Think of a hot food counter as more than just a piece of kitchen equipment. It's a front-and-center sales tool, a heated stage for your culinary creations, keeping everything safely above 140°F while looking absolutely irresistible. For Los Angeles pizza shops, food trucks, and Mexican restaurants, where food culture moves at a breakneck pace, these units are non-negotiable for serving quick, quality meals.

The Secret Sales Engine in Your Restaurant

Picture the lunch rush. A line is forming at a popular Los Angeles food truck or a busy Mexican restaurant. What’s grabbing everyone's attention and making them add one more item to their order? It’s the sight—and smell—of that perfectly displayed hot food, sitting there ready to go. This is exactly where quality restaurant equipment like a hot food counter becomes an absolute game-changer.

Let's be real: in a grab-and-go world, people eat with their eyes first. A clean, well-lit hot display turns a simple menu description into a tangible, mouth-watering reality. When a customer sees those fresh tacos, steaming carnitas, or golden-brown pizza slices right in front of them, it creates an instant craving. That kind of direct visual marketing is what drives impulse buys and gets people excited to try new things.

Boosting Service Speed and Efficiency

For businesses where speed is everything, like pizzerias and Mexican food spots, hot food counters are the backbone of the operation. They completely streamline the serving process, letting your team plate up pre-made items in seconds. The whole setup is a masterclass in efficiency.

It works wonders for:

- Slashing Wait Times: Customers see their options, point, and pay. In and out. That's a huge deal during a slammed lunch service.

- Improving Kitchen Workflow: Your cooks can focus on batch cooking and keeping the line stocked, while your front-of-house crew can serve customers without missing a beat.

- Locking in Food Quality: By holding everything at a steady, safe temperature, you’re guaranteeing that every single customer gets a meal that's not just delicious but also fully compliant with health codes.

When your most popular dishes are kept hot, fresh, and visually appealing, you're not just meeting the demand for fast service—you're actively encouraging customers to buy more. It’s a fundamental tool for turning foot traffic into profit.

At the end of the day, picking the right hot food counter isn't just an expense; it's a strategic investment in your restaurant equipment. It has a direct line to your operational speed, your customer's experience, and your daily revenue, making it a must-have for any serious Los Angeles restaurant or food truck.

Steam Tables vs. Dry Heat Displays: What Your Menu Needs

When you're picking a hot food counter, it really comes down to one big question: moist heat or dry heat? The right answer is all about your menu. Each method is built to keep certain foods at their absolute best, and getting this choice right is everything for quality, texture, and taste.

Think of a steam table—sometimes called a bain-marie—as a gentle sauna for your food. It uses a well of hot water to create a humid, steamy environment, which is perfect for anything that needs to stay juicy and tender. This moist heat is your best friend for preventing delicate foods from drying out over a long service.

On the flip side, a dry heat display works more like a warm, circulating oven. It uses heating elements and fans to wrap food in dry, hot air. This is the undisputed champion of crispiness. It’s what keeps your fried or baked goodies holding that perfect texture without turning into a soggy mess.

Matching Heat to Your Menu

For a classic Los Angeles Mexican restaurant, a steam table isn't just nice to have—it's essential. How else do you keep barbacoa, carnitas, beans, and rice perfectly moist and ready to pile into tacos and burritos? Dry heat would wreck these dishes in no time, leaving them tough and unappetizing.

Now, picture a Los Angeles pizza parlor or one of the many popular LA food trucks selling fresh empanadas. They live and die by dry heat. This is what keeps pizza crusts firm and that fried chicken skin golden and crispy. A steam table in this scenario would be a total disaster, turning that beautiful crunch into a soft, steamy tragedy.

The rule of thumb is simple: match the holding environment to how the food was cooked in the first place. Moist foods need moist heat. Crispy foods need dry heat. If you get this wrong, you're compromising the very thing that makes your food great.

