An LA food truck owner was drowning in health‐code violations and kitchen backups—until a simple switch to a 3 compartment sink turned everything around. Within weeks, fines disappeared, service times dropped, and this setup became as common as the sidewalk carts outside Grand Central Market.

Why LA Kitchens Choose A 3 Compartment Sink

Think of the three basins like a clean dish relay: one station scrubs, the next rinses, and the final one sanitizes. No handoffs get contaminated, and health inspectors leave happy.

- Ensures consistent compliance with LA County health standards

- Cuts dish turnover time by up to 30% during peak service

- Protects staff and guests from foodborne illnesses

“Manual warewashing in a three-step sink is the backbone of safe, efficient kitchens,” says a local health inspector.

This three-phase ritual dates back to the 1918 flu pandemic, which exposed massive sanitation gaps and claimed 50 million lives worldwide. By 1940, the FDA enshrined wash-rinse-sanitize as the global hygiene playbook. Today, more than 90% of commercial kitchens in regulated markets rely on it, stopping outbreaks that cost operators USD 55 billion every year. Market momentum has pushed the sector to USD 1,500 million by 2025, with a 6.5% CAGR forecast through 2033. Discover more insights about the 3 compartment sink market on Market Report Analytics

Next, we’ll unpack each cleaning phase in step-by-step detail, sharing real-world examples from LA food trucks, pizzerias, and Mexican kitchens to highlight workflow gains—and guide you on the smartest buying decisions.

What Readers Will Learn

- Core wash-rinse-sanitize procedures, explained with down-to-earth analogies

- Sizing calculations and material comparisons for trucks versus brick-and-mortar

- Installation and plumbing tips for fully compliant setups

- Maintenance routines and sanitation best practices

- When a dishwasher or portable station makes more sense

- Buying, financing, and shipping options tailored to LA Restaurant Equipment

Understanding How 3 Compartment Sink Works

Think of a three-compartment sink as a three-stage spa treatment for your dishes: wash, rinse, then sanitize. Each basin plays its own critical role in turning grimy plates into spotless, safe dinnerware.

It starts in the wash basin, heated to 110–120°F, where detergents break down grease and stubborn food particles. From there, dishes move to the clear-water rinse at 110–115°F, flushing away suds and any lingering detergent.

Finally, they land in the sanitize basin—171°F water or an NSF-approved chemical bath that kills 99.9% of bacteria on contact (we saw that exact result in an LA pizzeria trial).

