When you're trying to nail down the right undercounter refrigerator, think of it like finding the perfect puzzle piece for your kitchen's layout. These units are built to slide right under standard 36-inch high counters, but the real game-changers are the width and depth. Those two numbers dictate everything from your storage capacity to how smoothly your team moves, whether you’re in a tight Los Angeles food truck, a bustling pizzeria, or a popular Mexican food spot.

Your Quick Guide to Undercounter Refrigerator Dimensions

Choosing the right undercounter refrigerator is a lot like casting an actor for a movie role—it has to fit the scene and perform its job flawlessly. For a bustling Los Angeles pizza restaurant or a nimble food truck, getting the dimensions right from the start is the first step toward a smooth, efficient operation. This type of restaurant equipment is essential for success.

These units are the unsung workhorses of the kitchen, designed to slip neatly under countertops to put cold storage exactly where your staff needs it most. While they might look simple, small differences in width, height, and depth can completely change your kitchen's workflow. This is especially true here in Southern California, where every square inch of space counts.

Standard Commercial Sizes

In commercial kitchens, undercounter refrigerators have pretty much settled into a few standard size categories. This is a good thing, because it makes planning easier and ensures you can store a predictable number of food pans or kegs.

Globally, most units you'll see are between 27 and 72 inches wide. The depth usually hovers around 29–32 inches, and the height is almost always 34–36 inches. This consistency is by design—it lets them slide right under standard 36‑inch counters without a hitch.

Here’s a quick rundown of what these numbers really mean for your day-to-day:

- Height: The industry standard is locked in at around 34-36 inches. This ensures you get that clean, seamless look when you install it alongside your existing prep tables and cooking stations.

- Depth: Most units are 29-32 inches deep. This depth lines up perfectly with standard counters while leaving just enough space in the back for proper ventilation—something you can’t afford to mess up.

- Width: This is where you get to make the real choices. Widths can start as slim as 24-27 inches for those tight corners and go all the way up to 72 inches or more for high-volume prep lines that need massive capacity.

Before we get into the specifics of measuring, here’s a table that breaks down the standard commercial dimensions at a glance. Think of this as your cheat sheet for quickly figuring out what might work in your space.

Standard Undercounter Refrigerator Dimensions at a Glance

| Dimension | Standard Commercial Range | Why It Matters for Your Kitchen |

|---|---|---|

| Width | 24" to 72"+ | This is your biggest variable. It directly impacts your storage capacity and floor plan. |

| Depth | 29" to 32" | Needs to match your counter depth while leaving crucial breathing room for the unit to vent. |

| Height | 34" to 36" | Standardized to fit neatly under countertops for a seamless, ergonomic workspace. |

This table should give you a solid starting point. As you can see, while height and depth are fairly consistent, the width is where you'll be making your most important decision based on your kitchen's specific needs.

For a deeper dive into how your refrigerator's size plays into the bigger picture of kitchen flow and aesthetics, check out these practical kitchen cabinet design insights. Getting these fundamental measurements right is the first step to a truly optimized kitchen.

Finding the Right Width for Your Kitchen's Workflow

When you're shopping for an undercounter refrigerator, the width is the single most important number to focus on. It’s about more than just fitting the unit into a space; it dictates how your team moves, how they access ingredients, and ultimately, how productive your kitchen can be during a chaotic dinner rush.

Think of the width as the foundation of your under-the-line workflow. Get it right, and everything moves smoother. Get it wrong, and you create bottlenecks. The goal is to find that perfect balance between enough storage to keep the line stocked and enough open space for your crew to operate efficiently.

Matching Width to Your Kitchen's Needs

A slim unit squeezed into a Los Angeles food truck has a very different job than a sprawling three-door model anchoring the prep line at a high-volume Mexican restaurant. A wider unit isn't always the answer—if it’s overkill for the station, you're just disrupting foot traffic and wasting energy.

Let's break down how different sizes fit into the Southern California food scene:

- 27-Inch to 36-Inch Models: These are perfect for specialized stations or businesses with a tiny footprint. A downtown LA coffee bar can tuck a 27-inch unit under the counter for milk and creamers, while a food truck might use one for prepped garnishes without sacrificing precious floor space.

- 48-Inch to 60-Inch Models: This mid-range is the workhorse of the industry. A 48-inch unit is ideal for a Los Angeles pizza place's topping station. A 60-inch model gives you enough room for a whole spread of pans on a busy sandwich or salad line.

