Think of an undercounter refrigerator as the unsung hero of your kitchen line. When it fits just right, everything flows smoothly. A unit that’s too big or too small can throw a wrench in your whole operation. That's why nailing the fridge under counter size from the get-go is a game-changer for any busy Los Angeles kitchen, whether you're running a pizzeria, a food truck, or a popular Mexican restaurant.

Most standard commercial units will fall into a predictable range: typically 24 to 72 inches wide, with a consistent counter-height of 34 to 36 inches and a depth somewhere between 24 and 32 inches. Investing in a new, warrantied piece of equipment means you're getting reliability right out of the box—a smart play for any foodservice business.

Your Quick Guide to Undercounter Fridge Sizes

Choosing the right undercounter refrigeration is a foundational step in designing an efficient commercial kitchen. It doesn't matter if you're running a bustling L.A. pizza joint, a trendy food truck, or a classic Mexican restaurant—these compact units are absolute workhorses, keeping crucial ingredients perfectly chilled and always within arm's reach.

You can see their value in the numbers. The global market for undercounter refrigerators hit a staggering USD 36.93 billion in 2022 and is projected to climb to USD 51.89 billion by 2030. That kind of growth tells you just how essential these space-saving, efficient cooling solutions have become in professional kitchens everywhere.

Standard Undercounter Fridge Dimensions at a Glance

To help you start mapping out your space, we've put together a quick reference table. Think of this as a starting blueprint to help you visualize how different units will slot into your kitchen's layout.

| Appliance Type | Common Widths (Inches) | Standard Height (Inches) | Typical Depth (Inches) |

|---|---|---|---|

| Undercounter Fridge | 24" - 72" | 34" - 36" | 24" - 32" |

| Undercounter Freezer | 24" - 48" | 34" - 36" | 24" - 32" |

| Chef Base | 36" - 84" | 20" - 26" | 30" - 34" |

| Back Bar Cooler | 24" - 90" | 34" - 37" | 24" - 28" |

This table gives you a great ballpark idea, but don't stop here.

Remember, these dimensions are a starting point. Always, always check the manufacturer's spec sheet before you buy. Little things like casters, door handles, and required ventilation clearance can make all the difference between a perfect fit and a major headache.

Picking the right fridge is just one piece of the puzzle. To get a complete picture of everything your kitchen needs to succeed, take a look at our guide on building a commercial kitchen equipment checklist. It’ll help you cover all your bases, from the cooking line to cold storage, ensuring your culinary team has a fully functional and efficient space to work their magic.

How to Measure Your Kitchen Space Accurately

Getting the perfect undercounter fridge doesn't start when you hit "add to cart." It starts way before that, with a tape measure and a good, hard look at the space you're working with. Think of it like making a blueprint for your kitchen—a tiny mistake here can cause a massive headache during installation, especially in a busy LA kitchen where every second counts.

This isn't just about getting the basic width, height, and depth. You have to look for the little things that can trip you up. We're talking about baseboards that stick out, floors that aren't perfectly level (meaning the unit's feet will need adjusting), or even the small lip of a countertop that hangs over the edge. A truly accurate measurement accounts for all these quirks right from the get-go.