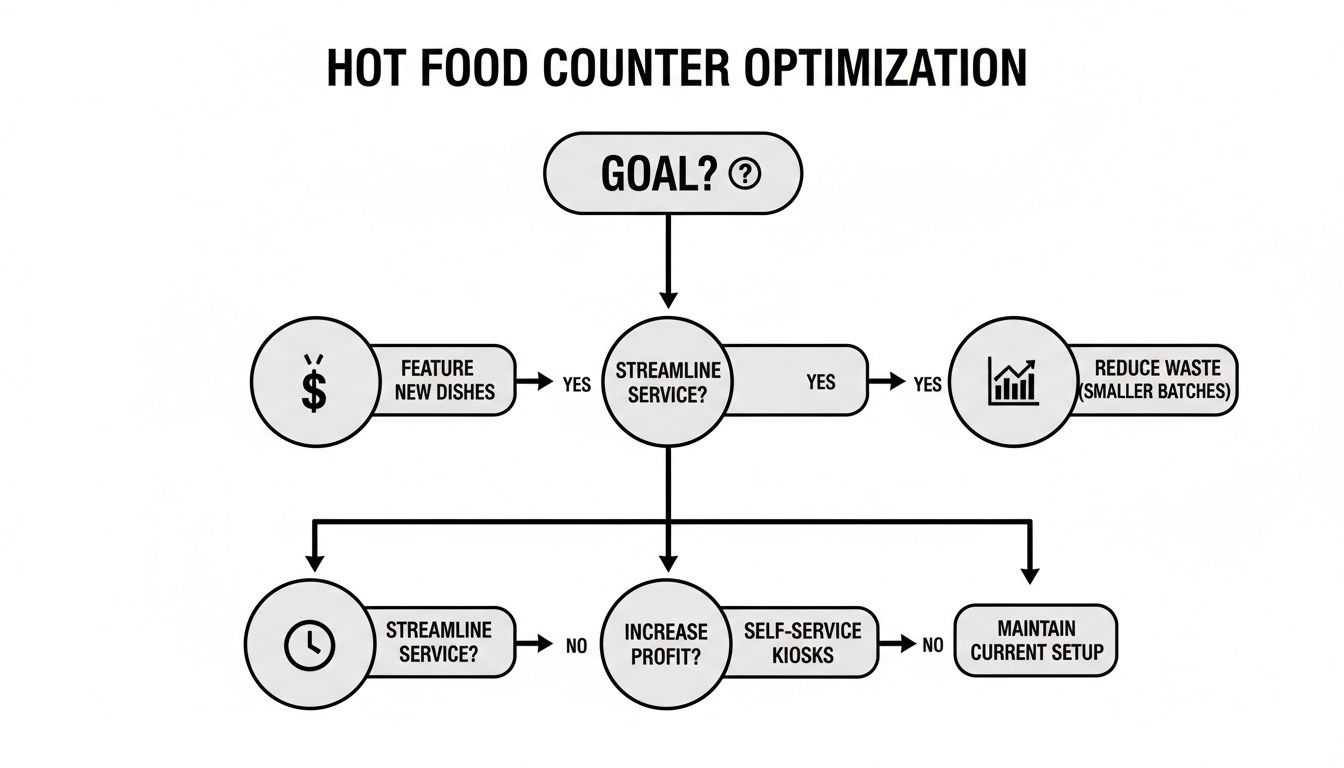

This flowchart breaks down how picking the right hot food counter is a direct line to hitting your business goals, from pumping up sales to making service run smoother.

As you can see, getting your restaurant equipment aligned with your kitchen's needs is the first real step toward a more efficient and profitable operation.

Steam Table vs Dry Heat Counter At a Glance

Still on the fence? This quick comparison should help you decide which hot food counter is the right fit for your menu.

| Feature | Steam Table (Moist Heat) | Dry Heat Counter |

|---|---|---|

| Best For | Sauces, stews, mashed potatoes, pasta, rice, beans, braised meats, and steamed vegetables. | Fried chicken, pizza, french fries, onion rings, pastries, breaded items, and empanadas. |

| Heat Transfer | Uses hot water vapor to gently surround food, preventing it from drying out. | Uses heating elements and fans to circulate hot air, maintaining crispiness. |

| Key Advantage | Forgiving environment that excels at preserving moisture and texture for hours. | Keeps fried and baked foods perfectly crispy without making them soggy. |

| Main Drawback | Requires water monitoring and refilling. Can make crispy items soggy. More cleanup involved. | Can dry out foods that aren't meant for it. Requires careful temperature management. |

| Energy & Maintenance | Generally uses more energy to heat water. Prone to mineral buildup (scaling) over time. | Often more energy-efficient and heats up faster. Simpler to clean. |

Ultimately, your menu is the final boss here. Let the food you serve dictate the restaurant equipment you buy.