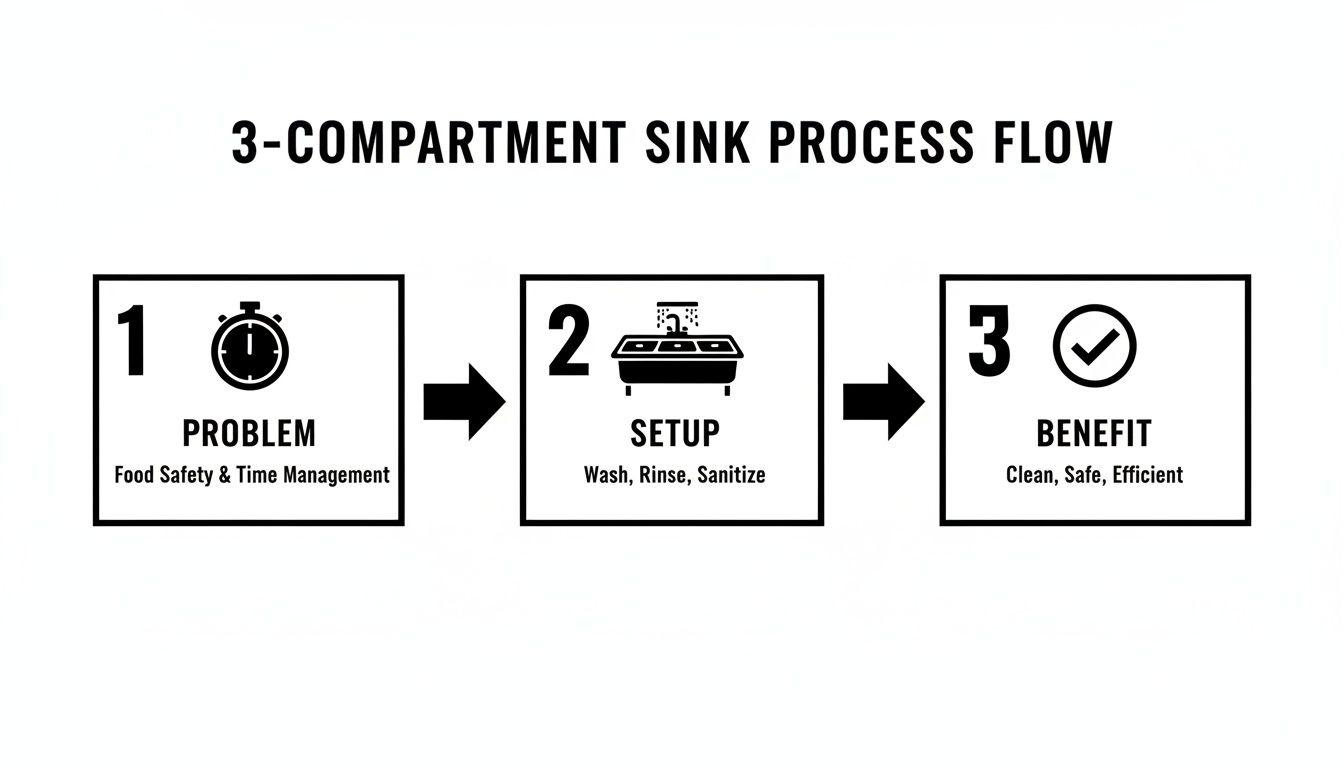

The flowchart below maps out common timing snags, highlights setup steps, and points to the efficiency gains you can expect.

In that study, smart sequencing boosted throughput by 30%. And by adding a pre-rinse sprayer to tackle dried-on cheese, scrape time dropped by 20%, keeping orders flowing.

Wash Stage Details

In Basin 1, hot detergent water starts the process. Staff should scrub every item for at least 30 seconds, using brushes or wash modules to lift off grease and debris.

- Keep the temperature between 110–120°F for peak detergent action

- Choose an NSF-certified warewashing detergent; follow the label dosage

- Swap out the wash solution whenever it turns murky or suds build up

- Pre-rinse heavily soiled items under a hands-free sprayer before scrubbing

Rinse Stage Details

Basin 2 holds 110–115°F clear water to remove any soap film before sanitizing. A quick 10 second dip is all it takes.

- No chemicals needed—just a gentle, even flow

- Check water clarity often; change it when particles accumulate

- Keep utensils separated to prevent recontamination

Let’s break down the Wash, Rinse, and Sanitize stages side by side.

Wash Rinse Sanitize Process Comparison

| Step | Purpose | Temperature | Chemical Required | Time |

|---|---|---|---|---|

| Wash | Remove grease & food debris | 110–120°F | Warewashing detergent | 30 sec minimum |

| Rinse | Flush away soap residue | 110–115°F | None | 10 sec dwell |

| Sanitize | Kill remaining pathogens | 171°F | Chlorine (50–100 ppm) or quat | 30 sec minimum |

This table gives your team a quick-read snapshot of each stage’s key metrics.

Sanitize Stage Details

Basin 3 is where safety happens. You have two options:

- Hot-water sanitizing at 171°F for at least 30 seconds—no chemicals required

- Chemical sanitizers (chlorine or quats) at label-specified strengths for the same contact time

Always verify your local health-code rules and the sanitizer label. Consistent temperatures and dwell times are non-negotiable.

“Proper water temperature and contact time are non-negotiable for safe sanitization.” – LA Health Inspector

Ergonomic Sprayers And Drainboards

A well-designed station boosts speed and cuts fatigue:

- Hands-free spray valves expand your cleaning reach without extra touch points

- Front-mounted sprays let staff rinse large pans in place

- Sloped drainboards return water to the sinks, keeping floors dry and safe

By mastering these wash-rinse-sanitize steps—and pairing them with ergonomic touches—you’ll meet Los Angeles health-code standards, slash turnover times, and keep every dish shining.

Next, we’ll look at how to choose the right sink size and materials for your kitchen’s layout.

Choosing Size And Material

Sizing a three-compartment sink begins with mapping your peak dish volume against the real estate in your kitchen. Think of it like choosing a delivery van—you need enough capacity to handle the busiest hour, without cramming into a spot meant for a compact car.

