Picking the right commercial refrigerator for your Los Angeles restaurant isn’t a one-size-fits-all deal. What works for a sprawling Mexican restaurant in East LA is going to be wildly different from the setup a nimble food truck needs over in Venice Beach. A smart investment in restaurant equipment smooths out your kitchen workflow, keeps your inventory safe, and helps you get a handle on those energy bills. This guide will walk you through making a solid, long-term decision for your Southern California operation.

Choosing Your Commercial Refrigerator in Southern California

Deciding on your refrigeration is easily one of the most critical choices you'll make as a foodservice operator in Los Angeles or Orange County. It’s about so much more than just keeping things cold. You’re protecting thousands of dollars in food inventory, staying compliant with health codes, and managing your operational costs.

The right unit becomes the quiet, dependable workhorse of your kitchen, whether you're slinging pizzas at a high-volume Los Angeles pizza spot or crafting specialty items in one of the many Los Angeles food trucks. This decision touches everything, from how smoothly your line operates to the size of your monthly utility bill. It's not just about the sticker price; a huge part of this is reducing total cost of ownership over the life of the machine, which means thinking about energy use, maintenance, and how long it’s built to last. Choosing well from the start is how you avoid those frantic calls for emergency repairs down the road.

Understanding the Market and Your Needs

The demand for quality commercial refrigeration is booming, and you can see it in the numbers. Globally, the industry was valued at around USD 85.6 billion in 2024 and is expected to nearly double by 2034. That growth is all about businesses like yours needing top-notch, efficient cooling. It pays to get familiar with the commercial refrigeration equipment market trends to see where things are headed.

Before you even start looking at models, you need to get crystal clear on your own needs. What’s the main job this refrigerator will be doing in your kitchen day in and day out?

| Refrigerator Type | Primary Use Case (LA Example) | Key Advantage |

|---|---|---|

| Reach-In | Bulk storage for a busy Mexican food restaurant kitchen | High capacity and easy access for kitchen staff |

| Undercounter | Under-the-counter storage for a compact LA food truck | Maximizes limited space, keeps ingredients at hand |

| Prep Table | Sandwich or salad assembly line in a quick-service cafe | Combines refrigerated storage with a sanitary workspace |

| Display Merchandiser | Grab-and-go drinks at a convenience store | Boosts impulse sales with excellent product visibility |

Comparing Commercial Refrigerator Types for LA Kitchens

Picking out the best commercial refrigerator for a Los Angeles kitchen is about more than just a spec sheet. You have to picture how a piece of equipment will actually fit into your daily grind. A slammed Mexican food kitchen in East LA has totally different needs than a tiny food truck cruising through the OC, and the right fridge can make or break your service speed.