For a deeper dive into the containers you’ll be using with these units, check out our guide on selecting the right full-size steam table pan for your setup.

Essential Features of a High-Performing Hot Food Counter

Okay, so you've figured out whether you need moist or dry heat. Now for the real nitty-gritty. The specific features of a unit are what separate a reliable kitchen workhorse from a daily headache. Looking past the basic heating method is absolutely critical if you want to choose a hot food counter that will actually pay off for your Los Angeles restaurant or food truck in the long run.

Think of the following points as your personal buyer's checklist. Getting these right from the start will save you from a world of hurt—costly repairs, spoiled food, and service bottlenecks. It’s about making a smart investment in your restaurant equipment from day one.

Temperature Controls and Food Safety

Getting the temperature right isn't just about serving delicious food; it's a legal must. Health codes demand that hot food be held at or above 135°F to stop nasty bacteria from growing. You might see older units with simple analog dials—you know, the "low-medium-high" kind—but they just don't offer the precision you need to stay compliant.

That’s why a digital thermostat is non-negotiable in today's world. It lets you lock in an exact temperature and see it with a quick glance, making sure every dish stays safely out of the temperature "danger zone." For a busy Mexican restaurant in Los Angeles, that precision means your carnitas and rice are always held at a safe, compliant temperature, protecting both your customers and your hard-earned reputation.

Materials and Construction

In any commercial kitchen, equipment has to be two things: tough and easy to clean. This is exactly why stainless steel is the undisputed king for high-quality hot food counters. It can take a beating day in and day out, shrugging off dents, rust, and corrosion without breaking a sweat.

Even more important is how easy it is to sanitize. Stainless steel has a non-porous surface, so spills and food particles wipe right off. This is absolutely essential for preventing cross-contamination and sailing through health inspections. Sure, you might save a few bucks upfront on cheaper materials, but they’ll quickly scratch, stain, or degrade, creating tiny hiding spots for bacteria and leading to much bigger problems down the road.

NSF certification is your golden ticket. It's a guarantee that a piece of equipment has been rigorously tested and approved for public health and safety. For any restaurant operating in Los Angeles County, that NSF mark isn't just a nice-to-have feature—it's a flat-out requirement for passing your health inspections.

Gastronorm Pan Compatibility

Picture this: you just dropped a good chunk of change on a beautiful new hot food counter, you get it installed, and... none of your existing food pans fit. It’s a frustrating and expensive mistake that’s surprisingly easy to avoid by understanding Gastronorm (GN) sizing. It's the universal standard used across the entire industry for food pans, trays, and containers.

Here’s a quick rundown of the common GN sizes you'll see:

- GN 1/1: This is your full-size base unit (around 20.75" x 12.75").

- GN 1/2: Exactly half the size of a full pan. Two of these fit perfectly into one GN 1/1 slot.

- GN 1/3: One-third the size. You can fit three of these in a full slot, perfect for holding smaller portions or different toppings.

- GN 1/4, 1/6, 1/9: Even smaller sizes designed for condiments, sauces, and garnishes.

Making sure your new restaurant equipment is GN-compatible means you can slot your existing pans right in, no sweat. This flexibility is a game-changer for everyone, from a Los Angeles pizza shop organizing its topping station to a food truck trying to maximize every inch of its serving space. Always look for units that clearly state their GN capacity to guarantee a perfect fit for your operation.

How to Size Your Hot Food Counter for Maximum Profit

Picking the right size for your hot food counter is one of those decisions that can make or break your service flow. It's a real balancing act. Go too small, and you're guaranteed to hit a bottleneck during the lunch rush, leaving customers frustrated and sales on the table. But go too big, and you’re just wasting energy and chewing up valuable floor space.

The goal is to find that sweet spot where the equipment perfectly supports your menu, your sales volume, and the physical space you’re working with.

This is especially true here in Southern California, where the entire food scene is being shaped by the demand for quick, portable meals. Hot food counters are a perfect fit for the grab-and-go trend, which is already driving 2-4% of retail sales growth in the U.S.

For the many Los Angeles food trucks and local Mexican restaurants, this is a massive opportunity. Hot convenience foods have seen demand jump by a whopping 25%. (You can dig into more of those consumer trends in Circana's 2026 outlook.)