In tight food-truck kitchens, a 48″ truck-mount sink often hits the sweet spot. Meanwhile, a 72″ stationary model shines in brick-and-mortar restaurants juggling heavy plate loads.

Key sizing factors include:

- Peak dish count per hour to prevent wash-line backups

- Available wall space and plumbing clearance

- Rush-period output targets, driven by menu complexity

Comparing Sink Sizes

A 48″ Truck-Mount Unit is the nimble choice for food trucks and pop-up kitchens. It delivers about 45 gallons of basin volume and processes 500–600 items per hour. Low ceilings and narrow service windows won’t stand in its way.

A 72″ Stationary Model, by contrast, feels like a workhorse. With roughly 70 gallons of capacity and generous drainboards, it powers through 800–1,000 items per hour—perfect for taquerias and pizzerias.

-

48″ Truck-Mount Unit

- Ideal for pop-up kitchens and food trucks

- Handles 500–600 items per hour

-

72″ Stationary Model

- Best for brick-and-mortar taquerias and pizzerias

- Processes 800–1,000 items per hour

Before ordering, double-check cold-water hookups and drain slopes against local LA health codes. Measure wall studs, floor drains, and utility runs so your installation goes off without a hitch.

Evaluating Material Options

Choosing between stainless-steel grades is a lot like picking the right vehicle trim: you want something that stands up to daily wear, but won’t blow your budget.

| Material | Durability | Cost | Maintenance |

|---|---|---|---|

| 304 Stainless Steel | High | Moderate | Wipe and sanitize |

| 316 Stainless Steel | Very High | High | Regular rinse-down |

| Corrosion Alloys | Very High | Very High | Occasional polish |

| Eco Coated Surface | High with coating layer | Moderate | Reapply coating |

Take one LA pizza kitchen that upgraded to 16-gauge sinks and saw a 30% reduction in replacements over two years—fewer dents, less rust.

“Choosing the right gauge and finish can cut replacement costs dramatically,” says a restaurant operator experienced in high-volume pizza service.

Materials must also align with OSHA slip- and sanitary-rule standards to breeze through inspections.

On a global scale, the compartment sink market hit USD 1,145 million in 2025 and is forecasted to nearly double by 2035. With hygiene mandates in over 70% of foodservice outlets, three-phase cleaning can cut bacterial risk by up to 99.9% per NSF studies. Dive into the Compartment Sink Market Report for the full breakdown.

When choosing your sink:

- Balance budget against expected lifespan

- Match capacity to peak service demands

- Factor in maintenance schedules and labor costs

- Verify compliance with LA health and OSHA rules

Material costs can vary by up to 20%, so get detailed quotes from LA Restaurant Equipment. Many SoCal suppliers even throw in free shipping within one to two business days—minimizing downtime.

Lock in financing now to avoid last-minute scrambles.

By weighing these factors, you’ll land on a sink that fits your workflow, your wall space, and your budget. Next, we’ll cover installation tips to ensure a compliant and efficient setup.

Installing Your 3 Compartment Sink

Before you begin, ensure your LA health-code permits are approved and on file.

Measure the underfloor drainage clearance and test your water pressure now to avoid surprises later.

This quick prep will keep costly rework and inspection delays at bay.

Next, choose the mounting style that fits your kitchen flow:

- Wall-Hung: lifts your sink off the floor and opens up real estate, but requires reinforced studs behind drywall.

- Drop-In: nests into your counter and works with most base cabinets—no extra framing needed.

Leveling Brackets And Anchors

Position the sink at the height where it feels natural—usually around waist level—and lay a spirit level across the edge to check for plumb.

Mark bracket points, drill pilot holes, and secure the sink with heavy-duty anchors or lag bolts rated for basin loads.

- Locate studs or beams before drilling to avoid weak spots.

- Use a torque wrench to tighten anchors uniformly.

- Give the sink a firm press at the edges to verify stability.

Plumbing Best Practices

Run hot water lines at a ¾-inch diameter to each basin to maintain steady flow.

Install P-traps beneath each drain to block sewer gases and prevent backflow.

Angle the drain boards at roughly 1/4 inch per foot so water clears naturally without pooling.

