freezer Hurts Your Bottom Line

The financial drain from a messy freezer goes way beyond wasted payroll. It kicks off a nasty cycle of loss that silently chips away at your margins. A busy Los Angeles food truck, for example, can't afford a five-minute delay during the lunch rush because someone can't find the prepped carnitas.

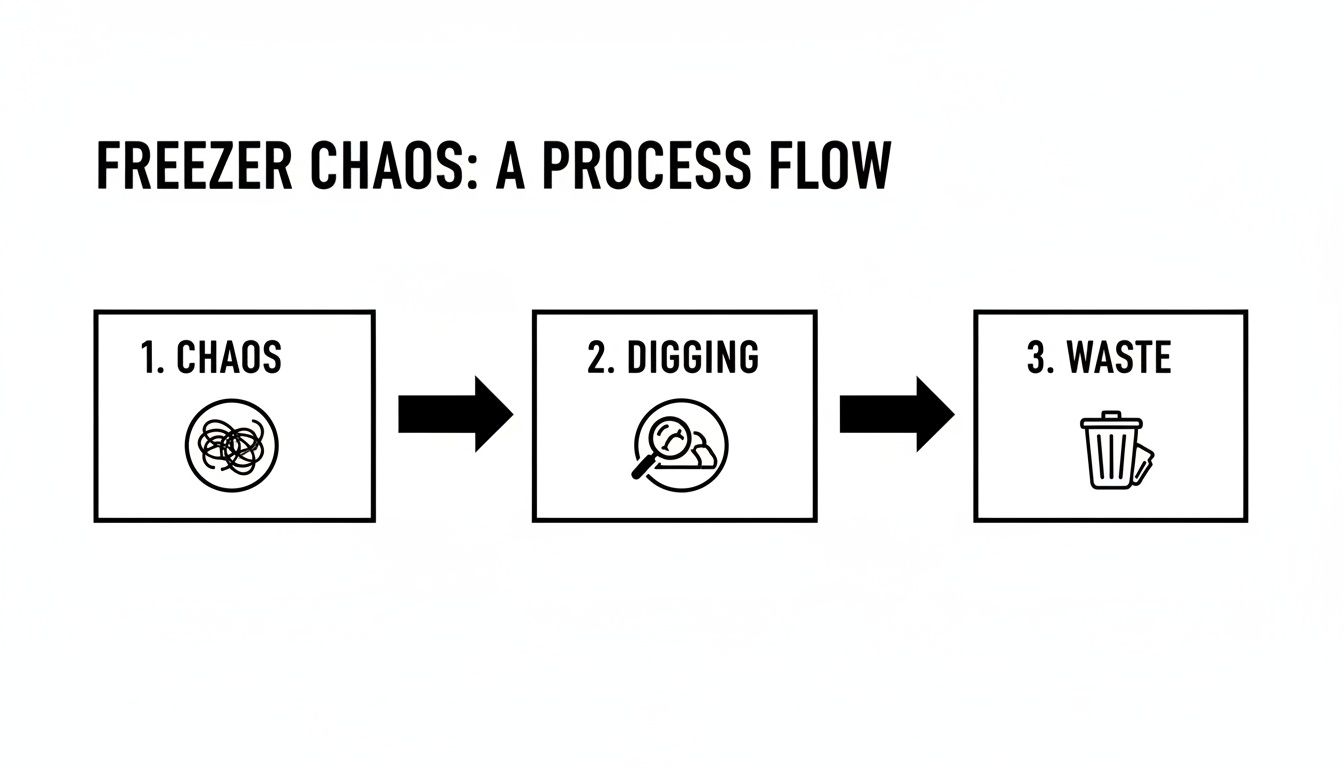

Here’s exactly how that freezer chaos is costing you money:

- Food Waste: Items get buried at the bottom, forgotten until they’re freezer-burned and completely unusable. Industry reports show that food waste can make up 10% of a restaurant's total food purchasing costs. Your freezer is ground zero for this problem.

- Over-Purchasing: If you can't see what you have, you’ll inevitably buy duplicates. This ties up your cash in stock you don't need and makes it more likely the older stuff will get pushed to the back and eventually spoil.

- Reduced Energy Efficiency: Every time that lid stays open for a prolonged search, cold air pours out. The freezer's compressor has to work overtime to get back to the right temperature, which means higher electricity bills for you. This is a common issue with older restaurant equipment.

A well-organized freezer isn’t about being neat and tidy; it’s a core piece of lean inventory management. It guarantees you use what you buy, smooths out kitchen operations, and protects the quality of your food.