Calculating Your Capacity Needs

Instead of just eyeballing it, you can get a pretty accurate idea of your needs with a simple calculation.

Figure out your absolute busiest two-hour window of the day. During that time, track exactly how many portions of your most popular hot items you sell. That number gives you a solid, data-backed baseline for the minimum capacity you need to keep things moving without your staff having to constantly refill the wells.

Let's look at a couple of real-world Los Angeles scenarios:

- High-Volume Los Angeles Pizza Shop: A pizzeria selling slices by the dozen needs a multi-level dry heat merchandiser. It has to hold several different types of pizza at once to keep that line from snaking out the door.

- Compact Food Truck: A taco or burrito truck in LA is all about maximizing a tight space. A powerful countertop steam table is the perfect restaurant equipment solution for holding essentials like carnitas, rice, and beans hot and ready to go.

Your sizing choice directly impacts your bottom line. The right unit makes sure every square inch of your investment is generating revenue by serving customers quickly. The wrong one just becomes a costly, underused appliance.

Matching Footprint to Function

Once you've figured out your food capacity, it's time to break out the tape measure. Measure the space you have available, but don't forget to account for the clearance you'll need for proper ventilation and for your team to move around safely and comfortably.

A big, full-size floor model might seem like the obvious choice for a hotel's busy breakfast buffet line. But for a small café's hot sandwich station, a more compact countertop unit is probably the much smarter, more efficient choice.

This same logic applies when you're thinking about cold storage, too. To get more ideas on optimizing your kitchen layout, check out our guide on choosing an under counter fridge size.

Ultimately, taking the time to translate your unique operational needs into the right equipment specs will help you sidestep some very common—and very costly—mistakes.

Understanding Installation, Maintenance, and Total Cost

So you’ve picked out the perfect hot food counter. Awesome. But let's talk about what happens after it arrives at your door. The practical side of owning this restaurant equipment—installation, daily upkeep, and the true cost over time—is what really separates a great investment from a future headache.

Getting these details right from day one is your best bet for keeping that unit running smoothly and safely for years to come. It’s how you’ll avoid those unexpected repair bills and operational hiccups that can throw a wrench in service, whether you're running a Los Angeles pizza parlor or a food truck in the Valley.

The first hurdle is installation, and it almost always comes down to your electrical setup. The smaller, more compact countertop units? They’re pretty straightforward. Most will run on a standard 120V outlet, the kind you have all over your kitchen.

But the bigger floor models, the real workhorses, often need more juice. They typically require a dedicated 220V circuit. That usually means calling in an electrician to get you set up. And don't forget ventilation—it’s not just a suggestion, it's a critical, non-negotiable step for safety and for staying on the right side of local fire codes.

Protecting Your Investment with Simple Maintenance

Want to get the most life out of your restaurant equipment and keep the health inspector happy? It all comes down to routine maintenance. A simple daily and weekly checklist is your best defense against the most common performance issues.

Daily Maintenance Checklist:

- Wipe Down All Surfaces: At the end of every shift, give all the stainless steel surfaces (inside and out), glass shields, and handles a good cleaning with a food-safe sanitizer.

- Empty and Clean Water Pans: If you're using a steam table, drain those water wells completely. This simple step prevents nasty mineral buildup and stops bacteria from growing.

- Check Temperature Accuracy: Don't just trust the digital display. Grab a separate thermometer to double-check that your food is staying above that critical 135°F safety zone.

Consistent care does more than just keep your hot food counter looking pristine for customers. It stops minor issues from spiraling into major, expensive repairs. Honestly, it's the single most effective way to protect your investment.

When you're budgeting for a hot food counter, it's easy to get fixated on the sticker price. But it's crucial to look beyond that and consider the long-term expenses. Taking the time to learn about reducing total cost of ownership for your equipment is a savvy move that will save you money down the line.

The Real Cost and Smart Financing

The price of new hot food counters can swing wildly, from a few hundred dollars for a basic countertop model to several thousand for a big, multi-well floor unit.

It can be tempting to browse the used market to save a buck, but that route is often filled with hidden risks. You're usually looking at no warranty, potential defects you can't see, and a completely unknown repair history. Is it worth the gamble?

