For any successful restaurant in Los Angeles, keeping your commercial ice machine in top shape isn't just a chore—it's a non-negotiable part of the business. It’s all about a consistent routine: cleaning, sanitizing, and checking key parts to sidestep expensive breakdowns, keep your food safe, and run an efficient kitchen. Think of it as protecting your restaurant equipment and making sure you're always on the right side of health codes.

Why Ice Machine Upkeep Is Crucial For Your LA Kitchen

In the breakneck pace of the Los Angeles food scene, an ice machine is far more than just another piece of restaurant equipment; it's the heartbeat of your beverage service. It doesn't matter if you're running a slammed Los Angeles pizza joint, a trendy Los Angeles food truck, or a beloved local spot for Mexican food—running out of ice can stop your operation dead in its tracks. Putting off maintenance isn’t a minor slip-up; it's a direct threat to your revenue and your reputation.

This guide isn't about adding another task to your list. It's about reframing commercial ice machine maintenance as a core business strategy. It’s how you protect your gear, keep your customers safe, and stay profitable in LA's cutthroat culinary world.

The Hidden Costs of Neglect

One of the biggest headaches for Los Angeles restaurants is Southern California's notoriously hard water. It's loaded with minerals that, over time, build up into a chalky substance called scale inside your machine. This forces the unit to work way harder than it should, quietly jacking up your energy bills and tanking its performance.

This constant strain is just asking for a total breakdown, and you know it will happen during the Saturday night dinner rush when you can least afford it. The costs pile up fast, and it’s not just about the repair bill:

- Lost Revenue: An "out of order" sign on the ice machine means no iced drinks. That's a huge hit to sales, especially when the weather heats up.

- Emergency Repairs: A frantic, last-minute call to a technician is always going to cost more than a scheduled maintenance visit.

- Reduced Lifespan: A machine that's been run into the ground will die years before a well-maintained one, forcing you to shell out for replacement restaurant equipment you weren't planning on.

For issues that go beyond basic upkeep, having access to reliable plumbing solutions for businesses across the greater Los Angeles area can be a real lifesaver.

Market studies show that in a busy hub like Los Angeles, maintenance can make up 20-30% of a machine's annual operating costs. Skipping it often leads to scale buildup that can slash efficiency by up to 15%.

Health Codes and Customer Safety

Forget the money for a second; there are serious health concerns to think about. The inside of an ice machine is warm, dark, and damp—the perfect breeding ground for mold, slime, and bacteria. If you let that go, these contaminants end up in your ice, creating a real health risk for your customers.

If a health inspector finds contaminated ice, you're looking at serious penalties. We're talking hefty fines, a mandatory cleaning order, or even a temporary shutdown. In a city where your reputation is everything, the fallout from a failed health inspection can be devastating. Proper maintenance is your first and best defense to make sure you're serving clean, safe ice every single time.

Building Your Daily And Weekly Maintenance Routine

Consistency is the real secret to keeping your commercial ice machine humming. It’s not about adding a bunch of complicated chores to your staff’s already packed schedule; it’s about creating simple, repeatable habits that everyone—from the prep cooks to the manager—can follow. Think of it as a small daily investment that prevents catastrophic failures down the line.

Every LA kitchen has its own rhythm. A high-volume taco spot in East LA after a slammed Cinco de Mayo weekend will have different immediate cleaning needs than a quiet coffee shop in Silver Lake on a Tuesday morning. The core tasks are the same, but knowing your operational tempo helps you stay ahead of the game. A solid daily and weekly plan is your first and best line of defense.

Your Daily Ice Machine Checklist

These daily checks should take less than five minutes, but they're absolutely critical for catching small issues before they snowball. Anyone on your staff can handle these at the beginning or end of a shift. The goal is just to spot anything that looks off.

- Wipe Down Exterior Surfaces: Grab a clean, damp cloth and a food-safe cleaner to wipe down the machine’s outside—the door, handle, and any surrounding panels. This quick step prevents kitchen grease and grime from building up and eventually making its way inside.