- 72-Inch and Larger Models: Built for the big leagues. Imagine a packed East LA spot on a Friday night serving Mexican food. A 72-inch unit is holding bulk quantities of salsa, carne asada, and produce, making sure the line never has to stop and restock.

Choosing the right width is a strategic decision that directly impacts speed and efficiency. By aligning the unit's size with its specific function—be it a beverage station, a topping rail, or a main prep line—you create a more logical and effective kitchen environment.

Which Undercounter Refrigerator Width Is Right for You?

Sometimes the easiest way to figure out what you need is to see it laid out. Here’s a quick guide comparing common widths with their typical uses to help you find the perfect match for your restaurant, bar, or food truck.

| Width | Best For | Typical Capacity (e.g., 1/6 Pans) |

|---|---|---|

| 27" - 36" | Small spaces, beverage stations, food trucks, low-volume prep. | 4-6 pans |

| 48" | Bar back-up, sandwich/salad stations, moderate-volume kitchens. | 8-10 pans |

| 60" | High-use prep lines, busy cafes, versatile general storage. | 10-12 pans |

| 72" | High-volume kitchens, pizza prep, main production lines. | 12+ pans |

This table gives you a solid starting point. Match the "Best For" column with your station's needs, and you'll be well on your way to picking a winner.

Translating Width into Real-World Capacity

At the end of the day, what really matters is how much stuff you can fit inside. The most practical way to think about undercounter refrigerator sizes is to ask: "How many food pans can it hold?" This simple question cuts through all the technical specs.

For instance, a 48-inch unit might comfortably hold eight 1/6-size food pans, while a 72-inch model could handle twelve or more. When you start thinking in terms of pan capacity, you can plan your menu prep and station layouts much more effectively.

This level of detail is exactly what you need to optimize your space. If you're looking for more guidance on fitting equipment into your floor plan, our article on commercial kitchen layout design offers some great insights for Southern California operators, making sure every piece works in harmony.

Why Height and Depth Are Critical for a Seamless Fit

Think of an undercounter refrigerator as a custom puzzle piece for your kitchen. While the width mostly dictates how much you can store, the height and depth are what make it either a perfect fit for your workflow or a daily headache. Nailing these two dimensions is non-negotiable for a smooth, functional kitchen line.

The 36-inch counter height is the gold standard in the commercial kitchen world. This isn't just a random number—it's the ergonomic sweet spot that makes hours of prep work comfortable and efficient. Because of this, nearly all commercial undercounter refrigerators are built to stand between 34 and 36 inches tall. This allows them to slide right under your existing cooktops and prep tables without a fuss.

The Standard Height and Its Variations

Getting that perfect, flush fit means you have to sweat the small stuff. A unit that's even a hair too tall simply won't fit, and one that’s too short creates an awkward, crumb-collecting gap that’s a nightmare to clean.

A couple of common factors can throw off the final measurement:

- Legs vs. Casters: Standard legs give you stability, but casters (wheels) are a lifesaver when it's time to deep-clean your floors. Just remember, adding casters will typically lift the unit’s height by 2-4 inches, so you absolutely have to factor that in.

- ADA Compliance: To ensure accessibility for everyone on your team, ADA-compliant models are designed with a lower profile. They usually sit around 32 inches high, making them easily usable for all staff members.

Getting the height right is about more than just looks; it's about creating a single, uninterrupted workspace. A refrigerator that lines up perfectly with your countertops keeps the workflow moving and gives your kitchen a clean, professional finish.

Why Depth Dictates Kitchen Flow

Depth is just as crucial, especially in the notoriously tight kitchens we see all over Los Angeles. Most commercial units are designed with a depth between 29 and 32 inches. This range is meant to sit flush with standard countertops, creating that clean, uniform look from the front.

But get it wrong, and you've got a problem. A refrigerator that’s too deep will stick out into walkways, creating a serious hazard for staff hustling with hot pans or full trays. In a cramped Los Angeles food truck or a narrow galley kitchen, even an extra inch can completely disrupt the flow of service. On the flip side, a unit that's too shallow is just wasted real estate under your counter.

Ultimately, measuring height and depth correctly saves you from expensive installation mistakes and ensures your new equipment makes your kitchen more efficient, not less. It’s the key to making sure your investment integrates seamlessly from day one instead of creating a whole new set of problems.

How Refrigerator Size Impacts Your Bottom Line

Choosing an undercounter refrigerator isn't just about making sure it slots neatly under the counter. It's a straight-up investment in your kitchen's financial health. The dimensions you pick are directly tied to the unit's cooling power, how much energy it sucks up, and what you’ll be paying on your monthly utility bills—a major chunk of overhead for any Southern California business.

