Choosing the right equipment for food truck kitchens is where the rubber meets the road. This is about more than just buying appliances; you're engineering a high-speed, mobile production line designed to smash the lunch rush. The whole game is about maximizing every single square inch for efficiency, safety, and output, especially in the competitive Los Angeles food truck scene.

Your Blueprint For A High-Performance Food Truck Kitchen

A killer food truck doesn't just appear. It starts way before you serve a single customer, with a smart plan for the heart of your operation—the kitchen. The decisions you make here directly control your speed, what you can put on your menu, and ultimately, your profits.

A rookie mistake I see all the time is buying equipment before the menu is locked in. The gear you'd need for a Los Angeles Pizza truck—a compact deck oven, a refrigerated prep rail—is completely different from what a Mexican Food concept needs with its massive flat-top griddle and steam table. Let your menu drive the equipment list, never the other way around.

Mapping Your Kitchen Workflow

Before you even glance at a specific model or brand, you have to map your workflow. Seriously, close your eyes and visualize an order's entire journey, from the ticket printing to the moment you hand that beautiful finished product to a customer. A logical layout stops your staff from doing the "kitchen dance," constantly bumping into each other. That chaos is a major cause of slowdowns and accidents in such a tight space.

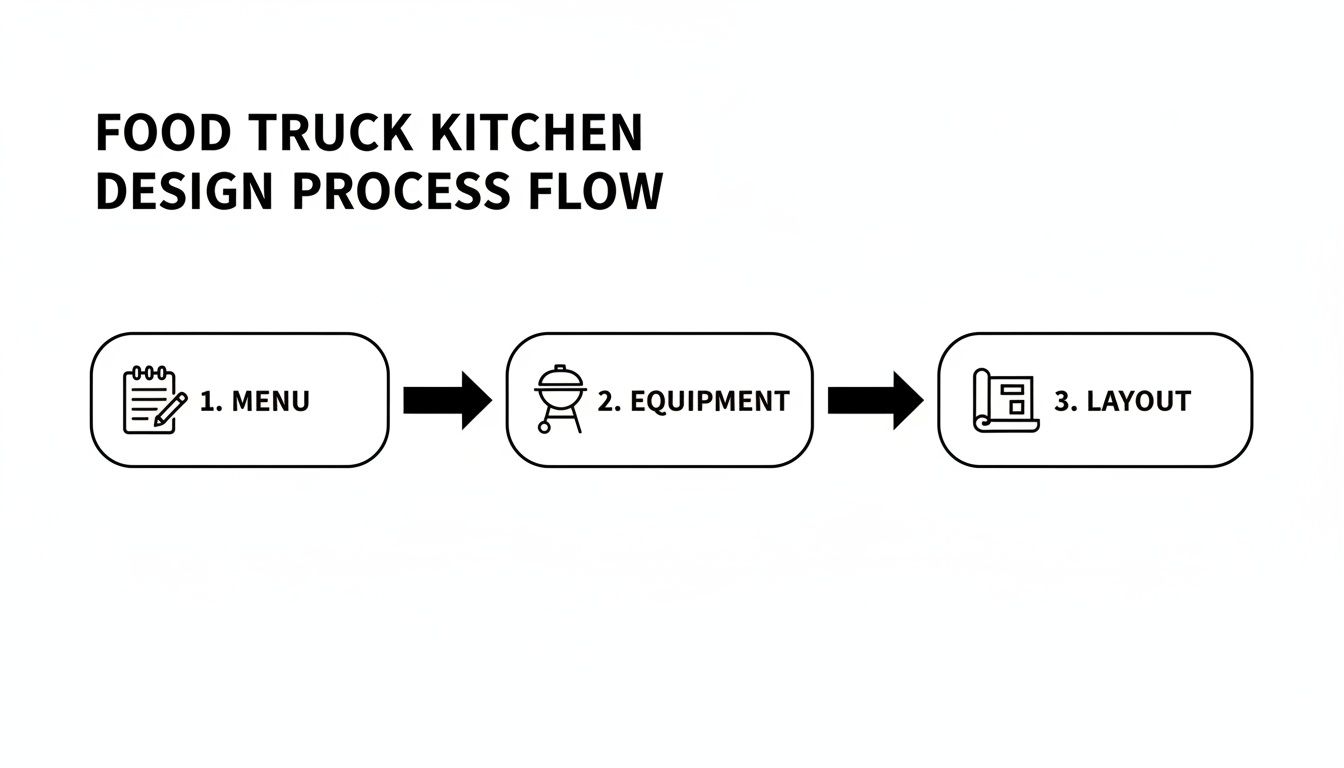

This flow chart nails the process. It’s all about a logical progression from your concept to the physical layout.