- Sanitize the Ice Scoop: That scoop is a high-contact item that can become a superhighway for bacteria. It needs to be cleaned and sanitized daily. Crucially, store it outside the ice bin, preferably in its own sanitized holder.

- Visually Inspect the Ice: Take a quick glance at the ice itself. Is it clear? Are the cubes fully formed? If you see cloudy, slushy, or undersized cubes, that’s an early warning sign. It often points to a problem with the water filter or the beginnings of scale buildup, letting you know a deeper clean is on the horizon.

A quick daily once-over prevents minor oversights from turning into major headaches. It’s a tiny investment of time that pays off big, much like the other routines that keep a kitchen running smoothly. For a wider look at this philosophy, check out our guide on general commercial kitchen equipment maintenance for more tips.

The Weekly Maintenance Refresh

Once a week, you'll want to set aside a bit more time for a deeper check-in. This routine hits the spots that don’t need daily attention but are vital for long-term performance, especially in the demanding environment of a busy LA pizzeria or food truck.

A weekly routine is where you shift from just spotting problems to actively preventing them. This is your chance to really clean key parts and inspect for wear and tear before it causes an unexpected shutdown during a dinner rush.

Here’s a practical checklist to run through every week:

- Thoroughly Clean the Ice Bin: Start by emptying all the ice from the storage bin. Use a solution of mild detergent and warm water to scrub every interior surface—bottom, sides, and all the corners where gunk likes to hide. Rinse it completely to get rid of any soap residue, then sanitize it with a food-grade sanitizer (follow the label's instructions to the letter) and let it air dry completely.

- Inspect Water Lines and Connections: Do a quick visual check on the water lines going in and out of the machine. You're looking for any drips, leaks, or sharp kinks in the hoses. Even a slow, unnoticed leak can cause serious water damage or create a dangerous slip hazard in your kitchen.

- Check and Clear the Air Vents: If you have an air-cooled machine (most are), the vents are magnets for dust and airborne kitchen grease. Wipe them down and make sure nothing is blocking airflow. Proper ventilation is essential for preventing the machine from overheating and failing.

To make things even simpler, here's a quick-reference table you can post near the machine. It helps manage the simple yet critical tasks needed to keep your commercial ice machine in peak condition.

Daily vs. Weekly Maintenance Tasks At A Glance

| Task Frequency | Maintenance Action | Why It Matters For LA Businesses |

|---|---|---|

| Daily | Wipe down the exterior of the machine | Prevents buildup of kitchen grease and grime in a busy environment. |

| Daily | Clean and sanitize the ice scoop | High-contact item; crucial for meeting LA County health code standards. |

| Daily | Visually inspect ice for clarity and size | Early warning system for water quality issues or scale buildup. |

| Weekly | Empty and deep clean the ice storage bin | Removes biofilm and prevents mold/slime growth, ensuring safe ice. |

| Weekly | Inspect water lines for leaks or kinks | Prevents water damage and slip hazards, a major liability concern. |

| Weekly | Clear air vents on air-cooled units | Ensures proper cooling to avoid overheating, especially in hot kitchens. |

By breaking down your ice machine care into these simple daily and weekly chunks, you create a sustainable system that actually works. This approach guarantees your machine runs efficiently, produces clean and safe ice, and serves your Los Angeles restaurant reliably for years to come.

Deep Cleaning Your Ice Machine The Right Way

Daily and weekly wipe-downs are your first line of defense, but the real battle for your ice machine’s longevity is won with a periodic deep clean. This is where you roll up your sleeves and tackle the two biggest threats to your equipment’s health and your customers’ safety: mineral scale and biological contaminants.

For any Los Angeles restaurant, especially those dealing with Southern California's notoriously hard water, mastering this process is non-negotiable. It’s a methodical process of descaling and sanitizing that protects your investment in quality restaurant equipment. Getting this wrong can lead to damaged components and costly repairs down the line.

Understanding Descaling vs. Sanitizing

First things first, it’s crucial to know that descaling and sanitizing are two completely different jobs, and the order you do them in matters immensely. You must always descale first, then sanitize.