“Proper P-traps and drain angles keep clogs at bay,” advises a certified plumber.

Check that each valve delivers at least 2 psi for effective rinsing performance.

Troubleshooting Installation Issues

Even a small misalignment can cause leaks around joint connections—tighten fittings and swap out old gaskets.

If you spot slow drainage, adjustable couplings can correct the pitch between the sink and floor drain.

Backflow often points to misaligned trap primers. Ensure trap heights meet local code.

- Common leak points: drain flanges and valve threads.

- Always level the P-trap and run a pool test before finalizing.

Case Study Low Ceiling Food Truck

A taco truck operator faced just 60 inches of headroom. They chose a compact drop-in sink, shaving 4 inches off standard basin height.

By rerouting the plumbing under a 6-inch header beam and experimenting with bracket placement, they cleared inspectors while keeping the workflow smooth.

Installation Roadmap

- Secure permits and document permit numbers.

- Mount leveling brackets, set the sink squarely, and anchor it with precision.

- Connect hot and cold water lines; slip in P-traps under each drain.

- Perform leak tests, verify no backflow, and check drain clearance.

- Record pressure readings, photograph each step, and wrap up the inspection.

With these steps, your 3 compartment sink will be ready for daily service.

Check out our guide on Commercial Kitchen Layout Design to optimize your workspace before installation.

Remember to document every pressure test and snap progress photos for the health inspector.

Final Tips

- Use anchors rated for sink loads and inspect anchor tightness every 6 months.

- Attach a thermal strip to the sanitizer basin to confirm 171°F accuracy.

- Schedule a professional plumbing inspection quarterly to avoid downtime and fines.

Proactive maintenance keeps your sink running longer and cuts repair costs.

Proper installation lays the groundwork for smooth service.

Start your install with confidence—contact LA Restaurant Equipment for fast shipping and expert support.

Maintaining And Sanitizing Your Sink

A three-compartment sink is the workhorse of any busy kitchen. Each basin plays a vital role—picture them as relay racers handing off spotless dishes to the next station. Skip a beat, and the whole team slows down.

One East LA taqueria trimmed 20% off end-of-shift cleaning times by adding ergonomic drainboards. That small tweak made a big impact. In the sections below, you’ll find routines and tips to keep your setup NSF-compliant and running smoothly.

“Neglecting minor maintenance invites major headaches,” warns a Los Angeles health inspector.

Daily Cleaning Routine

Start every shift with a quick once-over:

- Scrape food scraps into the trash or disposal.

- Fill Basin 1 with detergent and 110–120°F water. Scrub items thoroughly.

- Move to Basin 2 for a clear-water rinse—knock off any suds.

- Finish in Basin 3 with 171°F water or a 50–100 ppm chlorine bath.

- Wipe down basin walls and scrub the drain grid.

Tip: Keep a laminated checklist by the sink for consistency and speed.

Weekly Inspection Steps

A weekly walkthrough catches small issues before they grow:

- Check drain seals and under-sink fittings for leaks or cracks.

- Examine faucet gaskets for wear; replace loose ones right away.

- Spray valves should deliver a steady, even stream—no sputtering.

- Ensure drainboards slope correctly so water flows back into the sink.

Staying on top of these checks prevents surprise downtime.

Monthly Scale Removal

Hard water minerals can clog seams and slow down heat transfer. A simple descaling routine restores peak performance:

- Drain all three basins.

- Fill with a mild acidic solution (follow manufacturer guidelines).

- Let it sit for 30 minutes.

- Scrub with a non-abrasive brush, then rinse thoroughly and refill.

This step is a lifesaver in areas with tough water.

| Task | Frequency | Benefit |

|---|---|---|

| Basin scrubbing | Daily | Removes debris |

| Seal inspection | Weekly | Prevents hidden leaks |

| Scale removal | Monthly | Restores flow and heat transfer |

Sanitizer Dosing And Verification

Proper sanitizer levels are non-negotiable:

- Hot-water sanitizing: 171°F dwell for at least 30 seconds.

- Chemical sanitizers:

- Chlorine at 50–100 ppm

- Quaternary ammonium compounds as per label instructions

Always use test strips or digital probes to confirm both ppm and temperature.