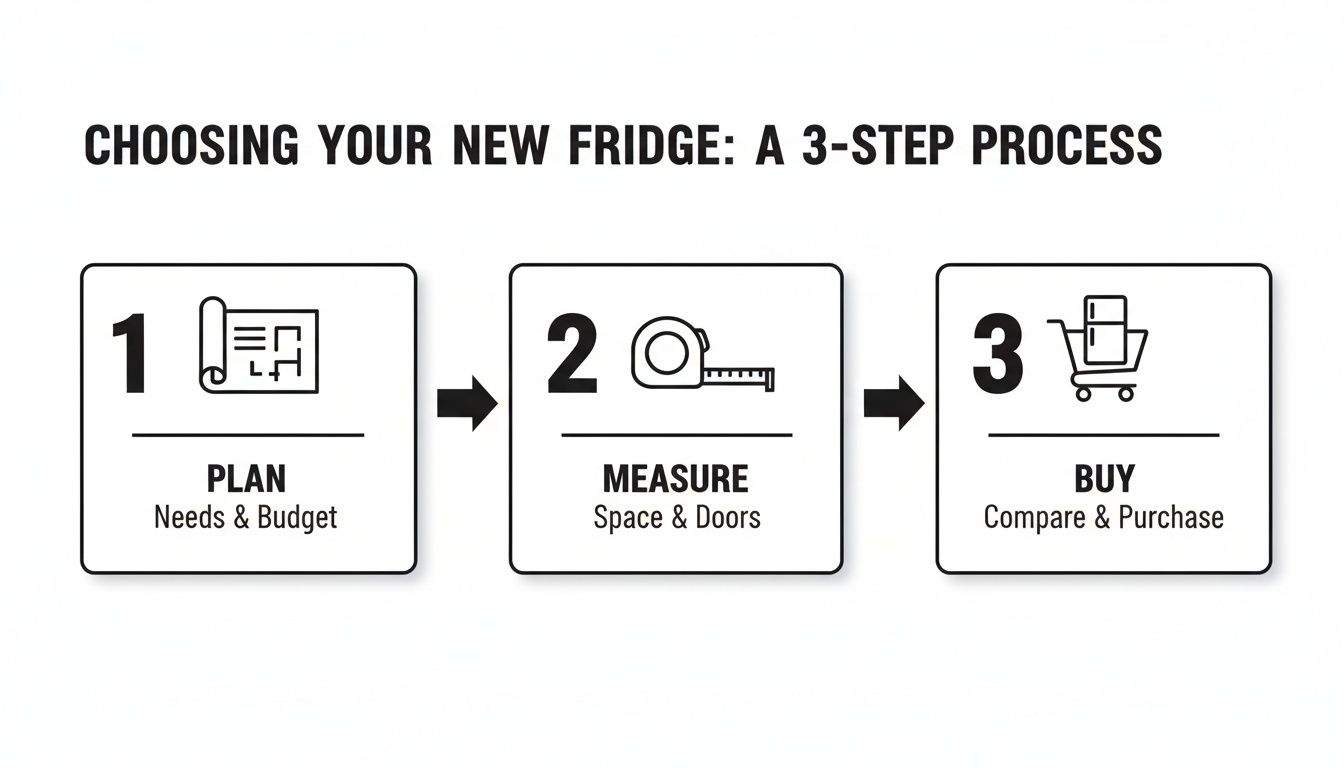

This little guide breaks down the simple but crucial steps to take before you even think about buying a new unit.

As you can see, planning and measuring come first. They're the foundation for making a smart purchase.

The Critical Role of Ventilation

The single most important measurement—besides the unit's actual dimensions—is what we call "breathing room." Commercial refrigerators are workhorses, and their compressors kick off a lot of heat. If that heat gets trapped, the unit has to work way harder, driving up your energy bill and eventually causing parts to fail.

You'll generally run into two types of ventilation setups:

- Front-Venting Models: These are your best bet for true built-in installations. Air gets pulled in and pushed out through a grille on the front of the unit. That means you can slide them in snug against walls and right next to other equipment without worrying.

- Rear/Side-Venting Models: You usually see this on freestanding units. They need at least 2-4 inches of clear space on the back and sides to get rid of heat properly. Jamming one of these into a tight, enclosed cabinet is asking for trouble.

Always, always check the manufacturer's spec sheet for their specific clearance requirements. It’s the easiest thing you can do to protect your investment and keep your fridge running efficiently for years.

One last thing—don't forget to measure the entire delivery path. That means from your restaurant’s front door, down any hallways, and around those tight corners in the kitchen. A fridge that fits perfectly under the counter is totally useless if you can't physically get it there. Before you settle on a unit, think about how it fits into the bigger picture of your kitchen's flow. For some great tips on that, check out this guide on planning a kitchen remodel.

Choosing Between Built-In and Freestanding Models

When you're picking out an undercounter fridge, one of the first big decisions you'll face is whether to go with a built-in or a freestanding model. It's a choice that comes down to more than just looks.

Think of a built-in unit like a custom-tailored suit—it’s made to slide perfectly into your cabinetry for that clean, seamless look. A freestanding model, on the other hand, is more like a trusty utility cart; you can place it just about anywhere you have space.

The real game-changer between these two is ventilation. It’s all about how the unit breathes.

Understanding Ventilation and Why It Matters

Built-in units are cleverly designed with front-facing vents, usually right on the bottom grille. This means they pull in cool air and push out hot air from the front, allowing you to install them flush against walls and squeeze them right next to other equipment without any risk of overheating.

Freestanding models are different. They typically vent from the back and sides, which means they need a few inches of "breathing room" all around to get rid of heat properly. If you shove a rear-venting model into a tight, enclosed cabinet, you’re setting it up for failure. The trapped heat forces the compressor to work overtime, leading to sky-high energy bills and, eventually, a dead machine.

This is a huge deal in high-traffic Los Angeles spots like a packed pizzeria or a tiny food truck, where every single inch of floor space counts. It’s no surprise that space-saving designs are booming; undercounter beverage refrigerators are on track to grab 36% of the total revenue in the global beverage refrigeration market by 2025. That growth is powered almost entirely by front-venting units that slot perfectly into tight bar setups.