Trying to sanitize a machine caked in mineral buildup is like trying to wash your hands with gloves on—it just doesn't work. The scale creates a protective shield for bacteria and slime to hide under, making your sanitizer totally ineffective.

- Descaling: This is all about removing the hard, chalky limescale that builds up from mineral-rich water. You’ll use a specialized, acidic solution to dissolve it. Think of this as the mechanical fix that keeps water flowing and parts moving correctly.

- Sanitizing: After the scale is gone, this step uses a food-grade sanitizer to kill any bacteria, mold, and other nasty stuff that's been growing inside. This is a non-negotiable health and safety requirement.

A popular spot for Mexican food in LA can't afford the downtime from a clogged machine, nor the health code violation from contaminated ice. One process keeps the machine running; the other keeps the ice safe to serve.

Preparing Your Machine for a Deep Clean

Before you even think about opening a bottle of cleaner, proper prep is key. Rushing this can lead to damaged equipment or, worse, an incomplete cleaning job.

- Empty the Machine Completely: Get all the ice out of the storage bin. It’s smart to schedule your cleaning when ice levels are naturally low to minimize waste.

- Power Down Safely: Turn the machine off using its control panel, then go the extra step and unplug it from the wall or shut off the circuit breaker. This is a critical safety step.

- Shut Off the Water Supply: Find the main water shutoff valve for the ice machine and turn it completely off. This prevents a surprise flood while you're working.

Once the machine is safely powered down and disconnected, you're ready to start taking apart the components for a thorough cleaning.

Pro Tip: Always have your machine's user manual handy. It will show you exactly how to remove specific parts like the water curtain, distribution tube, and various sensors without breaking them. Every model is a little different, so don't guess.

Executing the Cleaning Process

With everything prepped, it's time to get to work. The most important rule here is to use the right products. Never, ever use bleach or other unapproved chemicals. Always grab a nickel-safe ice machine cleaner for descaling. Many evaporators and other internal parts are made of nickel-plated metal that can be destroyed by the wrong stuff.