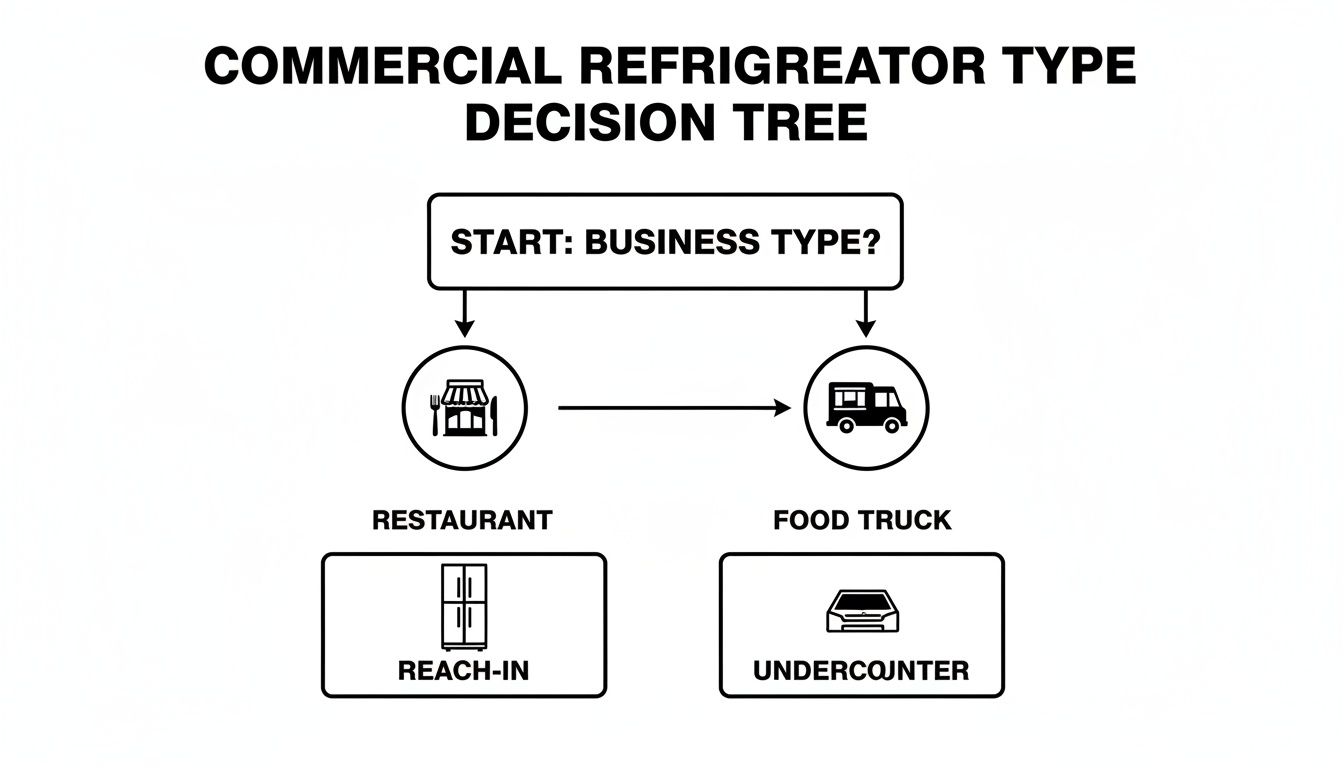

Every single business has its own unique puzzle to solve. This decision tree is a great way to see how different restaurant models naturally lead to certain refrigeration choices.

As you can see, it all starts with your business. That directly points you to the gear that will actually work for your space and your team.

To make this even clearer, let's break down how these different types of refrigerators fit into real-world Southern California foodservice operations. This table gives you a quick snapshot.

Commercial Refrigerator Use Case Comparison

| Refrigerator Type | Ideal For (LA/OC Use Case) | Primary Benefit | Space Consideration |

|---|---|---|---|

| Reach-In | High-volume restaurants, pizzerias, catering kitchens | Bulk storage capacity | Requires significant floor space |

| Undercounter | Food trucks, coffee shops, bars, tight prep stations | Space optimization | Fits under existing counters |

| Prep Table | Sandwich shops, salad bars, pizzerias | Streamlined assembly | Combines workspace and storage |

| Chef Base | Busy hot lines in restaurants and diners | Efficiency at the cook station | Supports cooking equipment on top |

Now, let's dig a little deeper into what makes each one tick.

Reach-In Refrigerators: The Bulk Storage Workhorse

For any high-volume spot, from a bustling Los Angeles pizza joint to a packed Mexican restaurant, the reach-in refrigerator is the king of bulk storage. Period. These units come in one, two, or three-door models and are built to hold massive amounts of prepped food—think tubs of pizza sauce, pans of carne asada, you name it—right where your line cooks can grab it.

The main advantage here is raw capacity. A three-door reach-in holds an incredible amount of product, which means fewer trips to the walk-in and a smoother service during that chaotic dinner rush. The trade-off? They have a big footprint, so you need to plan your space carefully, especially in those notoriously tight LA kitchens.

Undercounter Refrigerators: Maximizing Every Square Inch

Now, picture one of the many Los Angeles food trucks. Space isn't just a consideration; it's everything. Every single inch has to pull its weight. This is exactly where undercounter refrigerators come in and save the day. They tuck right under your prep counters, giving you instant access to your most-used ingredients without eating up an ounce of precious floor space.

Their compact design is a perfect match for the close quarters of a mobile kitchen. You can create a super-efficient layout where everything is just an arm's length away. Sure, you don't get the massive storage of a reach-in, but the ability to turn dead space into functional cold storage is a total game-changer for food trucks, pop-ups, and cafes.