Building a Foundation for Kitchen Efficiency

This guide is for the busy operators of Los Angeles restaurants, from food trucks to brick-and-mortar spots, who know that small, smart changes can lead to huge wins. We're going to show you how to turn that frozen pit into a streamlined, money-saving system.

This is about more than just cleaning up. It’s about creating a predictable workflow that anyone on your staff—from a seasoned chef to a brand-new line cook—can understand in a second. Think of it as drawing a map for your frozen goods, with dedicated zones for proteins, vegetables, sauces, and prepped items, whether you're running a Mexican Food concept or a Los Angeles Pizza joint.

By putting these strategies into practice, you're not just organizing a freezer. You're building a smarter, more resilient, and more profitable kitchen.

Designing Your Freezer Layout for Maximum Efficiency

Let's be honest, a well-organized freezer doesn't happen by accident. It starts with a smart plan, not just good intentions. Before you even think about moving a single box, you need to map out your freezer's interior to match the unique rhythm of your kitchen. Don't just see it as a cold storage box; think of it as a vital piece of restaurant equipment in your kitchen's entire operational flow.

For any busy Los Angeles food truck or restaurant, this means getting real about your menu's velocity. What ingredients are you grabbing constantly? Which items get used together? Your freezer layout should be a direct reflection of this reality, with your fastest-moving products in the easiest-to-reach spots.

Plan Your Zones Before You Buy Bins

Hold off on buying any accessories for a minute. First, grab a piece of paper and sketch out a rough map of your freezer. The key is to divide the entire space into logical zones based on food categories. This is the same thinking that goes into any efficient commercial kitchen layout design—every inch has a purpose. A typical restaurant will create zones for different proteins, vegetables, and prepped items.

For instance, a Mexican Food spot in LA might set things up like this:

- Zone 1 (Left Side): All the raw proteins—carne asada, carnitas, chicken—kept in dedicated, sealed containers. No chances of cross-contamination.

- Zone 2 (Middle): Bulk items like vegetables, huge bags of tortillas, and frozen house-made salsas.

- Zone 3 (Right Side): Pre-portioned sauces, stocks, and specialty ingredients like that amazing house-made chorizo.

This simple zoning strategy is what stands between you and pure freezer chaos. Without a system, you get a costly cycle of digging, wasting time, and ultimately, throwing out spoiled food.

As you can see, disorganization isn't just an inconvenience; it's a direct line to lost profit. A zoned layout breaks this cycle by giving your entire staff a predictable, easy-to-navigate system.

Here’s a sample layout to help you visualize how to zone a commercial chest freezer for peak efficiency and food safety.

Sample Zoning Plan for a Commercial Chest Freezer

| Zone | Contents | Organizational Tool | Rationale |

|---|---|---|---|

| Top Left (High Access) | High-turnover prepped items (e.g., portioned sauces, burger patties, soup bases) | Stackable, clear, shallow bins | Easiest to grab during service. Clear bins allow for quick identification without digging. |

| Bottom Left (Raw Meats) | Vacuum-sealed raw proteins (beef, chicken, pork) | Color-coded, solid, deep bins | Keeps raw meats at the bottom to prevent drips and cross-contamination. Color-coding (e.g., red for beef, yellow for poultry) speeds up retrieval and prevents mix-ups. |

| Middle (Vegetables & Fruits) | Bulk frozen vegetables, fruit purees, fries | Large wire baskets or open-top bins | Allows air to circulate and makes it easy to see inventory levels of bulky items at a glance. |

| Top Right (High Access) | Breads, tortillas, and baked goods | Labeled, lightweight bins or bags | Keeps delicate items from being crushed and provides quick access for items used daily. |

| Bottom Right (Seafood) | Vacuum-sealed fish and shellfish | Dedicated, lidded, non-porous containers | Isolates seafood to prevent odor transfer and cross-contamination with other proteins. Lids provide an extra layer of protection. |

This table is just a starting point, of course. The best system is one that’s customized to fit your menu and workflow.

Choose Tools That Fit Your Plan

Now that you've got your zones mapped out, it's time to pick the right tools for the job. The trick is to find containers that fit your freezer's dimensions perfectly. Get out a tape measure and write down your freezer’s length, width, and depth before you buy a single thing.

You’ll want to look for commercial-grade, stackable bins that are square or rectangular. Round containers are a rookie mistake—they create "dead air" space between them, and that's a luxury no commercial kitchen can afford. Heavy-duty wire baskets or adjustable dividers are also fantastic for creating permanent, sturdy boundaries between your zones. Investing a little upfront in the right restaurant equipment ensures your new system doesn't collapse under the pressure of daily service.