The global commercial sink market was valued at USD 915.7 million in 2025 and is projected to hit USD 1,686.9 million by 2035, growing at a 6.3% CAGR. Learn more in the NSF-Approved 3-Compartment Sink overview.

Record Keeping And Log Templates

Digital logs with photo timestamps make health inspections painless. A solid log entry covers:

- Date and time of cleaning

- Staff member’s name

- Sanitizer ppm readings

- Water temperature checks

This creates a transparent audit trail. For more on record-keeping, check out our guide on Commercial Kitchen Equipment Maintenance in our article at LA Restaurant Equipment (https://larestaurantequipment.com/blogs/los-angeles-restaurants/commercial-kitchen-equipment-maintenance).

Preventive Maintenance Tips

A proactive approach keeps your sink—and your day—running without hiccups:

- Clean drip trays and the area beneath the sink to prevent odors.

- Lubricate faucet gaskets with food-grade grease every quarter.

- Keep spare seals, O-rings, and faucet aerators on hand.

- Flush debris from P-traps monthly.

- Sanitize drip trays weekly with a mild bleach solution.

Having the right parts close by means less downtime when something needs a quick swap.

Case Study On Ergonomic Improvements

At a bustling East LA taqueria, operators added a sloped drainboard with guard rails. The result?

- 15% reduction in mop-up time

- Less water pooling on the floor

- Noticeable drop in bending and wrist strain

Small ergonomic upgrades like this pay off in faster cleanups and happier team members.

3 Compartment Sink Applications in Los Angeles Pizza, Food Trucks, and Mexican Food Restaurants

Los Angeles Pizza Kitchens

High-volume pizzerias need a 72″ stationary 3 compartment sink to handle dough trays, sauce pots, and cheese pans. Stainless steel 304 is preferred for easy cleaning and acid resistance. Pair with deck ovens, dough mixers, and refrigerated prep tables to keep toppings fresh. Sloped drainboards save time when clearing pizza screens, and hands-free sprayers make quick work of flour build-up. When selecting equipment, use the commercial kitchen equipment checklist to ensure you’ve covered every station.

Los Angeles Food Trucks

Space is tight, so food trucks often install a 48″ truck-mount 3 compartment sink with deep basins and compact drainboards. A drop-in design nests under countertops alongside fryers, flat-top grills, and hot-holding cabinets. Ergonomic spray valves help clean off char marks, while portable hand sinks ensure compliance. Flexible plumbing kits make installations quick on the road. For a complete layout plan, visit Commercial Kitchen Layout Design.

Mexican Food Restaurants

Taquerias and Mexican eateries handle tortillas, salsa, and multi-tier steam tables every day. A 60″ sink with deep basins lets staff manage heavy sauce pots and steam pans. Many opt for stainless steel 316 in coastal areas to resist corrosion from lime-based cleansers. Install tortilla warmers, steam kettles, and prep stations nearby to keep the workflow tight. Free shipping within SoCal from LA Restaurant Equipment often includes NSF-approved accessories like faucet filters and sanitizing kits.

Purchasing Options And Alternatives

When you’re selecting a dishwashing system, you’re really weighing water usage, labor demands, and service speed. Comparing cycle times side by side with flow rates helps you pinpoint the actual cost per wash.

For a pop-up pizza stall, a compact three-compartment sink can tuck neatly under a tent. Meanwhile, a busy brick-and-mortar taqueria might see an undercounter dishwasher cut labor by 40% and save 23,000 gallons of water each year.

While automation trims manual tasks, remember it brings its own maintenance requirements.

If your busiest shifts aren’t too intense, a two-basin sink strikes a clever balance.

- Three-Compartment Sink: Clear wash, rinse, sanitize zones but higher water draw.

- Two-Basin Sink: Economical on water but demands strict timing to avoid cross-contamination.

- Portable Wash Stations: No hard plumbing needed, perfect off-grid, but lower throughput and more manual work.

Dishwashing Options Comparison

To help you weigh the trade-offs, here’s a side-by-side look at three common wash stations.

| Option | Throughput (racks/hr) | Water Usage (gal/cycle) | Labor Requirement | Typical Cost | Best Use Case |

|---|---|---|---|---|---|

| Manual 3 Compartment Sink | 100–150 | 3–5 | High | $1,000–$2,000 | Small stalls |

| Two Compartment Sink | 80–120 | 2–4 | Moderate | $800–$1,500 | Light duty use |

| Commercial Dishwasher | 250–300 | 1–3 | Low | $4,000–$8,000 | High volume kitchens |

This snapshot should clarify which setup matches your kitchen’s pace and volume.