Choosing the right ventilation style isn't just a suggestion—it's absolutely essential for protecting your investment. A correctly installed unit will run like a champ for years, but one that can't breathe might fail in just a few months, leaving you with costly downtime and spoiled product.

For a closer look at some seriously reliable equipment, check out our guide on the best commercial refrigerator brands. You’ll find models that fit both your space and your performance needs. At the end of the day, matching the fridge under counter size and type to your kitchen’s layout is the key to making sure your new equipment works as hard as you do from day one.

Matching Your Fridge Size to Your Menu and Workflow

Choosing the right undercounter fridge isn't just about finding a box that fits a gap in your kitchen line. You've got to think bigger. The best choice is a unit that actually supports your menu and makes your team's life easier, becoming an active tool for efficiency, not just a place to keep things cold. The real goal is to match the appliance to the job, so every ingredient is exactly where it needs to be, right when the cook needs it.

Think of it this way: a compact 24-inch undercounter fridge is the perfect sidekick for a busy Los Angeles pizza joint's drink station. It takes up almost no space but keeps beverages perfectly chilled and literally an arm's length away. That small footprint prevents a traffic jam behind the counter and keeps the line moving during that critical dinner rush.

Tailoring Equipment to Culinary Needs

As your menu and volume grow, your equipment strategy has to evolve, too. A bustling food truck slinging burgers would get a huge boost from a 48-inch chef base. This is a brilliant two-for-one piece of equipment. It gives you a sturdy, heat-resistant countertop for your griddle while putting refrigerated drawers right below for patties, bacon, and cheese. That setup creates a powerful, self-contained workstation that just cranks out orders.

A busy Mexican restaurant, on the other hand, needs a completely different setup. A 60-inch or 72-inch refrigerated prep table becomes the heart of the whole operation. It provides a massive cutting board surface for building tacos and burritos, with cold wells on top for salsas, pico de gallo, and shredded lettuce. The refrigerated cabinets below store all the backup ingredients, meaning fewer trips to the walk-in and more time serving customers.

If you want to see how top-tier commercial kitchens are designed with a specific menu in mind, it's worth checking out projects like the Masa Restaurant Upfit.

Doors vs. Drawers: Which is Right for You?

The debate between doors and drawers is all about workflow. It’s a critical decision because each one serves a very different purpose in a fast-paced kitchen.

- Door Models: These are your go-to for bulky items. Think big Cambro containers of sauce, cases of drinks, or tall bottles. They give you flexible shelving and are usually the more budget-friendly pick for general cold storage.

- Drawer Models: Drawers are the undisputed champions of organization and speed. They’re designed to perfectly hold standard-sized food pans (like sixth-pans or ninth-pans) full of prepped ingredients. A chef can pull open a drawer and instantly see and grab everything they need, which is an absolute game-changer for high-volume stations like pizzerias and sandwich shops.

Choosing between doors and drawers isn't about which is better overall, but which is better for a specific station. A smartly designed kitchen will almost always use a mix of both—doors for the bulk stuff and drawers for the grab-and-go prep ingredients.

At the end of the day, picking the right undercounter fridge size and style is a strategic move. When you really analyze your menu, pinpoint those high-traffic prep stations, and match the equipment to the task, you’re not just buying an appliance. You're investing in a tool that boosts productivity, saves your staff countless steps, and ultimately, helps your bottom line.

Installation Tips for Peak Performance and Safety

You've done the hard part—you measured the space and picked the perfect fridge under counter size. Now it’s time to nail the installation. Getting these last few steps right is absolutely critical for your unit's performance and long life, helping you sidestep those common mistakes that lead to expensive repairs and frustrating downtime for your LA spot.

Before the delivery truck even pulls up, you should run through a few pre-installation checks. This bit of prep is the difference between a smooth, painless setup and a day full of headaches. Think of it as mise en place for your new equipment; getting everything ready beforehand guarantees a perfect final result.

Your Pre-Installation Checklist

To make sure everything goes off without a hitch, walk through these key steps. They tackle the most common installation pitfalls we see that can cause problems for a new undercounter unit.

- Verify Electrical Requirements: Pull out the spec sheet and check the unit’s voltage and amperage. You absolutely need a dedicated, grounded outlet that matches these numbers. Trying to run it on an overloaded circuit isn’t just a fire hazard—it's a great way to fry the refrigerator's compressor.

