Setting up a restaurant kitchen isn't just about buying a bunch of shiny new equipment. It's about designing the literal heart of your business, the engine that powers everything. A smart, well-planned layout directly fuels your speed, efficiency, and safety. This is true whether you're opening a packed Silver Lake pizzeria, a fast-paced Mexican spot in East LA, or a nimble food truck navigating the streets of Los Angeles.

Your success story starts with a solid blueprint, long before a single appliance is even considered.

Your Blueprint for a High-Performance LA Kitchen

Before you even think about equipment, you need a plan. A real plan. Think of your kitchen layout as the foundation of your restaurant's entire daily operation. Get it wrong, and you build in friction, slow down service, and risk expensive fines from the LA County health department.

But when you get it right? You create a seamless workflow, your staff is happier and more effective, and the customer’s experience is that much better.

The design process starts with a detailed floor plan. It’s not just about where the oven goes; it’s about how your team moves, communicates, and works together in that space. A classic mistake I see all the time is buying the gear first and then trying to shoehorn it into the space. That’s a recipe for disaster, leading to cramped walkways, poor station placement, and costly last-minute calls to the plumber and electrician.

Mapping Out Critical Kitchen Zones

First things first: break down your space into logical zones. Every zone has a job, and how you arrange them dictates the entire flow of your kitchen, from a box of produce coming in the back door to a finished plate heading out to a customer. This isn't just about being organized; it's about preventing cross-contamination and stopping your staff from running into each other all shift.

Here are the essential zones you need to map out:

- Receiving and Storage: This is where everything arrives. It needs to be near a back entrance and have your dry storage shelves, plus your walk-in cooler and freezer. Easy in, easy to store.

- Food Preparation: This is your main mise en place station. Think prep tables, sinks for washing produce, and space for chopping, mixing, and getting ingredients ready for the line.

- Cooking Line: The hot zone. This is the main event where your ranges, ovens, fryers, and grills live. The layout here has to be perfectly tailored to your menu.

- Service and Plating: The final checkpoint. You need space here for plating, adding garnishes, and holding finished dishes under heat lamps so they go out hot.

- Warewashing: The cleanup pit. Sinks, dishwashers, and drying racks belong here. You want it out of the way of food prep to avoid contamination but close enough that servers and cooks can drop off dirty dishes without a long trek.

A well-designed kitchen can boost a restaurant's efficiency by up to 20%. That’s a huge impact on your ticket times and, ultimately, your bottom line. The goal is a straight line for food: from receiving to prep to cook to plate. No backtracking, no chaos.