Mastering Inventory with Smart Labeling and FIFO

A well-organized layout is a great start, but true mastery over your chest freezer comes down to your inventory game. It all boils down to a smart labeling system and an unwavering commitment to the First-In, First-Out (FIFO) principle. This isn't just about scribbling dates on a package; it’s about building a bulletproof system that anyone on your team can understand in a split second, even during the chaos of a dinner rush.

Forget flimsy labels. Your goal is a comprehensive system that holds up.

The best labeling method really depends on your kitchen’s unique flow. A simple waterproof marker is better than nothing, but a real commercial operation needs something more robust.

- Color-Coded Day-Dots: These are a classic for a reason. Assigning a different color to each day of the week gives your team an instant visual cue for what needs to be used first. It’s a perfect system for high-turnover ingredients, especially in a fast-paced spot like one of LA's many food trucks.

- Durable Freezer Labels: We’ve all seen it—standard labels peeling off in the cold and damp. You have to invest in labels specifically designed for freezing temperatures that will actually stick and stay readable.

- QR Code Systems: For the more tech-forward kitchens, slapping a QR code on each bin can link straight to a digital inventory sheet. A quick phone scan can reveal contents, prep date, use-by date, and quantity. It offers a level of detail and accuracy you just can’t beat.

If you want to dig deeper into identifying contents and managing stock, check out these effective methods for labeling storage bins. A clear, consistent system is the absolute bedrock of a successful inventory strategy.

Implementing a Foolproof FIFO System

The First-In, First-Out (FIFO) method is completely non-negotiable in a commercial kitchen. It’s the golden rule that ensures older stock is always used before new stock, which is critical for cutting down waste and protecting the quality of your food. In a chest freezer, this takes a little physical effort, but it pays off big time.

When a new delivery comes in, all the existing items in that particular zone need to be shifted forward or to one side. The new product goes in the back or at the bottom. This simple rotation guarantees that the oldest items are always the easiest to grab. Yes, it feels like extra work on a busy receiving day, but it saves a ton of money by preventing forgotten, freezer-burned product from being discovered months too late.

A strict FIFO policy is your best defense against food waste. It transforms your freezer from a place where food goes to be forgotten into an active, rotating extension of your pantry.

Think about a Los Angeles Pizza joint that prides itself on perfectly proofed dough. They could use vertically stacked, color-coded bins for their dough balls. When a new batch is ready, it goes into a bin at the bottom of the stack. During service, the cooks only pull from the top bin. It’s a simple, physical system that makes it nearly impossible to use dough out of order, ensuring every single pizza is up to their standard.

Keep Inventory Visible Without Opening the Lid

Every single time that freezer lid opens, cold air rushes out and your compressor has to kick into overdrive. It's a waste of energy and money. A simple but incredibly powerful tool to fight this is an external inventory list. A magnetic whiteboard stuck right on the freezer lid is a fantastic, low-tech solution that just works.

Jot down your main categories and their current quantities. For example:

- Beef Patties: 4 bags (Prep: 10/26)

- House-Made Chili: 12 quarts (Prep: 10/24)

- Brioche Buns: 3 packs (Rec'd: 10/27)

Train your staff to update the board every single time they take something out. It's a small habit that saves countless minutes of digging through the freezer and keeps energy costs down by keeping the lid shut. Staff can see what’s on hand at a glance, which makes prep and service run that much smoother. It’s a small change that makes a huge difference in your kitchen's daily efficiency.

Choosing the Right Tools for an Organized Freezer

A brilliant freezer layout is one thing on paper, but it’s the tools you use that make it work in the real world. The right restaurant equipment is what separates a system that holds up during a chaotic dinner rush from one that completely falls apart. Think of this as your buyer’s guide to the accessories that will finally tame that chest freezer.

Investing in quality, commercial-grade gear isn't just about looking tidy. It's about building a bulletproof system that can handle the daily grind of a busy Los Angeles kitchen. The goal here is simple: pick tools that squeeze every bit of value out of your freezer space and make inventory dead simple for your entire crew.

Bins, Baskets, and Dividers: The Foundation of Your System

Your primary storage containers are the absolute first thing you should invest in. When you’re picking out these foundational pieces, durability and smart design are non-negotiable.

- Heavy-Duty Plastic Bins: You need stackable, square or rectangular bins made from thick, freezer-safe plastic. Skip the flimsy stuff you’d buy for home use—it’ll just crack in the cold. A Los Angeles Pizza joint, for example, could use deep, lidded bins to wrangle bulk bags of shredded mozzarella, keeping it contained and easy to grab.