This simple flow—Menu → Equipment → Layout—is your mantra. Each step builds on the last, creating a kitchen that just works.

This is also the moment you have to get real about your budget. Commercial restaurant equipment is a huge chunk of your startup cost. The global market for this gear is projected to jump by about USD 41.8 billion between 2025 and 2029. For a food truck, that often means 20–40% of your initial budget goes straight to cooking and ventilation systems, with refrigeration and prep stations eating up another 15–30%. You can discover more insights about the commercial kitchen equipment market on technavio.com.

The goal isn't just to cram equipment into a truck; it's to create a system. A well-designed kitchen slashes ticket times, cuts down on food waste, and makes life less stressful for your team. That means you serve more people, faster, and grow your business.

To help you get started, here's a quick rundown of the major equipment categories you'll absolutely need to consider.

Essential Food Truck Kitchen Equipment Categories At A Glance

| Equipment Category | Primary Function | Key Considerations |

|---|---|---|

| Cooking Line | The core of your menu production. | Match appliances (griddles, fryers, ovens) directly to your menu items. |

| Refrigeration | Safe cold storage for ingredients. | Undercounter units save space; consider both refrigerators and freezers. |

| Prep Stations | Space for chopping, mixing, and assembly. | Stainless steel is mandatory; look for integrated sinks and storage. |

| Ventilation | Exhausting smoke, heat, and grease. | Must comply with local fire codes; includes hood and fire suppression. |

| Sinks & Sanitation | Handwashing, dishwashing, and food prep. | Health codes require a 3-compartment sink plus a separate handwashing sink. |

| Power & Utilities | Running all your equipment. | Generator size, propane tank capacity, and clean/grey water tanks. |

Each of these categories is a world of its own, but understanding how they fit together is the first step to building a kitchen that will make you money from day one.

Designing A Kitchen Layout That Actually Works

Before you even think about dropping cash on all that shiny new equipment for food truck kitchens, you have to stop and design your space. Seriously. The layout isn't just about making things fit; it's the invisible engine that determines how fast you can serve, how safe your crew is, and just how chaotic that lunch rush feels. A great layout is your secret weapon.

Your average food truck kitchen is unbelievably tight, usually somewhere between 120 to 200 square feet. That tiny footprint means every single inch has to count. You can't just take a standard restaurant kitchen design and shrink it—that's a recipe for bottlenecks, safety issues, and a whole lot of wasted motion.

The best way to think about your layout is as a physical map of your menu. A taco truck in Los Angeles is going to need a long, flat-top griddle and a steam table right next to a cold prep station for all the toppings. A mobile pizzeria, on the other hand, will be built around a huge pizza prep table directly across from a compact deck oven to keep the workflow tight.

Creating Efficient Kitchen Zones

The most successful food trucks all rely on a zoning strategy. It’s a simple concept: create dedicated areas for specific tasks. This keeps your team moving smoothly and helps prevent cross-contamination. A logical flow gets rid of that awkward "kitchen dance" where everyone is constantly bumping into each other.

- Hot Line Zone: This is the heart of the operation where the actual cooking happens. Group your griddle, fryers, and ovens together, all tucked under your main ventilation hood. The cook should be able to reach everything they need without taking more than a step or two.

- Cold Prep & Assembly Zone: This is home to your undercounter refrigerators and refrigerated prep tables. It’s where salads get tossed, sandwiches are built, and final garnishes are added—well away from the intense heat of the cooking line.

- Sanitation & Cleaning Zone: This is non-negotiable and required by law. It includes your three-compartment sink and a separate handwashing station. You’ll want to place this area away from any food prep zones to stay compliant and keep things hygienic.