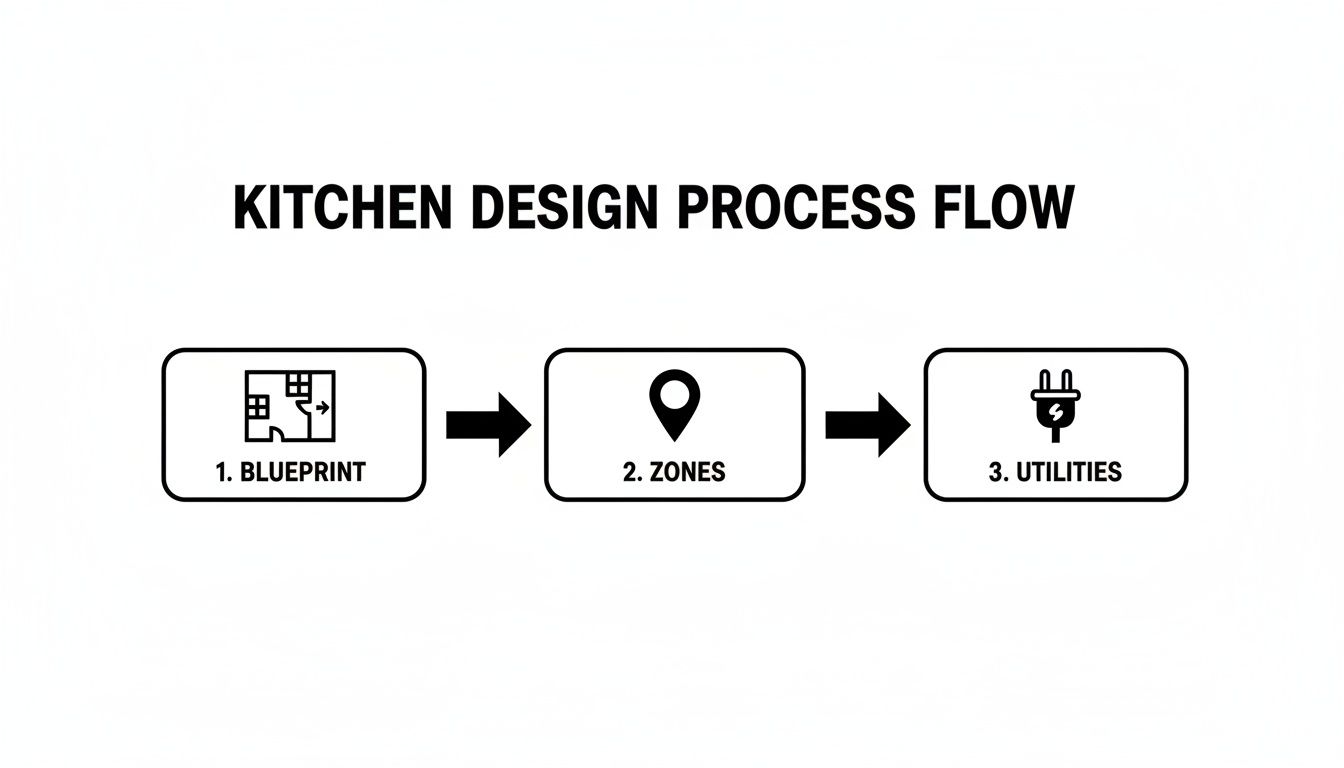

This simple flow chart really breaks it down. You start with the big picture—the blueprint—then you get specific with your zones, and finally, you layer in the technical stuff like utilities.

It’s a deliberate process. A great layout doesn’t happen by accident.

Planning Utilities and Code Compliance Early

Now for the part that trips up so many new owners: utilities. This is one of the most critical and easily overlooked steps. Your blueprint has to account for every single electrical, gas, and plumbing need for every piece of equipment.

A powerful convection oven needs a different electrical hookup than a refrigerator. A commercial gas range needs a properly sized gas line and a serious ventilation hood. You can't just guess.

Mapping all this out in the design phase will save you from incredibly expensive and time-consuming fixes down the road. You absolutely must work with licensed plumbers and electricians who know LA's commercial codes inside and out. Getting this right from day one not only saves you a ton of cash but it helps you sail through health and safety inspections without delays. That means you get your doors open, and start making money, that much sooner.

Designing Your Kitchen Workflow Station by Station

A great kitchen has a rhythm. It’s a carefully choreographed dance where every movement is purposeful, preventing the chaos that can absolutely tank a dinner rush. Now that you have a high-level blueprint, it's time to zoom in on the specific stations that bring that plan to life.

The goal here is simple: a linear, logical flow that moves ingredients from the delivery truck to a finished plate with zero backtracking. This station-by-station approach is fundamental to setting up a restaurant kitchen that’s built for speed and safety. By designing each zone with its specific function in mind, you create an environment where your team can work efficiently, avoiding collisions and frustrating bottlenecks.

Receiving and Storage: The Gateway to Quality

Everything starts at the back door. Your receiving and storage area is the first point of contact for every single ingredient that enters your restaurant. It needs to be organized, easily accessible, and designed to get products checked in and put away fast.

Picture a delivery truck arriving mid-service. You can't have staff weaving through the hot line with boxes of produce. The ideal setup places your receiving door directly next to your dry storage shelves and walk-in coolers or freezers. This simple adjacency minimizes travel time and reduces the risk of temperature abuse for perishable goods.

A busy Los Angeles pizza joint, for example, needs serious space here for bulky items like 50-pound bags of flour and cases of tomatoes, plus dedicated cooler space for cheese and meats. It’s the very first step in maintaining quality control.