The core difference isn't just size; it's about workflow integration. A reach-in serves a static, high-volume line, while an undercounter unit supports a dynamic, space-constrained environment where every inch counts.

Refrigerated Prep Tables: The Assembly Line Specialist

Refrigerated prep tables are the heart and soul of any business built around assembly, like sandwich shops or salad bars. These specialized workhorses combine a refrigerated base for all your ingredient pans with a sanitary cutting board right on top. It’s a completely self-contained workstation.

Think about a busy downtown LA lunch spot. Your team can stand in one spot, pulling fresh veggies and meats from the cold wells below while building sandwiches right on the integrated workspace. This design slashes unnecessary movement, streamlines the entire process, and makes you faster. These units are purpose-built, and for certain menus, they’re absolutely essential.

Chef Bases: Fueling the Hot Line

Finally, we have chef bases, sometimes called low-boy refrigerators. These are designed specifically to support a high-speed cooking line. They have a heavy-duty, heat-resistant top that can hold equipment like griddles or charbroilers, while the refrigerated drawers underneath store your raw proteins and prepped veggies.

This setup is clutch for any fast-paced kitchen where cooks need ingredients right now at the cooking station. By putting cold storage directly under the heat, a chef base eliminates wasted steps and keeps the workflow fluid. It’s the ultimate piece of gear for keeping the line firing on all cylinders without missing a beat.

Diving Into the Key Technical Specs

So you've figured out what type of refrigerator you need, whether it's a big reach-in for your pizzeria or a compact undercounter unit for a food truck. Now comes the real work: digging into the technical details of your restaurant equipment. These specs are what separate a workhorse from a headache in a high-pressure Los Angeles kitchen.

Getting past the shiny stainless steel exterior is where you find a machine’s true character. Understanding these specs helps you make a choice based on real-world performance, not just the price tag. You'll see exactly how one model’s features will impact everything from your kitchen's flow to your monthly utility bills.

Compressor Placement: Top-Mount vs. Bottom-Mount

The compressor is the engine of your refrigerator, and where it sits makes a huge difference, especially in a hot, busy kitchen. Commercial units almost always come in two flavors: top-mount and bottom-mount.

- Top-Mount Compressors: These are fantastic for dry storage areas or kitchens where flour, dust, and other floor debris are common. With the compressor up high, it pulls in cleaner, cooler air from above, which helps it run more efficiently and keeps it from getting clogged.

- Bottom-Mount Compressors: In a sizzling LA kitchen, this is usually the way to go. Heat rises, so a compressor placed near the floor is operating in a cooler environment. It's also a small but meaningful ergonomic victory for your team—the bottom shelves are easier to reach without all the bending.

The real decider here is your environment. A top-mount unit is a lifesaver in a bakery battling floor dust, while a bottom-mount is typically the smarter, more efficient pick for a scorching hot prep line.

Capacity and Temperature Range

Nailing down the right capacity, measured in cubic feet, is absolutely critical. You need enough room for your inventory during peak times without cramming everything in. Overcrowding kills airflow and forces the unit to work way harder than it should. A solid rule of thumb is to calculate your maximum inventory needs and then add a 20% buffer for growth or those big catering events.

Temperature is just as non-negotiable. Most commercial refrigerators are built to hold food safely between 33°F and 41°F. That range is the sweet spot for keeping everything from prepped produce for a taco shop serving Mexican food to fresh dough for a pizzeria at its best. Always double-check that the unit you're eyeing can hold these temps without flinching, even when the doors are constantly opening during a dinner rush.

Why an ENERGY STAR Rating is More Than Just a Sticker

That little blue ENERGY STAR sticker is a promise of serious operational savings. These models aren't just slightly better; they are engineered from the ground up with high-efficiency compressors, superior insulation, and modern components that slash electricity use.

For any Southern California business, where energy costs are no joke, this is a massive deal. We've actually put together a detailed guide on energy-efficient commercial refrigerators that shows how the savings stack up. Choosing an ENERGY STAR model is one of the smartest financial moves you can make—it's an investment that literally pays you back every single month.