When you zone your kitchen correctly, an order moves in a straight, logical line—from preparation to cooking to the service window. This simple change can dramatically cut down on wasted steps and shave precious seconds off your ticket times.

Your kitchen's flow has to feel natural. If your cook has to walk across the entire truck to grab cheese from the fridge after dropping a burger on the griddle, your layout is broken. Fix it on paper before it costs you real money during a rush.

Visualizing Your Space Before You Build

Once you’ve mapped out your zones, it's time to bring it to life. Don't just guess. Use painter's tape on the floor of your garage or fire up a free online design tool to create a to-scale drawing of your truck's interior.

Make little cutouts for each piece of equipment—your fryer, your prep table, your sinks—and move them around. Can you open the refrigerator door all the way without blocking the main walkway? Is there enough clearance behind the hot line for your cook to work safely? Figuring this out now will save you from massive headaches and expensive mistakes down the road. For a deeper dive into this crucial step, you can learn more about commercial kitchen layout design in our detailed guide.

Trust me, this planning phase is the single most important investment you'll make. A well-designed layout makes every piece of equipment you buy more effective, keeps your team sane, and makes your business more profitable from the moment you slide open that service window.

Alright, let’s get to the fun part—the heart and soul of your food truck kitchen. We’re talking about the heavy-duty gear that will cook your food and keep it fresh. This is easily the biggest and most critical investment you'll make, so it's all about striking a smart balance between your culinary vision and the hard reality of limited space.

Your menu is the only blueprint that matters here. Every single appliance has to earn its keep by directly supporting the food you plan to serve. A classic L.A. smash burger truck lives and dies by its flat-top griddle. A Mexican Food truck? You'll need that griddle, plus a good multi-well steam table for holding all your delicious proteins and sides. Dreaming of serving up authentic Los Angeles Pizza? A compact deck oven isn't just nice to have; it's non-negotiable. It’s simple: don’t waste an inch of space or a watt of power on a fryer if you're not selling french fries.

Matching Your Menu To The Right Cooking Equipment

The link between your food and your hardware is direct and unforgiving. Make the wrong call, and you're looking at slow service, frustrated customers, and wasted potential. Let's break down how common menu concepts dictate the primary cooking equipment you absolutely need to nail your service.

Here's a quick cheat sheet to get you started:

| Menu Type | Primary Cooking Equipment | Best For | Space And Power Impact |

|---|---|---|---|

| Burgers, Tacos, Breakfast | Flat-Top Griddle | High-volume, versatile cooking for multiple items at once. | High. A large griddle consumes significant space and propane/gas. |

| Pizza, Baked Goods | Compact Deck or Convection Oven | Consistent, high-heat cooking for baking and roasting. | High. Requires dedicated space and significant electrical or gas draw. |

| French Fries, Fried Chicken | Countertop or Floor Fryer | Specialized for producing crispy, deep-fried menu items. | Medium. Countertop models save space but have lower output. |

| Sandwiches, Paninis | Panini Press / Induction Cooktop | Quick, efficient heating and toasting for assembled items. | Low. These units are compact and generally power-efficient. |

Choosing the right primary cooking unit is just the beginning. To make sure you've covered all your bases, from prep tools to sanitation, you should review our comprehensive commercial kitchen equipment checklist. It's an invaluable resource to ensure nothing crucial falls through the cracks.

The Unsung Hero: Refrigeration

While the sizzling grill gets all the attention, your refrigeration is the silent backbone of your entire operation. Period. Without solid, reliable cold storage, you're risking food safety violations, devastating product loss, and a health inspector shutting you down on the spot. In a food truck, you can't just cram in the biggest fridge you can find—you need smart, space-saving solutions that work with your layout.

This is where undercounter refrigerators and freezers prove their worth time and time again. They slide right under your prep counters, keeping ingredients right where you need them without eating up precious floor space. Another absolute game-changer is the refrigerated prep table. These brilliant units combine a chilled ingredient rail on top with cold storage cabinets below, creating a powerful, all-in-one station for building sandwiches, salads, or tacos with lightning speed.

Your refrigeration isn't just a cold box; it's your food safety insurance policy. Skimping here is one of the most dangerous mistakes a new food truck operator can make. Invest in new, reliable, NSF-certified units with warranties—the peace of mind is worth every penny.