There’s a common myth that a bigger fridge automatically means a bigger electricity bill. While it's true that larger units need more powerful compressors to cool a bigger space, modern engineering has completely changed the game. Today's most energy-efficient models often give you way more usable storage while costing significantly less to run than older, bulkier equipment.

The Connection Between Size and Energy Use

A unit’s size is the biggest factor in its energy consumption. A larger interior means the compressor has to work harder to keep everything at a food-safe temperature, especially in a blazing hot Los Angeles kitchen. But here’s the kicker: thanks to huge leaps in insulation and cooling tech, a brand-new 48-inch unit might be far more efficient than a five-year-old 36-inch model.

This is where the real savings kick in. Investing in a modern, correctly sized unit can lead to some serious long-term savings on your SoCal Edison bill. Think of it as a smart financial move that pays you back, month after month.

The decision is no longer just about physical dimensions or line layout; it's about cost efficiency. A modern undercounter refrigerator can reduce electricity costs significantly over a three- to five-year financing term, making it a powerful tool for managing overhead.

In fact, the global refrigeration industry, worth over USD 100 billion, is laser-focused on this blend of capacity and efficiency. The market is expected to balloon to about USD 154.77 billion by 2030, all driven by demand for smarter, more economical equipment. You can learn more about this trend and how it impacts the freezer market on this detailed industry report. For restaurant owners like us, this just means better and better technology is always around the corner.

Calculating Your Return on Investment

For a Los Angeles pizza spot or a busy food truck, every dollar shaved off the utility bill is a dollar that can go back into the business. Picking the right undercounter refrigerator size—based on both your workflow and its energy rating—is a huge part of this strategy.

Keep these points in mind when you’re weighing the financial impact:

- Energy Star Ratings: Make it a priority to look for models with an Energy Star certification. These units are proven to be more efficient, which means lower operating costs right out of the box.

- Insulation Quality: Thicker, better-quality insulation means the compressor doesn't have to kick on as often. Simple as that. Less work, less power used.

- Modern Compressors: Newer variable-speed compressors are a world away from old tech. They only use the exact amount of energy needed to maintain the temperature, unlike older models that just blast at full power all the time.

By carefully thinking through these factors, you can make sure your equipment isn't just another purchase, but a profitable asset. For a deeper dive into making your kitchen more cost-effective, check out our guide on energy-efficient commercial refrigerators that breaks down how modern appliances can slash your operational expenses.

Measuring Your Space to Ensure a Perfect Installation

There's nothing worse than the thud of a brand-new undercounter unit arriving, only to realize it's a quarter-inch too wide for the opening. It's the number one installation headache I see, and it brings a busy kitchen to a grinding halt.

To sidestep costly returns and blown project timelines, you've got to measure your space like a pro. This goes way beyond just pulling a tape measure across the opening once. Successful installation is all in the details. You need to account for ventilation clearances, the path your door will swing, and where your utilities are hiding. It’s like a puzzle—every piece, from an uneven floor to a stray pipe, has to be factored in for a seamless fit.