Your Essential Pre-Purchase Checklist

Choosing the right commercial refrigerator is a huge decision, and a few last-minute checks can save you from some serious headaches down the line. Before you pull the trigger, run through this checklist to make sure the unit is a perfect fit for your Los Angeles or Orange County kitchen—whether you're running a pizza joint, a food truck, or a classic Mexican restaurant.

Trust me, skipping these steps can lead to delivery nightmares or, worse, finding out your brand-new equipment isn't even compatible with your setup. A quick, thorough review now is your best defense against operational chaos later.

Space and Electrical Verification

First things first: grab a measuring tape. Don't just measure the spot where the refrigerator will live. You need to measure every single doorway, hallway, and tight corner it has to navigate on delivery day. In older L.A. buildings, those narrow passages can be a nasty surprise.

Next up, double-check your electrical setup. You need to confirm your kitchen’s outlets match the refrigerator's voltage and amperage needs, which you'll find on the unit's spec sheet. An electrical mismatch can cause performance problems or force you into expensive rewiring.

Compliance and Certification

Health code compliance is something you just can't mess with. Make sure the refrigerator you’re looking at is NSF certified. This is a hard requirement for most health departments here in Southern California, and it’s your guarantee that the unit is designed for safe food storage and is easy to keep clean.

You can find our complete guide to outfitting your kitchen in this commercial kitchen equipment checklist.

New vs Used Equipment Considerations

A used refrigerator might look like a great deal, but it often comes with a whole lot of risk. You're dealing with a questionable history and zero warranty protection. New restaurant equipment, like the Atosa units we carry, gives you rock-solid reliability right out of the box, backed by a manufacturer's warranty that protects your investment.

Opting for a new, warrantied refrigerator eliminates the gamble of used equipment. It ensures you receive a reliable, efficient, and compliant unit that won't disrupt your business with unexpected breakdowns.

Ventilation and Installation Logistics

Finally, think about ventilation. Your refrigerator's condenser needs plenty of airflow to work efficiently and avoid burning out, which is a huge deal in our warm Southern California climate. Make sure there’s enough clearance around the unit—usually a few inches on all sides is enough.

You should also confirm the delivery and installation details. With LA Restaurant Equipment, you get fast, free local shipping, so your unit will get to you quickly. Planning for a smooth installation means your new refrigerator will be up and running without delay, getting your kitchen back to full speed that much faster.

A Practical Maintenance Schedule to Protect Your Investment

Getting the right commercial refrigerator for your Los Angeles business is a big deal, but protecting that investment is where the real work starts. I can't stress this enough: proactive maintenance isn't just a good idea, it's non-negotiable for staying profitable. It stops those nightmare breakdowns, keeps your food safe, and puts a lid on soaring energy costs. A simple, consistent schedule will keep your Atosa unit humming along for years.

I've put this plan together specifically for busy operators in LA and Orange County, breaking down the essential tasks into simple, repeatable actions. Stick with it, and you'll get more life out of your equipment and dodge the brutal cost of emergency repairs.

Daily and Weekly Checks

It’s the small habits that make the biggest difference for a healthy refrigerator. Weaving these quick checks into your daily and weekly routine is the best way to catch minor issues before they turn into major headaches.

Daily Tasks (2 minutes):

- Wipe Down Surfaces: Clean any spills on the interior and exterior. This prevents grime buildup and keeps things sanitary.

- Monitor Temperatures: Glance at the internal thermometer to make sure it's holding a safe temperature, ideally between 33°F and 41°F.

Weekly Tasks (10 minutes):

- Clean Gaskets: Just wipe down the door gaskets with a cloth and some warm, soapy water to clear out any debris. A clean seal is crucial because it stops cold air from leaking out.

- Inspect for Tears: While you're cleaning, give the gaskets a quick once-over for any rips or tears that could be compromising that seal.

A torn or dirty gasket forces your compressor to work overtime, which drives up your energy consumption and causes premature wear and tear. Honestly, this simple weekly check is one of the most effective ways to lower your utility bills.

Monthly Deep Cleaning

Once a month, it's time to give some attention to the heart of your refrigeration system: the condenser coil. If you’re in a dusty kitchen environment—think pizzerias or any spot near a busy freeway—this task becomes even more critical for keeping things efficient. Of course, this kind of regular care is vital for all your key systems. For a wider view on keeping everything running smoothly, it's worth reading up on commercial equipment servicing best practices.