- Wire Baskets: These are perfect for those awkwardly shaped items or bulk bags of things like frozen fries or vegetables. The open design helps air circulate and lets staff see what’s inside at a glance, which speeds up service.

- Sturdy Dividers: To create and maintain your freezer zones, you need dividers that won't budge. Heavy-duty wire racks are a solid, adjustable option. For a more permanent fix, I’ve seen restaurants use custom-cut plexiglass sheets. They’re a pain to set up initially but are incredibly durable and easy to clean.

The cardinal rule of freezer containers is simple: always choose square or rectangular shapes. Round containers create significant "dead air" space between them, wasting valuable freezer real estate you can't afford to lose.

Knowing how much your freezer can actually hold is also a key part of your equipment strategy. A single cubic foot of freezer space can hold about 25 pounds of food. That means a standard 14 cubic foot freezer can accommodate up to 350 pounds. For any restaurant operator, understanding your freezer's capacity helps prevent the kind of overcrowding that kills air circulation and ruins food quality.

Smart Packaging and Visibility Tools

Beyond the big containers, a few other tools are essential for keeping your system running smoothly, especially if you’re dealing with prepped sauces or proteins common in Mexican Food spots.

First off, a commercial-grade vacuum sealer is a must-have piece of restaurant equipment. It’s not just about preventing freezer burn and extending shelf life; vacuum sealing creates flat, uniform packages that you can store vertically, like files in a cabinet. This trick alone can dramatically boost your space efficiency compared to lumpy, irregular packaging.

Next, think about how you package liquids. Reusable silicone bags are a fantastic, eco-friendly choice for stocks, sauces, and purees. You can freeze them flat to save a ton of space, and they’re tough enough to handle the abuse of a commercial kitchen.

Finally, don't forget about visibility. A deep chest freezer can feel like a black hole, making it impossible to read labels. A game-changing—and cheap—upgrade is to install a few small, battery-operated LED motion-sensor lights inside. They pop on the second the lid opens, lighting everything up so your staff can find what they need fast and get the lid closed again.

When you're ready to select the right unit for your restaurant, it pays to look through a comprehensive guide on the best commercial freezer options out there. It’ll help you find a model that ticks all the boxes for your kitchen’s needs, from size and energy use to long-term durability.

Keeping Your Freezer Clean and Safe

Getting your freezer organized is a huge win, but the real magic happens with consistent upkeep. Let’s be clear: this isn't just about keeping things neat. It's your frontline defense for protecting thousands of dollars in inventory, keeping your customers safe, and upholding your restaurant's hard-earned reputation.

A clean, well-monitored freezer is what keeps your ingredients at peak quality and ensures you’re always ready for a surprise health inspection. Think of your organization system as the blueprint for your house. The routine maintenance? That's the work that keeps the foundation strong and the roof from leaking. It’s what stops a little ice buildup from becoming a full-blown equipment failure.

The Defrost and Deep-Clean Playbook

If you're running a manual-defrost chest freezer, ice is just a fact of life. Once that frost layer hits about a quarter-inch thick, it's time for a defrost. Any thicker and that ice acts like a winter coat, forcing your compressor to work overtime, wasting electricity, and risking the temperature swings that ruin food.

The key is to schedule this for a slow day or after hours to keep service running smoothly.

Here’s your game plan for a quick, effective defrost:

- Set Up a Temp Home: Before you unplug a single thing, get your coolers and ice packs ready. A secondary freezer is even better. Your inventory needs a safe, cold place to hang out.

- Power Down and Empty Out: Pull the plug and transfer everything out. This is a great chance to inspect every item for freezer burn and double-check those dates.

- Melt the Ice (Safely): You can let it melt on its own, but placing a few pans of hot water inside and closing the lid will seriously speed things up. Whatever you do, never use a knife or scraper to chip away ice. It's a fast track to puncturing the freezer wall and buying a new unit.

- Drain and Sanitize: Once the ice is gone, drain the water. Then, give the entire interior a thorough wipe-down with a food-safe cleaner—a simple mix of vinegar and water or baking soda and water works perfectly.

Even the most organized freezer can get a little funky sometimes. If you're struggling with lingering smells from that forgotten container of stock, you'll need to tackle stubborn odors to get it fresh again.

A regular cleaning schedule isn't just a good idea; it's a non-negotiable part of running a professional kitchen. It protects everything from your food quality to your health score. Being proactive is always cheaper than dealing with a crisis.