Food Prep: Your Mise en Place Hub

Once ingredients are properly stored, they head to the food prep area. This is where the magic of mise en place happens—the washing, chopping, and portioning that sets your cooks up for a successful service. Critically, this station should be physically separate from both the raw receiving area and the hot cooking line to prevent cross-contamination.

Key equipment here includes:

- NSF-certified stainless steel work tables: These are non-porous, incredibly durable, and easy to sanitize. They're a non-negotiable for any commercial kitchen.

- Dedicated prep sinks: You’ll need separate sinks for washing produce versus thawing meat or washing hands. This is a big one for the LA health code.

- Undercounter refrigeration: Keeping prepped items like chopped vegetables or signature sauces within arm’s reach makes the entire kitchen run faster.

A Mexican food concept, for instance, would design this area with ample space for dicing onions, marinating meats, and pressing fresh tortillas—keeping everything organized and ready for the cooks.

The Cooking Line: The Hot Zone

This is the heart of your entire operation. The layout of your cooking line is dictated completely by your menu and concept. The goal is to arrange equipment in a logical sequence that mirrors how a dish is actually prepared. To nail an efficient culinary workflow, understanding a fundamental concept like the kitchen work triangle can provide a solid foundation for your layout.

Think about a food truck in Los Angeles where space is at an absolute premium. The line might be a compact arrangement: a griddle for searing, followed by a fryer, and then a small steam table for holding. Every piece of restaurant equipment has to be multi-functional and placed for maximum efficiency in a tight corridor.

A thoughtfully designed cooking line ensures a cook can pivot, not run, to access everything they need. This focus on economy of motion can reduce ticket times by 15-30% during peak hours.

Service, Plating, and Warewashing: The Final Steps

After a dish is cooked, it moves to the service and plating station. This area acts as the bridge between the back and front of the house. It needs space for final garnishes, heat lamps to keep food hot, and an organized system for servers to pick up orders without getting in the way.

Finally, there's the unsung hero: the warewashing station. It should be located near the dining room entrance so servers can drop off dirty dishes without trekking through the main cooking area. A proper setup must include a three-compartment sink for washing, rinsing, and sanitizing, alongside a high-temperature commercial dishwasher to handle the serious volume.

By breaking down your space into these five distinct zones, you can create a kitchen that not only functions but truly flows. This station-based approach is the key to building an efficient, safe, and productive engine for your restaurant.

Choosing the Right Cooking Equipment for Your Menu

The cooking line is the heart and soul of your kitchen. It's where the magic happens, where raw ingredients become the dishes your guests will be talking about for weeks. This is absolutely not the place to pinch pennies. Think of your cooking equipment as a direct investment in the quality, consistency, and speed of your entire operation.

I get it, the temptation to buy used equipment is strong, especially when you're just starting out and every dollar counts. But that path is filled with hidden risks. Imagine your main fryer giving up the ghost in the middle of a chaotic Friday night dinner rush. The money you thought you saved instantly vanishes in lost sales, furious customers, and the premium you'll pay for an emergency repair. New, warrantied equipment buys you reliability and, more importantly, peace of mind. Your ranges, fryers, griddles, and ovens are your workhorses—they need to be ready to perform, no questions asked.

When it comes down to it, your menu has to be the single driving force behind every equipment decision. The goal is a perfect match between the appliance's specs—from its physical size to its BTU output—and the specific dishes you plan to create.

Tailoring Equipment to Your LA Concept

Los Angeles is a city of a thousand different culinary dreams, and each one demands a unique set of tools. A cookie-cutter approach to outfitting your cook line just won't cut it here.

Let's look at a few classic LA restaurant types.

For a Mexican restaurant that prides itself on authentic flavor, a high-powered charbroiler is non-negotiable. It’s the only way to get that perfect, smoky sear on carne asada. You'd pair that with a multi-burner range for simmering complex moles and a big, flat griddle (or plancha) for everything from handmade tortillas to gooey quesadillas.