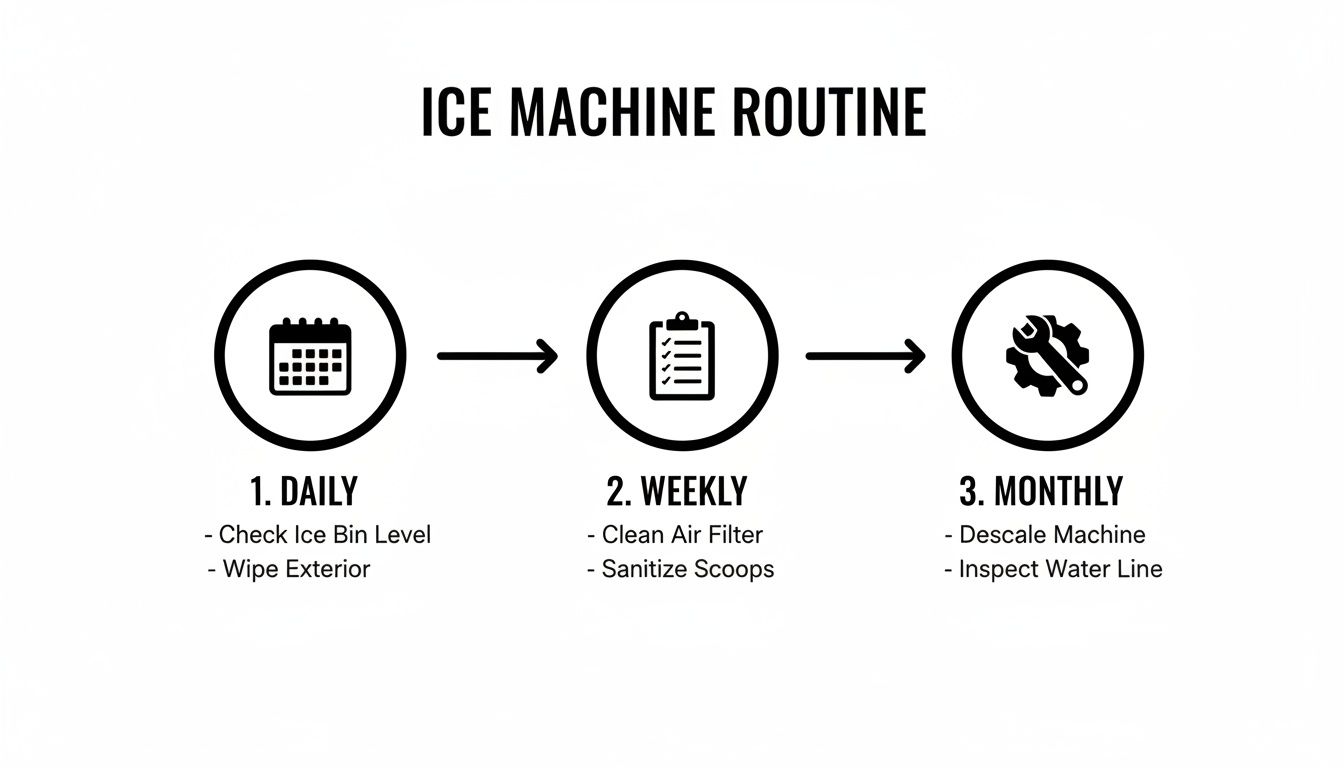

This infographic breaks down the essential maintenance routines to keep in mind.

As the visual shows, those consistent daily and weekly tasks are the foundation that makes these deeper cleans more effective.

After you've removed the key components, circulate the descaling solution through the system according to the manufacturer's instructions—most machines have a "clean" or "wash" cycle for this. Scrub any remaining scale off the parts you removed, rinse everything thoroughly, and then put it all back together.

Once the descaling is done and all parts are back in place, you can run the sanitizing solution through the system using the same cycle. A final, thorough rinse with fresh water is essential to remove any trace of chemicals.

For specific models, like the ones you see in so many Los Angeles pizza spots, you can find detailed walkthroughs to guide you. For example, if you need specific guidance, you can learn more about how to clean a Manitowoc ice maker in our dedicated article.

Finally, don't forget to clean and sanitize the storage bin itself. A perfectly clean ice-making system dropping ice into a dirty bin defeats the whole purpose. Let all components air dry completely before turning the water and power back on. Run one or two small batches of ice and toss them out to ensure the system is fully flushed before you start serving customers again.

How To Inspect And Replace Key Components

Proper ice machine maintenance is about way more than just cleaning. It's about getting your hands dirty and catching the small signs of wear and tear before they explode into a full-blown crisis.

For any busy LA spot—whether it's a Los Angeles food truck slinging tacos or a pizzeria with a non-stop drink station—an unexpected breakdown is a complete disaster. Learning to inspect and, when necessary, replace a few key components is one of the best ways to keep that from ever happening.

Taking a proactive approach puts you in the driver's seat, helping you spot issues early and saving you from a frantic, expensive emergency call during a dinner rush.

Inspecting Your Water Filters

I can tell you from experience, the single most common culprit behind bad ice and slow production in Los Angeles is a clogged water filter. Southern California's notoriously hard water is packed with minerals and sediment that absolutely wreck filters, and that’s where the problems start.

A clogged filter chokes the water flow, meaning the machine is starved for water and can't produce a full batch of ice. This is why you start seeing small, cloudy, or hollow cubes that melt instantly and can even taste off—something no restaurant can afford.

How to spot a failing water filter:

- Reduced Ice Production: If your bin isn't filling up like it used to, a clogged filter is almost always the reason.

- Poor Ice Quality: Cloudy, slushy, or weirdly shaped cubes are a classic sign that not enough water is getting to the evaporator plate.

- Low Water Pressure: A lot of filter systems have a pressure gauge built right in. If you see the needle dropping, it’s time for a change.

Most manufacturers will tell you to change the water filter every six months. But in a high-sediment area like LA, you might need to swap it out as often as every three months. A pro tip: grab a sharpie and write the date you changed it right on the filter housing. You’ll never have to guess.

Cleaning Air Filters And Condenser Coils

If your ice machine is an air-cooled model—and most are—its ability to breathe is everything. The air filter and the condenser coils work together to pull heat away from the guts of the machine. In a busy kitchen loaded with airborne grease and dust, these parts get filthy, fast.