Food Safety Isn't Optional

Beyond just being clean, your freezer has one primary job: staying cold. The industry-wide standard is -18°C (0°F) or below. That’s the magic number that halts the growth of bacteria and other microbes that cause spoilage and illness.

Don't just trust the freezer's built-in dial. Place an independent, calibrated freezer thermometer inside and make checking it part of your daily opening or closing checklist. This simple habit can alert you to a failing compressor before you lose your entire inventory. If the power goes out, keep that lid shut. A full, well-maintained chest freezer can keep its contents frozen solid for about 48 hours.

Proper packaging is the other side of the safety coin, especially for delicate items used by Los Angeles food trucks or in Mexican Food concepts. The enemy is air, and the result is freezer burn. A commercial vacuum sealer is your best friend for proteins, sauces, and anything you need to portion. For items like house-made chorizo or tamales, a tight wrap in plastic followed by a layer of foil or a freezer bag creates a formidable barrier. This two-step process locks out air, preserving the texture and flavor you worked so hard to create.

For a more comprehensive look at equipment care, be sure to check out our guide on commercial kitchen equipment maintenance.

Got Questions About Organizing Your Chest Freezer? We've Got Answers.

Even with a solid plan, questions always come up. Keeping a commercial chest freezer organized isn’t a one-and-done job; it's something you have to stay on top of, especially when your menu changes or suppliers shift. We hear it all the time from restaurant and food truck owners across Los Angeles—from battling that stubborn layer of ice to figuring out how to stop tiny, expensive items from vanishing into the abyss.

Let's tackle some of the most common hurdles you'll face. Here are some quick, practical answers to help you solve those nagging problems and fine-tune your freezer strategy.

How Often Should I Defrost My Commercial Chest Freezer?

For most manual-defrost freezers, you'll want to defrost it whenever the ice gets about a quarter-inch thick. In a busy kitchen, that usually means putting it on the calendar two to four times a year.

Don't push it longer. Once that ice builds up, it acts like an insulator, making your freezer’s compressor work way harder just to maintain temperature. That extra effort burns through electricity and, even worse, can cause temperature swings that compromise the quality and safety of your food. Plan your defrost for a slow day and have coolers with ice packs ready to go—it’ll minimize downtime and keep your inventory safe.

What's the Best Way to Organize Small, Loose Items?

Ah, the little stuff. Small, loose items are notorious for getting lost in the deep freeze, usually ending up buried at the very bottom. The trick is to group them before they have a chance to disappear.

- Use smaller, color-coded bins or even tough canvas tote bags. A Mexican Food restaurant, for instance, might have a small red bin for "Frozen Chiles & Herbs" and a blue one for "Portioned Fruit Purees."

- Think of these bins as freezer drawers. Instead of digging around, your crew can just lift out the whole bin to grab what they need.

- A vacuum sealer is also a game-changer here. It turns loose or awkwardly shaped items into neat, flat, stackable packages. You can file them vertically, just like folders in a cabinet.

Should I Use Round or Square Containers?

This one's easy: always, always go with square or rectangular containers. It's probably the single biggest space-saving move you can make.

Round containers create so much wasted "dead air" between them. Those little wedge-shaped gaps add up fast, costing you valuable real estate. Square containers, on the other hand, pack together perfectly with zero gaps, letting you use every last inch of freezer space. When every cubic foot counts, this is a no-brainer. Look for stackable, modular designs that fit together like puzzle pieces.

It's like packing a truck. You wouldn't use barrels if you wanted to fit as much as possible inside, right? The same logic applies to your freezer. You get maximum efficiency when everything fits together tightly.

Does a Whiteboard on the Freezer Lid Actually Work?

You bet it does. A simple magnetic whiteboard on the freezer lid is a surprisingly effective, low-tech way to keep a running inventory. Its biggest advantage is that it's right there in your face—no logins, no special training.

The only catch? You have to make it part of your kitchen's routine. List your main categories, quantities, and prep or delivery dates. Then, drill it into your team: if you take something out, you immediately update the board. This one simple habit stops people from constantly opening the lid just to see what’s inside, which saves a ton of energy and keeps your temperature stable. It's a small change that delivers big results.

At LA Restaurant Equipment, we know that the right tools are the foundation of an efficient kitchen. Whether you need a high-capacity chest freezer, sturdy prep tables, or top-tier cooking equipment, we provide new, warranty-backed gear at warehouse-direct prices to help your Los Angeles or Orange County business succeed. Check out our full selection of commercial kitchen solutions and see how we can help you build a more profitable operation from the ground up.