Figuring out the right size for your refrigeration is a classic food truck puzzle. For the mid-sized trucks that dominate the scene—making up over 51% of the U.S. market—squeezing in enough cold storage can feel like a game of Tetris. It's not uncommon for undercounter units and prep tables to eat up 10–25% of the vehicle’s floor plan and an equally hefty 15–25% of its power budget.

Sizing Your Cold Storage Correctly

So, how much do you actually need? A good place to start is by estimating your peak service volume. You need to figure out the total amount of perishable ingredients required to get through your busiest day without a mid-service panic run to your commissary kitchen.

Let's get practical:

- Burger Truck: How many pounds of ground beef, packs of cheese, and bins of lettuce and tomato will you fly through during a lunch rush?

- Mexican Food Truck: Think in terms of hotel pans. How many pans of carne asada, pollo, and carnitas do you need ready to go? What about all your toppings like salsa, onions, and cilantro?

- Los Angeles Pizza Truck: Count your dough balls, blocks of mozzarella, and containers of sauce. How many pies will you be slinging on your best day?

Your mission is to have enough onboard cold storage to operate self-sufficiently for an entire service. My advice? Once you have your number, choose equipment that's slightly larger than your estimate. This gives you a buffer for growth and prevents the nightmare scenario of running out of a key ingredient when you have a line of hungry customers. This kind of careful planning ensures your cooking and refrigeration gear work together as a seamless, money-making machine.

Powering Your Operation With The Right Support Systems

Your shiny cooking line and refrigerators might get all the attention, but it's the support systems—the unsung heroes—that actually make it all work. A food truck is basically a self-sufficient kitchen on wheels. Without dependable power, water, and ventilation, even the fanciest equipment for food truck kitchens is just dead weight. These systems are non-negotiable, both for day-to-day operations and for staying on the right side of the law.

Think of your power source as the heart of your truck. It pumps life into everything, from your undercounter freezer to your POS system. Most operators go with a commercial generator, which gives you the freedom to set up shop anywhere, anytime. The other option, shore power, means you need a direct electrical hookup, which really limits you to specific event sites or your commissary.

Sizing Your Generator Correctly

Picking the right generator is absolutely critical. If it’s too small, you'll be tripping breakers constantly during a lunch rush, which can damage your expensive appliances and shut you down completely. You’ve got to calculate your total electrical load to avoid this nightmare.

First, list every single piece of electrical equipment and find its wattage requirement—it's usually on a nameplate. Add up the "running watts" for all the gear that will be on at the same time. Here's the pro tip: you also have to account for the "starting watts" of anything with a motor, like refrigerators. They need a big jolt of power to kick on.

Your generator's "running watts" capacity needs to be at least 20% higher than your peak load calculation. That buffer keeps you from redlining the generator and ensures you have steady, reliable power right when you need it most.

Water And Sanitation Systems

Next up, plumbing. Health departments are incredibly strict about this, and for good reason. Your truck must have a fully self-contained water system. That means:

- Fresh Water Tank: This holds all the clean water for cooking, cleaning, and handwashing. The size you'll need will depend on your menu and local health codes.

- Grey Water Tank: This is where all the wastewater from your sinks goes. Critically, this tank must be at least 15% larger than your freshwater tank to prevent any nasty overflows.

- Three-Compartment Sink: This is mandatory for properly washing, rinsing, and sanitizing your dishes and utensils. No getting around it.

- Separate Handwashing Sink: An absolute requirement for your staff. It has to have hot and cold running water, soap, and paper towels right there.

These aren't just suggestions from a blog post; they're legal requirements. A health inspector will be looking for this exact setup, and cutting corners here is a guaranteed way to fail an inspection.

Ventilation And Fire Safety

Finally, let’s talk about the system that keeps your team safe and prevents your truck from becoming a fire hazard: ventilation and fire suppression. When you're cooking with commercial equipment in such a tight space, the heat, smoke, and grease can get dangerous fast. A commercial-grade hood vent isn't optional—it's essential.