Once the air filter or condenser coils get clogged, the machine can't cool itself down. This forces the compressor to work overtime, jacking up your energy bills and putting incredible strain on the whole system. Eventually, it just gives out.

Cleaning the air filter is a simple task that has a huge payoff. Most just slide right out and can be washed with warm, soapy water. Just be 100% sure it’s completely dry before you put it back in. The condenser coil, which looks like a metal grill, should be cleaned at least quarterly. A stiff brush and a vacuum are all you need to get the built-up gunk off.

A machine that can’t breathe is a machine that’s working itself to death. A five-minute air filter cleaning can prevent a multi-thousand-dollar compressor replacement.

Checking Gaskets, Seals, And Electricals

Beyond the filters, a few other parts need a regular once-over to make sure everything is running efficiently and safely.

Key Components to Watch:

- Gaskets and Seals: Check the seals around the door and bin. If they’re cracked, brittle, or loose, cold air is leaking out. That makes the machine work harder and causes condensation to build up.

- Water Lines and Tubing: Give the water supply lines and internal tubing a quick look. You’re searching for any cracks, kinks, or tell-tale signs of a leak. A tiny drip today can become a flooded kitchen tomorrow.

- Electrical Components: You should always leave the heavy electrical work to a pro, but you can absolutely do a visual inspection. Look for frayed power cords and make sure all connections are snug. To really get a handle on your machine, it helps to understand what's going on inside; learning about internal Understanding Contactor Components can give you a much deeper knowledge of how it all works.

By making these simple inspections a part of your routine, you and your team can catch small problems before they become big headaches. This proactive mindset is what separates a smooth-running kitchen from one that’s constantly putting out fires.

Troubleshooting Common Ice Machine Problems In Your Restaurant

Even with the most diligent maintenance schedule, every kitchen manager knows that sinking feeling. You hear a strange noise from the ice machine, or worse, you realize it's stopped making ice altogether. When your Los Angeles restaurant runs on a constant supply of fresh, clean ice, a breakdown can bring service to a grinding halt.

The good news is that you can often fix the most common issues yourself without an emergency service call. Before you pick up the phone, running through a quick diagnostic checklist can get your machine back in business.

Diagnosing Low Or No Ice Production

This is, by far, the most frequent—and frustrating—problem. The lunch rush is hitting, your staff is screaming for ice, and the bin is barely refilling. A few key culprits are almost always to blame.

- Check the Water Supply: It sounds almost too simple, but you'd be surprised how often this is the root cause. Make sure the water valve connected to the machine is fully open and that the supply line isn't kinked or pinched.

- Inspect the Water Filter: In Southern California, a clogged water filter is public enemy number one. If it’s blocked with sediment, not enough water can get through to make a full batch of ice. This often leads to small, hollow cubes or no ice at all.

- Examine the Bin Sensor: Most machines use a sensor or a small curtain arm to detect when the bin is full. Sometimes, a single stray ice cube can get wedged in the wrong spot, tricking the machine into thinking it's full and shutting down production.

If your machine has stopped producing ice entirely, we have a detailed guide that can help you figure out exactly why your ice machine is not making ice and what to do about it.

Tackling Leaks And Water Issues

Discovering a puddle spreading out from under your ice machine is an alarming sight. Leaks don't just waste water; they create a serious slip-and-fall hazard in an already chaotic kitchen.

More often than not, the source is a clogged or poorly positioned drain line. If the line is blocked with slime and other gunk, the meltwater from the bin has nowhere to go and will eventually overflow. Another potential issue is a leaky water inlet valve, which might just need a quick tightening or, in some cases, a replacement.

Industry data shows that poor upkeep is the reason behind 60% of failures in undercounter and air-cooled machines. These breakdowns can cost a restaurant over $1,000 per day in lost business. In places like Southern California, service calls shot up 15% in 2023 because hard water accelerates mineral buildup, which can slash ice production by 25% if you don't stay on top of it. You can discover more insights about market trends on Technavio.com.