Now, picture a buzzing Los Angeles food truck. Space is the ultimate luxury, so every piece of gear has to earn its spot. High-output, quick-recovery fryers are a must for slinging crispy fries or churros without making people wait. A combination griddle/charbroiler unit can give you menu flexibility in a tiny footprint, and undercounter refrigeration is your best friend for keeping ingredients fresh and accessible.

And what about a classic Los Angeles pizza joint? It has its own specialized needs, and the undisputed star of that show is the oven. A specialized deck oven, famous for producing that perfectly crisp crust, is the traditional weapon of choice. Investing in a high-capacity model means you can keep up with the dinner rush, turning out consistently beautiful pizzas one after another.

The Financial Sense Behind Smart Equipment Choices

Investing in the right cooking equipment is one of the biggest financial moves you’ll make. This isn't just about the upfront price tag; it's about long-term value and operational efficiency. The right choices can lead to big savings on utilities and labor, directly boosting your bottom line.

Smart equipment selection goes way beyond the purchase price. Investing in ENERGY STAR-rated models can slash your kitchen's energy bills by 15-25%. That's a significant saving that adds up, month after month.

This financial reality is a big deal across the industry. When setting up a restaurant kitchen, smart investments in cooking equipment are paramount, which is why it commands a massive 31% share of all U.S. foodservice demand. Full-service restaurants and hotels, which make up 72% of the global foodservice equipment market, depend on heavy-duty ranges, fryers, and ovens to handle their volume. It's clear that successful operators make these decisions very carefully.

To give you a better idea of what you might need, this table breaks down the core cooking line essentials for these popular LA restaurant concepts.

Essential Cooking Equipment by Restaurant Type

Here’s a quick look at the core cooking equipment needed for some of the most popular restaurant concepts you'll find around Los Angeles. Notice how the "Key Feature" is always tied directly to what's on the menu.

| Restaurant Type | Essential Equipment | Key Feature to Look For |

|---|---|---|

| Mexican Restaurant | Multi-Burner Range, Charbroiler, Griddle (Plancha) | High BTU output for rapid heating and authentic searing. |

| Los Angeles Food Truck | High-Recovery Fryer, Compact Griddle, Undercounter Fridge | Small footprint with multi-functional capabilities to save space. |

| Los Angeles Pizza | Deck Oven, Dough Mixer, Pizza Prep Table | Consistent high-temperature performance for perfect crusts. |

This breakdown really shows how your menu creates your shopping list. To dive deeper and make sure you haven't missed anything, check out our comprehensive commercial kitchen equipment checklist. It covers everything from cooking and refrigeration to storage and warewashing.

By lining up your equipment with your culinary vision from the start, you ensure that every dollar you spend is on a tool that will actively drive quality, efficiency, and profitability from day one.

Mastering Cold Storage and Food Preparation Areas

While the sizzle of the cooking line gets all the attention, the real workhorses of any efficient kitchen are its cold storage and food preparation areas. I’ve seen it time and time again: these zones are the absolute backbone of food safety, ingredient quality, and the speed of your entire operation.

Getting this right isn't just about buying a few coolers. It’s about building a seamless system that keeps your food safe and lets your team work at peak efficiency.

Think of your cold storage as the bank vault for your inventory. If you mismanage it, you're looking at spoilage, waste, and a direct hit to your bottom line. A well-organized system, from bulk storage all the way to line-ready ingredients, is fundamental to setting up a restaurant kitchen that actually makes money.

Strategic Refrigeration for Maximum Efficiency

Your refrigeration strategy has to be built around your specific concept and workflow. This is never a one-size-fits-all deal. The whole point is to place cold storage exactly where it’s needed to cut down on wasted steps and crank up the speed during service.

A Los Angeles pizza joint, for example, is dead in the water without a specialized pizza prep table. These units are brilliant—they combine refrigerated rails on top for toppings like cheese and pepperoni with refrigerated cabinets below for dough trays. This setup lets one person build pizzas at an incredible pace without ever leaving their station.