- Confirm Floor Support: Is the floor where it's going perfectly level? A wobbly fridge will put constant strain on the door hinges and prevent it from sealing properly. You also need to be sure the floor can handle the unit’s weight when it’s fully stocked to avoid any nasty surprises down the line.

- Plan the Door Swing: Think about which way the door needs to open. You don't want it creating a bottleneck or swinging out into a busy walkway. That’s a surefire way to disrupt your kitchen’s flow and create a safety risk for your team.

Proper installation isn’t just about making the unit fit. It’s about creating a safe and efficient environment. Taking ten minutes to check these details can save you hours of headaches and protect your investment.

The demand for these compact, efficient units just keeps growing, especially in crowded urban kitchens. The global undercounter freezers market was valued at USD 880.17 million in 2024 and is expected to hit USD 1,204.58 million by 2032. For independent restaurant owners in Los Angeles, this just confirms what we already know: undercounter units are a smart, strategic investment. You can find more insights about the growth of the undercounter freezer market on Maximize Market Research.

When your new unit arrives, give it a thorough inspection for any shipping damage before you sign off on the delivery. Once you have it in place, let it run empty for at least 24 hours. This gives the internal temperature time to stabilize, ensuring your ingredients are stored safely from the moment you load it up. For more ways to get the most out of your gear, check out our guide on energy-efficient commercial refrigerators.

Got Questions About Undercounter Fridges? We Have Answers.

Running a restaurant in Los Angeles means every inch of space counts. When you're trying to find the perfect fridge under counter size, a lot of questions can come up. This is the final rundown, tackling the most common things we hear from operators just like you. Getting these answers straight helps you invest with confidence.

Think of this as your final checklist. We'll clear up everything from ventilation needs to why a commercial-grade unit is the only real choice for a pro kitchen. It all comes down to choosing equipment that can handle the relentless pace of our industry.

What Is the Standard Height of a Commercial Undercounter Fridge?

Most commercial undercounter refrigerators are built to a standard height of 34 to 36 inches. This isn't a random number—it’s the magic measurement that lets them slide perfectly under standard 36-inch commercial countertops.

This design standard creates that clean, built-in look you see in professional kitchens and bars all over Southern California. It’s all about a smooth workflow. But—and this is a big but—always measure your own counter height and double-check the fridge's spec sheet. You also need to factor in the adjustable feet or casters, which can add or subtract a crucial fraction of an inch.

How Much Breathing Room Does an Undercounter Fridge Need?

This all boils down to one simple thing: where the unit breathes. The ventilation system is its lifeline, and suffocating it is a recipe for disaster.

- Front-Venting Models: These are the champs of tight spaces. They pull air in and push it out through a grille on the front, meaning you can build them in with almost zero clearance on the sides or back.

- Rear/Side-Venting Models: More common for freestanding units, these guys need space. You have to leave at least 2-4 inches of open air around the back and sides so the compressor doesn't cook itself.

Blocking the airflow is easily one of the top reasons we see for equipment failing way too early. Do yourself a favor and read the manufacturer's manual. Following their specific clearance rules is the best way to protect your investment.

Can I Just Use a Residential Undercounter Fridge in My Restaurant?

Look, we get the temptation. A residential unit might look like a way to save a few bucks upfront, but it's almost always a costly mistake in the long run. A busy L.A. pizza joint or a bustling food truck puts a beating on equipment that home appliances were never designed for.

Commercial units are in a different league. They have powerful compressors, are built from tough materials like stainless steel, and, most importantly, are NSF-certified to keep the health inspector happy. They're engineered to be opened and closed hundreds of times a day while holding safe temperatures in a sweltering kitchen. A residential fridge will burn out, void its own warranty, and could get you in trouble with health codes. It's a gamble that just isn't worth taking.

What’s the Difference Between an Undercounter Refrigerator and a Chef Base?

While they both live under the counter, they have completely different jobs. An undercounter refrigerator is your all-purpose cold storage—a workhorse with doors or drawers for holding everything from sauces and dressings to prepped produce.

A chef base, on the other hand, is a specialized beast. It’s also called a refrigerated equipment stand for a reason. Its top is a heavy-duty, reinforced slab of steel designed to hold a 500-pound griddle or charbroiler. Below, refrigerated drawers give the line cook instant access to burger patties, cheese, or fish right where the action is. A chef base is all about combining cold storage and an equipment stand into one seamless unit to make the cooking line faster and more efficient.

Finding the right equipment shouldn't feel like a puzzle. At LA Restaurant Equipment, we have a massive selection of new, warrantied undercounter refrigeration ready to go for any commercial kitchen in Southern California. Check out our full lineup of commercial kitchen solutions and find the perfect fit for your business today.