Investing in new, reliable restaurant equipment is almost always the smarter long-term play. And with smart financing options, it's more accessible than ever. You can get a high-quality unit with manageable monthly payments, which keeps your cash flow free for all the other things your business needs.

For a deeper dive into keeping all your gear in top shape, check out our guide on commercial kitchen equipment maintenance.

Your Partner for Restaurant Success in Los Angeles

We’ve covered the ins and outs of choosing the right hot food counter, from temperature controls to pan sizes. Now for the final piece of the puzzle: finding the right restaurant equipment supplier. Working with someone local who truly gets the Los Angeles scene isn't just a small perk—it's a massive advantage, bringing you faster delivery and support that actually understands your needs.

This isn’t just about making a sale. It’s about building a real relationship with a team that’s invested in the success of our local culinary community, whether you're running a Los Angeles pizza shop, a food truck, or a popular Mexican food spot.

The Local Advantage: Warehouse-Direct Pricing and Expert Support

When you team up with a dedicated local partner, you get access to warehouse-direct pricing. This cuts out the expensive showroom markups you see with the big national chains. We pass those savings straight to you, making it easier to afford the high-quality, reliable restaurant equipment you deserve. Forget about rolling the dice on used gear; a new, warranty-backed unit from a trusted brand gives you peace of mind and performance you can count on.

That local connection means you get:

- Lightning-Fast Delivery: With our warehouse right here in Southern California, we can get essential equipment to your door in just one or two business days. No more waiting around and losing money.

- Real, Responsive Service: Need a quote or have a question? You’ll talk to a dedicated rep who knows the LA food scene inside and out. No call centers, no runaround.

- Guidance That Matters: We’ll give you expert advice to make sure you select the perfect model for your specific kitchen, ensuring your investment starts paying off from day one.

The demand for these units is absolutely exploding. The global food display counter market is on track to jump from $980.73 million in 2025 to $1.04 billion in 2026, all thanks to our growing appetite for ready-to-eat hot meals. Think about it: well-presented food can boost impulse buys by up to 30%. That makes your choice of a hot food counter one of the most important restaurant equipment decisions you'll make. You can discover more insights about the growing food display market from recent industry research.

Got Questions? We've Got Answers

We talk to Los Angeles restaurant owners every single day, and a few questions about hot food counters always pop up. Let's tackle them head-on so you can feel confident in your decision.

What’s the Magic Number for Temperature?

Health codes are crystal clear: all hot food has to stay at 135°F (57°C) or higher to keep bacteria at bay. That's the bare minimum.

But for the best taste and texture, most chefs I know shoot for a sweet spot between 140°F and 165°F. The perfect temp really comes down to what you're serving. Juicy carnitas served in a Mexican restaurant are happy around 150°F, but anything crispy needs that higher, drier heat to avoid getting soggy. Always, always use a food thermometer to double-check the food's internal temperature—it's about quality and passing your next inspection.

How Do I Stop My Food from Turning into a Desert?

It's a classic problem. Dry heat is a lifesaver for fried chicken served from a food truck, but it can absolutely wreck other dishes. Here’s a simple trick I’ve seen work wonders: just place a small, heat-safe pan of water inside the display. It adds just enough moisture to the air to keep things from drying out.

Also, give your food some breathing room. Overcrowding the counter blocks airflow and creates weird hot and cold spots. If you're holding delicate items, it’s often better to cook in smaller batches and refresh the display more often than to let a huge pan sit for hours.

Can I Use the Same Counter for Pizza and Tacos?

Honestly, trying to make one piece of restaurant equipment work for both is a recipe for disappointment. A dry heat counter is what you need to keep pizza slices from your Los Angeles pizza shop perfectly crisp and ready to go. But fillings for Mexican food, like barbacoa or al pastor, need the gentle, moist environment of a steam table to stay tender and delicious.

If you've got a diverse menu, your best bet is to use separate, smaller countertop units designed for each job. It’s a specialized approach, but it means you’re serving every single item at its absolute best instead of compromising on everything.

Ready to find the perfect hot food counter for your Los Angeles restaurant, food truck, or catering business? Explore our full range of new, warranty-backed restaurant equipment at LA Restaurant Equipment and get the performance and reliability you need with fast, local shipping. Visit us today at https://larestaurantequipment.com to get started