Your hood system has to be big enough to cover all your cooking appliances, from the flat-top griddle to the deep fryer. It works by sucking all that greasy air through filters and shooting it outside. Just as important is the built-in fire suppression system, which is designed to automatically douse a flare-up with fire-retardant chemicals.

As the U.S. food truck market keeps growing—with projections hitting USD 1.09 billion by 2025—manufacturers are making it easier for new operators. Many now offer compliance-ready packages that bundle the cooking equipment, ventilation, refrigeration, and power systems together. This is a huge help, giving you certified, turnkey sets that simplify the build-out and reduce headaches with regulators. You can explore the full kitchen trailers market report on futuremarketinsights.com.

For more tips on keeping your power usage in check, have a look at our guide on choosing energy-efficient commercial refrigerators.

Sourcing Your Equipment Without Breaking The Bank

You’ve got the perfect layout mapped out and a wish list of gleaming new equipment. Awesome. Now for the hard part: getting all that gear into your truck without completely blowing your startup budget. This is where smart sourcing becomes your best friend, turning that dream kitchen into a reality you can actually afford.

Before you even think about swiping a credit card, your first job is to become an expert on your local regulations. Here in Los Angeles, for example, the Health Department and Fire Department have incredibly specific rules about the equipment for food truck kitchens. Buying a used flat-top that seems like a steal is a classic rookie mistake—if it's not up to code, it's a guaranteed fail during inspection, and you'll be out of that money.

The Non-Negotiable World Of Compliance

Trust me, navigating the rulebook isn't just about avoiding a few fines; it's about whether your truck can legally open for business. The absolute first thing you need to look for on any piece of equipment is its NSF certification.

- What is NSF? NSF International is the independent gatekeeper for public health and safety. They test and certify that equipment meets strict standards.

- Why does it matter? That little NSF mark is the first thing a health inspector looks for. It’s a universal sign that your gear is made from safe materials, is designed to be cleaned easily, and won’t contaminate your food.

- The Bottom Line: No NSF sticker often means no permit. It's that simple. You'll be forced to replace brand-new (to you) equipment, which is a painful and expensive lesson.

This is especially critical for your cooking line and all your refrigeration. On top of that, fire codes will have their own set of demands for your ventilation hood and fire suppression system. Don't guess. Pick up the phone and call your local health and fire departments before you start shopping.

Smart Budgeting: New vs. Used Equipment

Ah, the great debate: should you buy new or used? Used equipment looks so tempting with those low price tags, but it’s a gamble. You’re rolling the dice with no warranty, a much shorter lifespan, and the constant fear of a breakdown in the middle of a dinner rush.

New equipment, on the other hand, is an investment in peace of mind. That brand-new, warranty-backed undercounter refrigerator or deep fryer is your insurance policy against surprise repair bills. Plus, modern units are almost always more energy-efficient, which means real savings on your generator fuel costs, day in and day out.

A used prep table or shelving unit can be a great way to save a few bucks. But when it comes to the heart of your kitchen—the stuff that cooks and cools—always invest in new, warranty-backed equipment. It's one of the smartest moves you can make for the long-term health of your business.

A hybrid approach is often the smartest play. Splurge on new for the mission-critical items that will shut you down if they fail. For the simpler, non-mechanical gear like stainless steel work tables or sinks, a quality used piece can be a fantastic find.

Finding The Right Equipment Partner

Where you get your equipment is just as critical as what you get. Sure, you can scroll through online marketplaces, but they offer zero expert guidance. A specialized restaurant equipment supplier is more than a seller; they’re a partner.

A good supplier gets the unique challenges of a mobile kitchen. They know the space constraints and can point you to the right-sized, fully compliant equipment for your menu, whether you’re outfitting a Mexican Food truck or a mobile Los Angeles Pizza operation.

For food truck owners in Southern California, this is a huge advantage. You can get fast, free shipping from a local hub like Brea, meaning your equipment often arrives in just a day or two. That speed is crucial when you’re trying to get your truck built and out on the road making money. Better yet, reputable suppliers offer flexible financing options, letting you get top-of-the-line, reliable gear for a manageable monthly payment. It’s the best way to protect your cash flow while building a kitchen that’s designed to last.