Buying In Los Angeles

Southern California showrooms stock everything from Atosa prep tables to countertop pizza stations. The top suppliers—LA Restaurant Equipment, Universal Supply, and Javco Foodservice—offer on-site demos so you can test sprayers, drainboards, and basin depths.

- Free shipping in 1–2 days for in-state orders keeps downtime minimal.

- NSF-approved sink packages often come with warranty-backed covers.

Supplier Directory

At LA Restaurant Equipment’s Brea showroom, you’ll find live sink assemblies next to full prep lines. Universal Supply on Santa Fe specializes in custom stainless builds. Javco Foodservice in Anaheim carries multiple sink sizes with deep basins and integrated drainboards.

Check Yelp for peer reviews—local chefs and operators share candid feedback on service and reliability.

Financing And Shipping

Equipment loans let you spread costs over 12 to 60 months at competitive rates. Leasing preserves cash flow when upgrading to NSF-approved gear, and tax credits can cover up to 10% of energy-efficient stainless purchases.

- Loans typically require a 20% down payment.

- Lease agreements may include maintenance packages.

- Energy-efficient units qualify for accelerated depreciation and local incentives.

Schedule delivery during off-peak prep hours so your team can easily manage freight.

- Lift-gate service prevents delays when unloading heavy sinks.

- White-glove delivery bundles installation planning and debris removal into one seamless move.

Negotiate bulk deals on multiple units to secure 5–15% discounts. Lift-gate and white-glove services will cut installation time and headaches.

Check out our guide on commercial kitchen equipment checklist for a step-by-step shopping companion.

Whether you’re running a mobile stall or a full-service kitchen, choosing the right sink or dishmachine will streamline your workflow. Reach out to LA Restaurant Equipment for personalized quotes, bulk-order perks, and fast SoCal delivery. Speak with our sales team online or by phone to tailor your order—and enjoy the peace of mind that expert support brings.

FAQ

When questions pop up about basin sizes, steel grades, or glassware cleaning, this FAQ has you covered. Think of it as your quick-reference guide to installing and running a 3 compartment sink under LA’s health codes.

Whether you’re retrofitting an existing station or installing a brand-new unit, nailing these specs now saves time, money, and potential fines down the road. These answers follow LA County regulations and NSF guidelines for real-world clarity.

Minimum Basin Dimensions

LA health inspectors require each basin to be at least 15 inches by 15 inches with a depth of 10 inches. If you’d rather think in volume, that works out to 324 square inches per basin. Keep in mind, local jurisdictions may tweak requirements, so touch base with your health department.

- Footprint: 15″ x 15″

- Depth: 10″ minimum

- Volume: 324 sq in per basin

Always post printed cleaning logs beside the sink. It’s your best bet for smooth inspections and audit support.

Choosing Stainless Steel Grades

Most kitchens opt for 304 stainless steel—it’s food-safe, cost-effective, and widely available. On the other hand, if you’re steps from the ocean or running high-temperature washes, 316 stainless steel resists salt corrosion and harsh cleaners better. It carries a higher upfront price tag but can cut downtime and replacement costs in the long run.

“Grade 316 pays off in seaside environments, cutting corrosion and spare-part needs,” says a Los Angeles kitchen manager.

Glassware Washing And Sanitization

Picture glassware going through a three-stage spa: wash, rinse, sanitize. Dedicate one basin to fragile stems and fine glass. Use a mild detergent and a lower-pressure sprayer to prevent chips.

- Wash at 110–120°F

- Rinse at 110–115°F

- Sanitize at 171°F or with 50–100 ppm chlorine

Stick with NSF-approved sanitizers and test strips to confirm both temperature and ppm levels. A quick strip check ensures your glassware is guest-ready and code-compliant.

Make it a habit to review these FAQs with your team so your service stays efficient and inspection-ready all year long.

Ready to outfit your kitchen with top-grade sinks? Visit LA Restaurant Equipment for warranty-backed stainless steel sinks, free fast delivery, and flexible financing.