By the same token, a bustling Los Angeles food truck or a high-volume sandwich shop would get a massive productivity boost from a dedicated sandwich prep station. It works on the same principle, keeping meats, cheeses, and condiments chilled and within arm's reach. What used to be a multi-step process becomes a fluid, assembly-line motion.

Beyond the specialty units, every single kitchen needs a mix of these essentials:

- Walk-in Coolers and Freezers: This is non-negotiable for bulk storage of produce, meat, and dairy. Good shelving and a strict first-in, first-out (FIFO) system are your best friends here.

- Reach-in Refrigerators: Placed strategically near your prep and cooking lines, these hold the portioned ingredients you need for the current service.

- Undercounter Refrigeration: These compact powerhouses slide right under prep tables, giving you immediate access to high-use items and keeping your staff out of the main walk-in during a rush.

The Foundation of Food Prep: Stainless Steel

The food prep area is where your menu truly comes to life. This zone demands uncompromising cleanliness and durability, which is why NSF-certified stainless steel work tables are the industry standard. This is not a place to cut corners.

Stainless steel is non-porous, so it won’t harbor bacteria, and it's tough enough to take the daily beating of chopping, pounding, and constant sanitizing. When you're picking out tables, look at different setups. Some come with built-in sinks for washing produce, while others have undershelves for storing containers and small equipment, keeping your work surfaces clear and organized.

For a Mexican food concept in LA, this area would be set up for dicing mountains of onions and cilantro, marinating meats, and prepping salsas. Having multiple, dedicated prep surfaces is crucial for preventing cross-contamination between raw meats and fresh veggies—something health inspectors look for immediately.

A well-organized prep area with strategically placed refrigeration can reduce prep time by up to 30%. That efficiency gain means your kitchen can handle a higher volume of orders without adding labor costs, which flows directly to your profitability.

Ultimately, the synergy between your cold storage and prep stations sets the pace for your entire kitchen. By investing in the right equipment and laying it out logically, you create an environment where food stays fresh, safe, and ready for action. This is the foundation of a high-functioning kitchen, ensuring you deliver quality and consistency from the moment an ingredient walks in the door to the second a finished dish hits the pass.

Navigating LA's Kitchen Installation and Permitting Process

Alright, you’ve nailed down the layout and picked out all your gear. Now for the moment of truth: bringing your commercial kitchen to life. This is where blueprints and invoices turn into a real, working space. It’s all about installing equipment, hooking up utilities, and getting the green light from the Los Angeles County Department of Public Health.

Think of this final stretch as pure execution and compliance. Having a solid plan here is the difference between a smooth launch and getting bogged down by delays and surprise costs. Get this part right, and you’ll have a kitchen that’s not just efficient, but fully legal and ready for day one.

Coordinating Installation and Professional Services

First up: managing the delivery and install of your big-ticket items. This takes some serious coordination with your suppliers and contractors. My advice? Stagger the deliveries. You definitely don’t want your walk-in cooler showing up while plumbers are trying to run new lines through that exact spot.

And let’s be clear, this phase is not a DIY project. You absolutely must hire licensed pros for every utility connection. The risks of cutting corners on gas or electrical work are massive, from frying expensive equipment to creating serious fire hazards. When you're in the thick of it, finding a qualified commercial electrical contractor is a non-negotiable step. These experts make sure everything is wired to code, which is one of the first things a health inspector will look for.

Key installations you'll need professionals for include:

- Gas Lines: A licensed plumber needs to handle this to ensure every oven, range, and fryer is connected safely and tested for leaks.

- Electrical Work: A commercial electrician will set up the correct voltage and dedicated circuits your heavy-duty equipment demands.

- Plumbing: This covers everything from the three-compartment sink and dishwashers to floor drains and the all-important grease trap.

Ventilation and Fire Safety Compliance

Two systems you cannot mess around with are ventilation and fire suppression. In Los Angeles, these aren't just good ideas—they are strict legal requirements enforced by both the health department and the fire marshal.

Your commercial hood has to be the right size for the cooking line below it. Its whole job is to pull heat, smoke, and greasy air out of your kitchen. This system works hand-in-hand with an automated fire suppression system, which is designed to knock down grease fires instantly. Both need to be installed and certified by a specialized company.