Addressing Poor Ice Quality Or Bad Taste

If you get a complaint that a drink tastes "off," the ice is often the secret suspect. This is the kind of problem that can quickly tarnish the reputation of any LA spot, whether it's a high-end Mexican food joint or the neighborhood pizza place.

Cloudy, soft, or foul-tasting ice is almost always a sign of a dirty machine or an old water filter. A complete deep cleaning and descaling cycle will usually solve it by eliminating any built-up slime or mold. If the problem sticks around after a good cleaning, it’s a clear sign your water filter is long overdue for a replacement.

This is a critical step in making sure the final product you serve is as clean and refreshing as it should be. Consistent commercial ice machine maintenance is your best defense against these common—and completely preventable—headaches.

Got Questions About Your Ice Machine? We've Got Answers.

Even with the best maintenance routine, you're going to have questions. Every restaurant owner in Los Angeles, whether you’re running a Los Angeles pizza joint or a Los Angeles food truck, has had that moment of "what's going on with my ice machine?" We hear a lot of the same questions, so we've gathered the most common ones right here to give you direct, no-nonsense answers.

How Often Do I Really Need Professional Service For My Ice Machine In Los Angeles?

For most spots in the LA area, you should plan on getting professional service at least twice a year. It’s no secret that our region has notoriously hard water, which means mineral scale builds up way faster than in other places. A technician’s visit should cover a deep, professional-grade cleaning, a full inspection of all the electrical and refrigeration parts, and a system calibration to keep it running right.

That said, if you’re a high-volume business—think a packed bar, a popular restaurant specializing in Mexican food, or a food truck that’s always on the go—you’ll probably want to bump that up to quarterly check-ups. It’s the best way to catch small problems before they become big, expensive ones.

What's The Difference Between Descaling And Sanitizing?

This is a big one, and it’s something every kitchen manager needs to get right. They're both part of the cleaning process, but they do completely different jobs.

- Descaling: This is all about fighting that hard water buildup. You use a special, acidic cleaner to break down and remove mineral deposits, also known as limescale. Think of it as a mechanical task to keep the machine's guts from getting clogged.

- Sanitizing: This step is for health and safety. You're using an EPA-approved, food-grade solution to kill off biological gunk like bacteria, mold, and slime.

Here's the golden rule you can't forget: always descale first, then sanitize. If you try to sanitize a machine that's still caked in scale, you're just wasting your time. The mineral buildup acts like a shield, letting germs hide out underneath where the sanitizer can't reach them.

Can I Just Use Bleach Or Something Else To Clean My Ice Machine?

Nope. Absolutely not. Never use unapproved chemicals on your ice machine, period. For descaling, you have to use a nickel-safe ice machine cleaner. A lot of the critical internal parts, especially the evaporator plate where the ice forms, are made of nickel-plated metal. Harsh chemicals will eat right through that plating and cause permanent damage.

For sanitizing, you need an EPA-approved food-grade sanitizer. Using something like household bleach is a triple threat: it can corrode your machine’s components, it will almost certainly void your warranty, and worst of all, it can contaminate your ice and make your customers sick.

Why Are My Ice Cubes Coming Out Small And Cloudy?

Small, cloudy, or hollow ice cubes are almost always a dead giveaway for a water problem. Nine times out of ten, especially here in Southern California, the culprit is a clogged water filter that's choking off the water flow to the machine. When the machine is starved for water, it just can't make those full, crystal-clear cubes.

Your very first move should be to check and replace your water filter. If a brand-new filter doesn't fix it, the problem is likely a dirty evaporator plate or a serious scale buildup that needs a full descaling and cleaning cycle.

Equipping your Los Angeles restaurant, bar, or food truck with reliable, high-performance restaurant equipment is the first step toward success. At LA Restaurant Equipment, we provide top-quality, warranty-backed commercial kitchen equipment at warehouse-direct prices, ensuring you get the best value without the risk of used items. From Atosa refrigeration to a full line of cooking equipment, we have everything you need to keep your operation running smoothly. Explore our inventory and see how we can help you today at https://larestaurantequipment.com.