Cleaning the condenser coils is absolutely essential. When you let dust and grease build up, it acts like an insulator on the coils. This forces the compressor to run longer and hotter, which leads directly to higher energy bills and, eventually, a total breakdown.

The push for efficiency is real; energy-efficient models already make up about 40% of sales and are on track to hit 50% by 2025. Keeping your coils clean is how you ensure your unit actually operates at that peak efficiency, saving you real money.

For an even more detailed guide, check out our article on commercial kitchen equipment maintenance for some extra tips.

Common Questions We Hear About Commercial Refrigerators

When you're running a restaurant in Los Angeles or Orange County, you don't have time for guesswork. You need straight answers to make a smart investment. Here are some of the most frequent questions we get from local restaurant, food truck, and café owners just like you.

Top-Mount vs. Bottom-Mount Compressors

In a sweltering SoCal kitchen, the choice is almost always a bottom-mount compressor. Think about it: heat rises. A bottom-mount unit pulls in the cooler air hovering near the floor, so it doesn't have to work as hard to keep things chilly inside. That means better energy efficiency and less wear and tear on your machine.

Now, a top-mount compressor has its place. If you're in a bakery with flour dust everywhere, a top-mount keeps the coils from getting clogged. But for the vast majority of hot restaurant kitchens, the bottom-mount design is the clear winner for performance and a longer lifespan.

Do I Need a Standard Reach-In or a Specialized Unit?

This all comes down to your kitchen's flow. A reach-in refrigerator is your workhorse for bulk storage. It’s perfect for holding big pans of prepped ingredients, whether you're running a busy taqueria serving Mexican food or a high-volume catering operation.

On the other hand, a chef base or prep table is all about optimizing your workflow. A chef base puts refrigerated drawers right under your griddle or range, giving you instant access to ingredients on the hot line. A prep table is a lifesaver for streamlining sandwich or Los Angeles pizza assembly. So, choose a reach-in for sheer capacity, but go with a specialized unit to boost speed and efficiency at specific stations.

Is It Better to Buy New or Used Equipment?

The biggest advantage of buying a new refrigerator is the manufacturer's warranty. Simple as that. It protects your investment from surprise breakdowns and expensive repairs, giving you some much-needed peace of mind. Plus, a new unit guarantees you're getting an efficient machine that meets all current health codes right out of the box.

Used restaurant equipment might seem cheaper upfront, but it’s a gamble. You're dealing with an unknown history, no warranty, and likely higher energy bills from older, less efficient parts.

Can My Business Get Financing?

Yes, absolutely. We know that for Los Angeles food trucks, small cafes, and brand-new restaurants, managing cash flow is critical. That's why LA Restaurant Equipment offers flexible financing options.

Financing makes it possible to get the new, reliable equipment you need with manageable monthly payments. This way, you can hold onto your cash for all the other things your business needs to thrive.

Get the Right Equipment from a Trusted Local Partner

Choosing the best commercial refrigerator isn't just about specs—it's about finding the right workhorse for your kitchen. Whether you're running a high-volume Mexican food restaurant, a nimble food truck, or a classic Los Angeles pizza joint, the right unit protects your inventory and keeps your workflow smooth. We've walked through the different types, the key features to look for, and how to keep it all running, so you can make a smart, lasting investment.

Now, it's time to get your kitchen set up for success. Here at LA Restaurant Equipment, we specialize in helping Southern California's foodservice operators get their hands on new, warranty-backed Atosa refrigeration. You get the day-in, day-out reliability your business needs without taking a gamble on used equipment.

Partnering with a local supplier means more than just a transaction; it means getting expert guidance and support tailored to the unique demands of the Southern California market.

We keep things simple with warehouse-direct pricing and have flexible financing options to make top-tier restaurant equipment more accessible. Our local warehouse in Brea, CA, means we can offer fast and free shipping, with most of our orders arriving in just 1-2 business days. Let our team help you find the perfect unit to elevate your operation.

Ready to upgrade your kitchen? Browse our full catalog of new commercial refrigeration at LA Restaurant Equipment and get the performance and value your business deserves. https://larestaurantequipment.com