Your Top Food Truck Equipment Questions, Answered

Once you've got your menu nailed down and a rough layout in mind, the real-world questions start popping up. Outfitting a food truck kitchen is full of little details that can make or break your business. Let's tackle some of the most common—and critical—questions I hear from aspiring owners. Getting these right from the start will save you a world of headaches later on.

What’s the Single Most Important Piece of Equipment in a Food Truck?

It's not the griddle. It's not the fryer. The undisputed champion, the one thing your entire business hinges on, is your power source. Usually, this means a high-quality, quiet commercial generator.

Think about it: without a steady stream of electricity, every single expensive appliance you bought is just a heavy, useless metal box. A cheap, undersized generator is a business killer, plain and simple. It’ll constantly trip breakers during your busiest lunch rush, potentially frying the sensitive compressors in your refrigerators or crashing your POS system. Every light, every fan, every single transaction depends on that power.

Investing in a properly sized, durable generator isn't just another line item on your budget; it's the foundation of your entire operation.

Should I Buy New or Used Equipment for My Food Truck Kitchen?

This is the classic tug-of-war between budget and reliability that every new operator deals with. Going with used equipment can slash your startup costs, which is always tempting. But that path is loaded with risks. You're looking at no warranty, a much higher chance of things breaking down mid-service, and the real possibility of failing your Los Angeles health inspection.

New equipment, on the other hand, buys you peace of mind. You get manufacturer warranties, better energy efficiency (which means you'll spend less on generator fuel), and guaranteed compliance right out of the box with NSF-certified units.

A smart hybrid approach is often the best way to go. Splurge on new equipment for the absolute must-haves—your generator, refrigeration, and main cooking line. For simpler things like stainless steel prep tables or sinks, a quality used piece can be a fantastic way to save cash.

But whatever you do, always have a qualified technician inspect any used gas or refrigerated equipment before a single dollar changes hands.

How Do I Figure Out How Much Power My Truck Needs?

Calculating your power needs is not something you can guess on. Get this wrong, and you’re signing up for constant shutdowns and fried equipment. The good news is, the process is pretty straightforward.

- Make a List: Write down every single thing that plugs in, from your big convection oven down to your phone charger. Everything.

- Find the Nameplate: On each item, find the manufacturer's nameplate. This will tell you its power requirements in either watts (W) or amps (A) and volts (V).

- Do the Math: If an item only lists amps, use this simple formula: Watts = Volts x Amps. Most U.S. commercial gear runs on 120V or 240V.

- Add It All Up: Now, sum the total peak wattage for everything that might run at the same time. This is your absolute maximum load.

Here's the key: choose a generator with a continuous "running watts" rating that is at least 20-25% higher than that peak number. That buffer is crucial. It stops you from redlining your generator and ensures you have smooth, reliable power even when you're slammed.

What Are the Biggest Equipment Mistakes to Avoid?

Learning from someone else's expensive mistakes is the cheapest education you'll ever get. The Los Angeles Food Trucks scene is tough, and a few common blunders can sink a new business fast. Here are the top five to watch out for.

- Buying Before Planning: This is the #1 mistake. Don't buy a single piece of equipment until your menu is 100% locked in. Otherwise, you'll end up with gear you don't need or that’s the wrong size for your concept.

- Underestimating Power: We just covered this, but it's worth repeating. An undersized generator is a recipe for pure chaos.

- Ignoring Workflow: Just because it fits doesn't mean it's right. Squeezing equipment in without thinking about how your crew will move creates a kitchen where nobody can work efficiently.

- Skimping on Safety: Trying to save a few bucks on your ventilation hood or fire suppression system is a terrible idea. It’s a huge safety risk and will get you an instant "fail" from the health and fire inspectors.

- Forgetting the Tape Measure: It sounds silly, but it happens all the time. People buy the perfect fridge only to find out it won't fit through the truck door. Measure your door, measure your space, measure the equipment. Twice.

Ready to build your food truck kitchen with reliable, warranty-backed equipment? LA Restaurant Equipment offers warehouse-direct pricing on everything you need, from Atosa refrigeration to a full range of cooking lines. Enjoy fast, free shipping from our Brea, California hub and explore flexible financing options to get your business rolling.

Visit us online to browse our inventory at https://larestaurantequipment.com today.