Don't treat fire suppression as just another box to check. A properly installed and maintained system is your number one defense against a fire that could end your business. Inspectors are meticulous—they will check the certification tags and test the system.

Passing the Final Health Inspection

The final health inspection is the last hurdle standing between you and opening day. An inspector from the LA County Department of Public Health will walk through your entire restaurant, but they’ll spend most of their time in the kitchen. They’re there to confirm that your setup meets every single health and safety code.

Here's what they're looking for:

- Food Temperatures: Are your refrigerators and freezers holding at the correct temperatures? They will check.

- Sanitation: Do you have a proper three-compartment sink, correctly placed handwashing sinks, and a certified dishwasher?

- Cross-Contamination Prevention: Are there clear, separate areas and tools for handling raw and ready-to-eat foods?

- General Condition: Are the floors, walls, and ceilings smooth, non-absorbent, and easy to keep clean?

Passing this inspection on your first try saves an incredible amount of time, money, and stress. It’s the official thumbs-up that your kitchen is safe and ready for the public. The whole process can seem daunting, but a well-planned project makes it much smoother. For a look at the entire journey, check out our guide on https://larestaurantequipment.com/blogs/los-angeles-restaurants/how-to-start-a-restaurant.

Common Questions on Setting Up Your LA Kitchen

When you're deep in the weeds of planning a new restaurant, it's easy to get overwhelmed. You're not alone. I've worked with countless restaurateurs across Los Angeles and Orange County, and I've found that many of the same questions come up time and time again.

Let's dive into some of the most common concerns and get you some straight-up, practical answers.

What’s a Realistic Budget for Kitchen Equipment?

This is the million-dollar question, isn't it? The honest-to-goodness answer is that it completely depends on your concept. A brand-new, fully-loaded kitchen for a small restaurant can run you anywhere from $100,000 to over $300,000.

A food truck will naturally be on the lower end of that scale. On the other hand, if you're opening a large-scale pizzeria with specialized deck ovens, you’ll be pushing that higher number. Your biggest ticket items will always be the cooking line and your refrigeration units.

Where I see a lot of people make a critical mistake is underbudgeting for ventilation and fire suppression systems. These are non-negotiable from a safety and code perspective, and the costs can be surprisingly high.

A good rule of thumb I share with clients is to set aside 30-40% of your total equipment budget for the cooking line. Plan for another 20-25% for refrigeration and 10-15% for ventilation and fire safety. The rest will get eaten up by prep tables, storage, and your warewashing station.

Should I Buy New or Used Equipment?

I get it, the upfront cost of used equipment is incredibly tempting. But for the heart of your kitchen—the core cooking line and refrigeration—I almost always advise clients to buy new. You want a warranty.

Think about it: the risk of a used fryer going down during a slammed Friday night service, or a second-hand walk-in cooler failing overnight and spoiling thousands of dollars in inventory... it just isn't worth the initial savings.

Now, for less critical items like stainless steel prep tables, shelving, or dunnage racks? Used can be a fantastic way to stretch your budget. But for the machinery that makes you money day in and day out, the reliability and peace of mind that come with a new, warrantied unit are invaluable.

Can I Run Multiple Concepts from One Kitchen?

Yes, absolutely. This is the whole idea behind the "ghost kitchen" or "virtual kitchen" model, and it's exploding in dense markets like Los Angeles. You can operate several delivery-only brands from a single, well-designed kitchen.

For instance, your primary Mexican restaurant's kitchen could easily support a delivery-only wing concept on the side. The key is planning your kitchen layout and equipment to handle the different workflows and added volume without creating total chaos. It's a brilliant strategy to maximize revenue without the crushing expense of leasing another property.

No matter what questions pop up, remember that the right equipment is the foundation of your restaurant's success. LA Restaurant Equipment is here to provide Southern California's restaurant owners with reliable, new, and energy-efficient gear at warehouse-direct prices. We help you build your dream kitchen without the headaches and risks that come with used equipment.

Ready to get started? Explore your options and start building your kitchen today at https://larestaurantequipment.com.