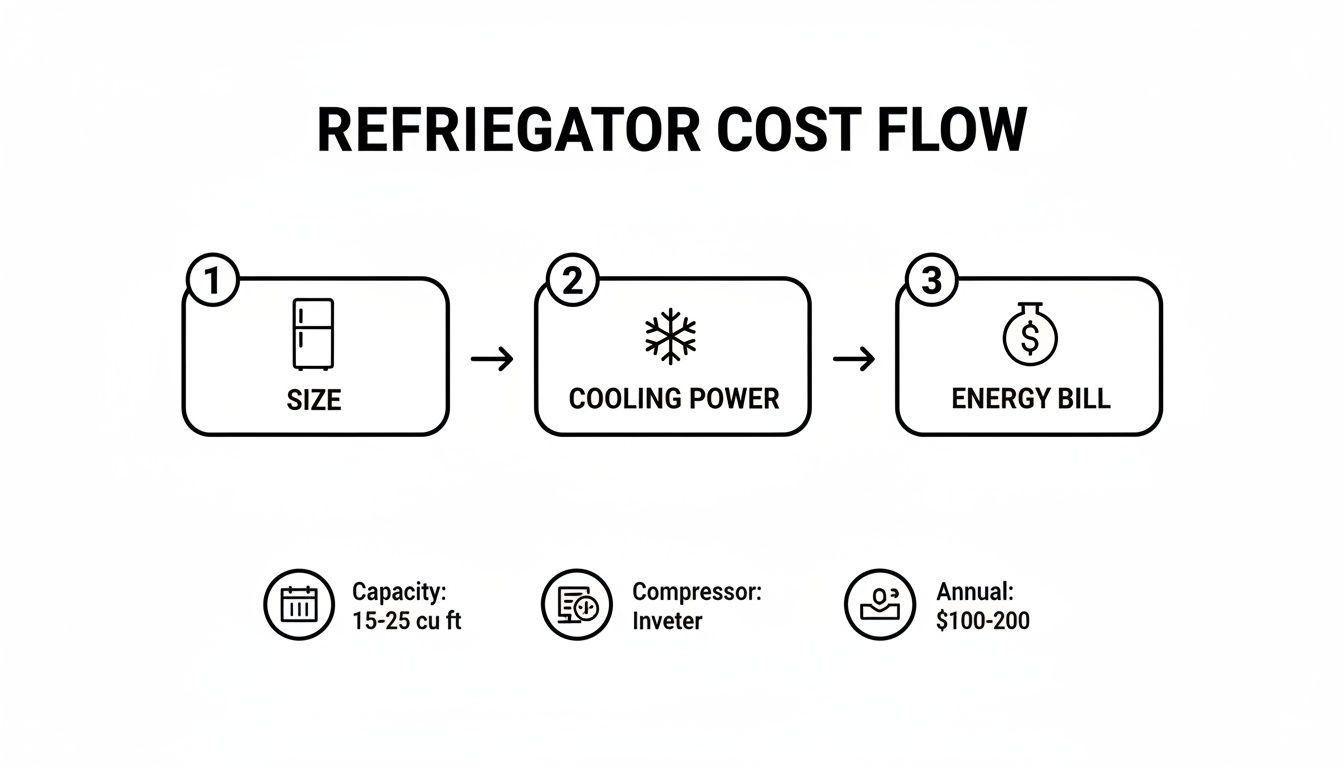

This simple flow shows how a refrigerator's physical size directly impacts its cooling power and, in the end, your annual energy bill.

The takeaway here is pretty clear: getting the size right isn't just about fitting it in the hole; it's about optimizing energy use and saving money on your utility bills month after month.

The Professional Measurement Checklist

A perfect fit starts with taking precise, and multiple, measurements. Don't just measure once and call it good. Trust me, openings are almost never perfectly square.

Here’s a quick checklist to make sure you’ve covered all your bases:

- Measure Height at Three Points: Check the height on the far left, dead center, and the far right of the opening. Always use the smallest of these three numbers.

- Measure Width at Three Points: Do the same thing for the width—measure at the top, middle, and bottom. Again, your magic number is the smallest one. This accounts for any weird warping or bulky baseboards.

- Confirm the Delivery Path: This is the one everyone forgets. Can you actually get the unit into your kitchen? Measure every doorway, hallway, and tight corner on the route from the delivery truck to its final home.

Proper ventilation is non-negotiable for the health of your equipment. Most manufacturers require at least 1-2 inches of clearance on the sides and back. This space allows for critical airflow and keeps the compressor from burning itself out.

Planning for Clearance and Utilities

Once you have your opening's dimensions locked down, it's time to think about the space around it. For a truly professional look, achieving a perfect installation often starts with properly templating countertops for a perfect fit to ensure every dimension lines up beautifully. This single step prevents ugly gaps and gives you that clean, built-in finish.

Next, think about the door. In a busy Los Angeles kitchen, will a swinging door block a high-traffic walkway or smash into another piece of equipment? In those tight spots, a drawer unit might be the smarter play.

And finally, locate your electrical outlets and plumbing lines before you click "buy." Make absolutely sure the refrigerator's cord and any water lines can easily reach their hookups. You don't want to rely on risky extension cords or call in a plumber for last-minute work. A little foresight here saves you from a massive headache on installation day.

Choosing Your Ideal Door and Drawer Configuration

Once you've nailed down the perfect external dimensions, it’s time to think about the inside. This is all about matching the unit's layout to the rhythm of your kitchen. The choice between doors and drawers isn't just about looks—it’s a critical decision that dictates how fast your crew can grab ingredients during a chaotic service.

This internal setup directly shapes the speed and flow of your entire operation. It doesn't matter if you're running a high-volume Los Angeles pizza joint or a tight-quarters food truck; the right configuration keeps your team moving smoothly and efficiently.

Solid Doors vs. Glass Doors

The most common setup you’ll see is one or more doors, but the type of door you pick needs to line up with how you’ll use it. Each style brings its own unique advantages to the table.

- Solid Doors: These are the champs of insulation. They’re best for back-of-house stations where you're storing bulk ingredients. Solid doors are fantastic at holding consistent temperatures, which helps keep your energy bills down.

- Glass Doors: Absolutely perfect for front-of-house or bar areas. A glass door gives your bartender a complete view of the beverage selection at a glance, speeding up service and making inventory checks a breeze without ever letting the cold air out.

Think about it: a busy Mexican restaurant in LA might use a solid-door unit on the main prep line for meats and cheeses. But behind the bar? They'll have a glass-door model to show off craft beers and sodas.

The Advantage of Drawers for Prep Lines

For a fast-paced prep station, drawers are a total game-changer. Instead of squatting down and digging through shelves, your line cooks can just pull out a drawer for immediate, top-down access to perfectly organized ingredient pans.

This setup is a massive efficiency boost, especially for certain kitchens:

- Pizza and Sandwich Shops: Drawers give you lightning-fast access to toppings and condiments, keeping the assembly line moving without a hitch.

- Taco Trucks and Prep Stations: Picture having all your salsas, onions, and cilantro neatly organized in pans, ready to go. Drawers make it happen, cutting down on wasted movement and cranking up output.

Choosing drawers over doors for a prep line isn't just a preference; it's a strategic move to reduce motion and increase speed. Every second saved by not having to search for an ingredient is a win during a dinner rush.

Specialized Units for Specific Tasks

Beyond your standard door and drawer models, you'll find specialized undercounter units built for very specific jobs. These purpose-built workhorses are designed to handle the unique demands of certain kitchen environments.

One of the most popular is the chef base, also known as a refrigerated equipment stand. These are heavy-duty units with refrigerated drawers and a reinforced stainless steel top tough enough to support hot equipment like griddles or charbroilers. This smart design puts cold storage directly under the cooking surface, creating an incredibly compact and efficient workstation.

Similarly, back bar coolers and kegerators are built from the ground up for beverage service. Their interiors are configured specifically to hold bottles, cans, or even full-sized kegs. To find the right fit for your operation, you can explore a wide variety of undercounter refrigerator options designed for every kind of Southern California restaurant or bar.

Common Questions About Undercounter Refrigerator Sizes

Even after you’ve done your homework, a few last-minute questions about undercounter refrigerator sizes can pop up. To help you nail down the perfect unit with total confidence, we’ve put together some quick, straightforward answers to the questions we hear most from L.A. restaurant and food truck owners.

What Is the Standard Height of an Undercounter Refrigerator?

You'll find that the vast majority of commercial undercounter refrigerators are built to a working height between 34 and 36 inches. This isn't a random number; it’s specifically designed so they can slide neatly under standard 36-inch commercial countertops, giving you that clean, built-in look every professional kitchen aims for.

How Much Clearance Do I Need Around My Refrigerator?

This is a big one. Proper ventilation is absolutely critical for keeping your unit from burning out. Most manufacturers will tell you to leave at least 1-2 inches of clearance on the sides and back, and sometimes a bit more on top, to let the air circulate. Always, always check the spec sheet for your specific model before you install it to prevent overheating and keep your warranty intact.

Neglecting proper clearance is one of the fastest ways to kill a compressor, especially in a hot Southern California kitchen. That little gap is what allows heat to escape, keeping your refrigerator running efficiently day in and day out.

Can I Put an Undercounter Refrigerator on Casters?

Absolutely, and we highly recommend it. Many commercial units either come with casters (wheels) or have the option to add them. This makes it a breeze to pull the unit out for deep cleaning underneath and behind it—a non-negotiable for passing health inspections. Just remember that casters will add a few inches to the total height, so make sure to account for that in your measurements.

Are Restaurant and Bar Units Different?

They might look similar on the outside, but their internal layouts are usually worlds apart. A kitchen prep unit is typically set up with shelves designed to hold standard food pans. A back bar unit, on the other hand, will often have notched shelving for wine bottles or wide-open space to accommodate kegs. You’ll also see a lot more glass doors on bar units—it’s all about showing off the product so bartenders and customers can see what’s available at a glance.

Ready to find the perfectly sized undercounter refrigerator for your Southern California business? At LA Restaurant Equipment, we offer a huge selection of new, warranty-backed equipment at warehouse-direct prices. Get fast, free shipping and flexible financing to outfit your kitchen without breaking the budget. Explore our collection online at https://larestaurantequipment.com and get your operation running smoothly.